Atomizer and electronic heating evaporation sucking device

A nebulizer and atomizing core technology, which is applied in therapeutic nebulizers, inhalers, medical equipment, etc., can solve the problems of strengthening the heat dissipation of the nebulizer, so as to improve the heat dissipation performance, improve the taste experience, and maintain The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

[0035] Please refer to figure 1 , discloses an inventive electronically heated evaporative suction device 100 . The electronic heating evaporative suction device 100 includes a host 10 and an atomizer 20 , the host 10 and the atomizer 20 are electrically connected and supply power to the atomizer 20 .

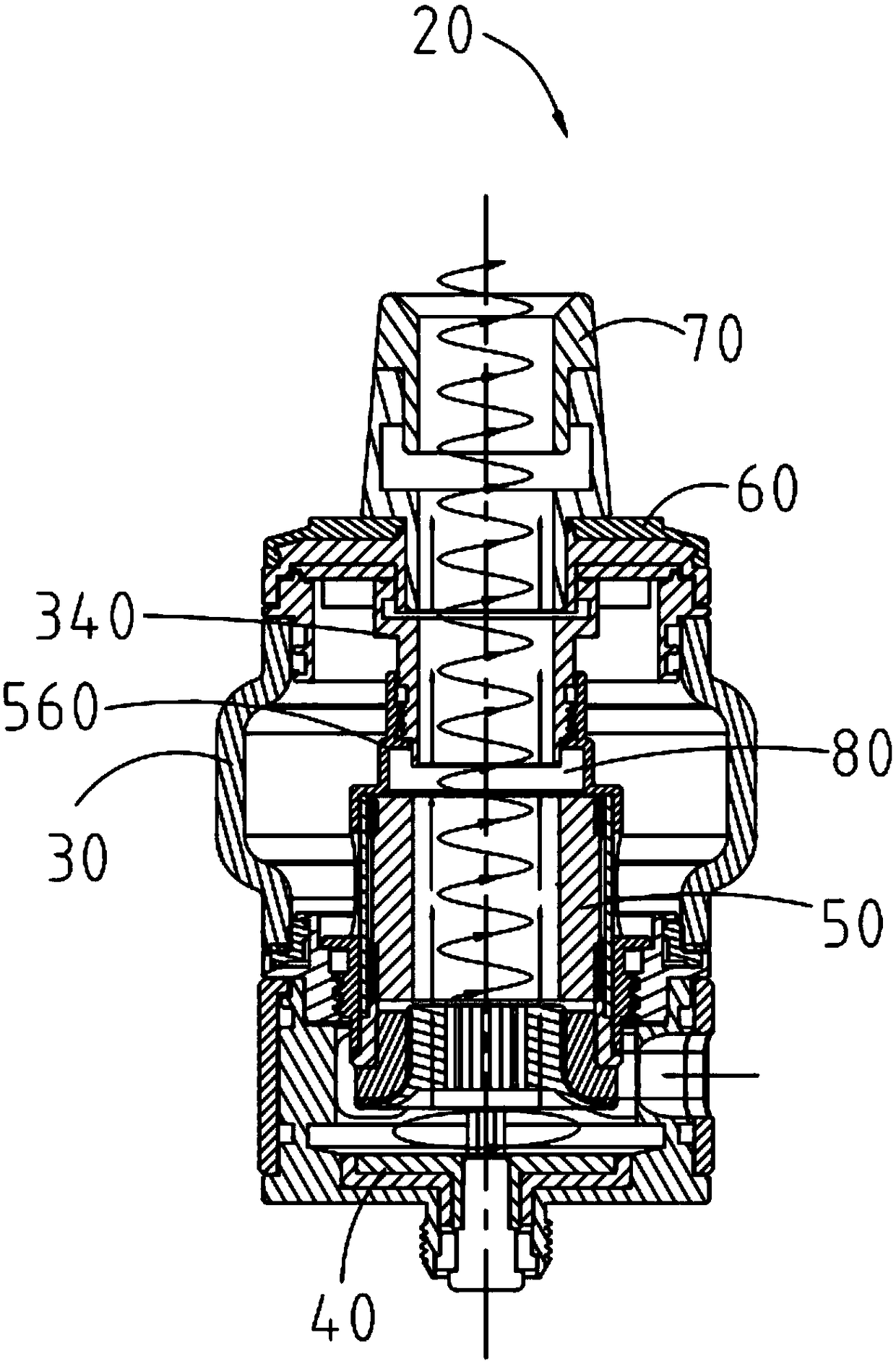

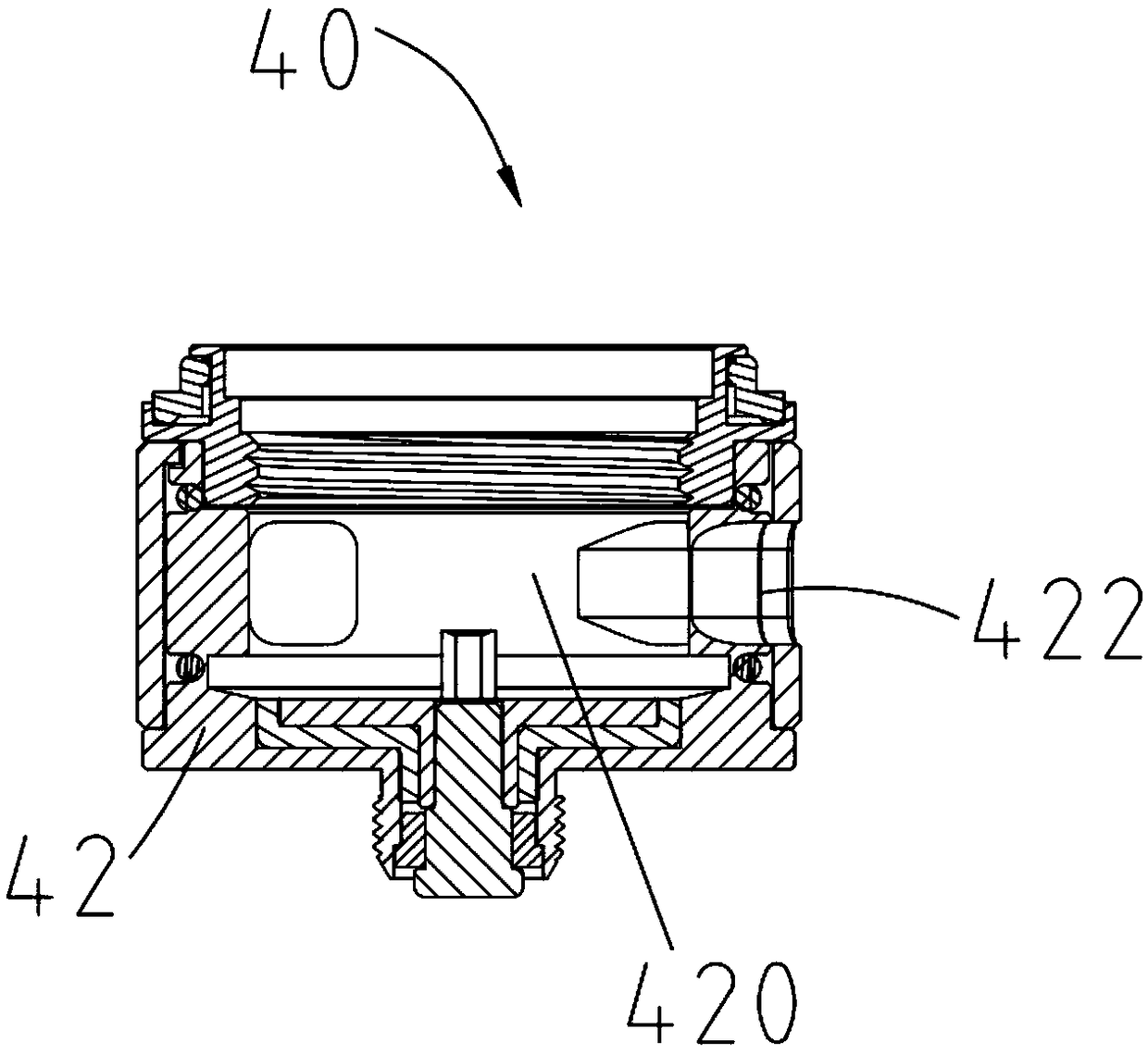

[0036] Please refer to Figure 2 to Figure 7 , the atomizer 20 includes an oil storage tank assembly 30, a base assembly 40 and an atomizing core assembly 50, the base assembly 40 includes a base body 42, and the base body 42 is provided with an accommodation chamber 420 and several air intake holes 422, the air inlet 422 communicates with the accommodation chamber 420, the atomizing core assembly 50 is installed between the oil storage bin assembly 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com