Ceramic material grinding and screening device for three-dimensional (3D) printing

A ceramic material, 3D printing technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of pressure adjustment that cannot be ground, particle blocking in the screening process, etc., to achieve novel structure, improve effect, and prevent clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

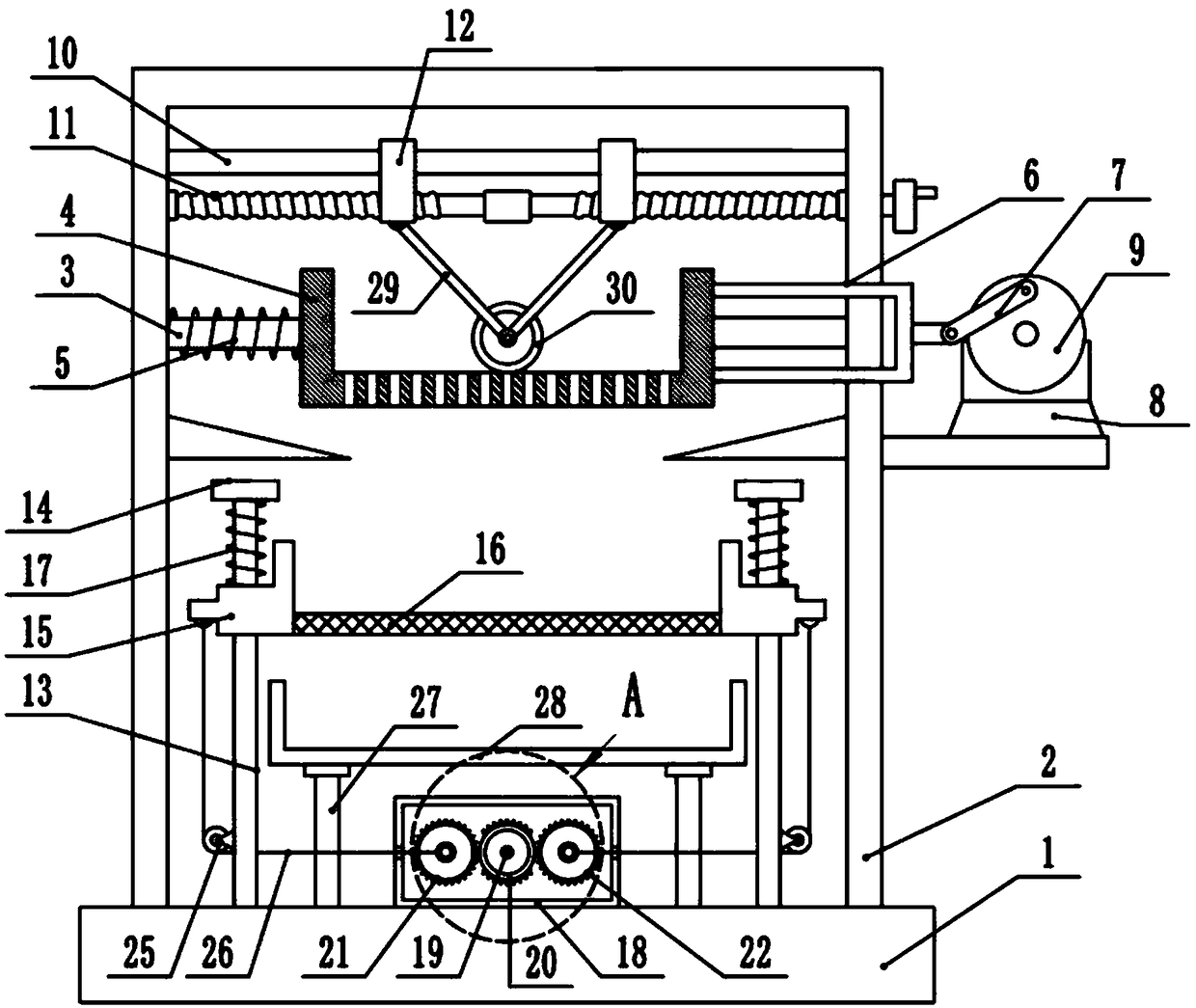

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

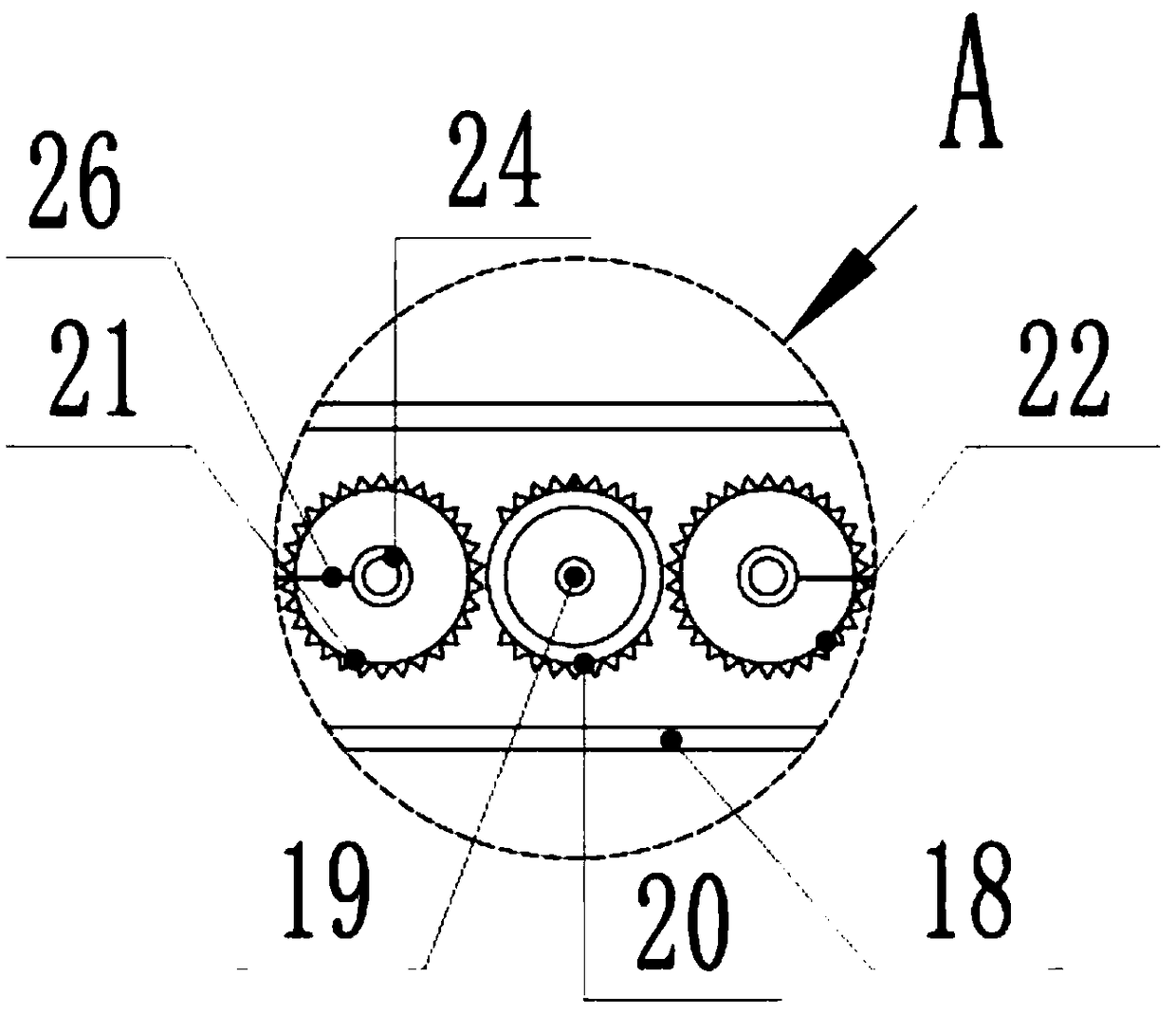

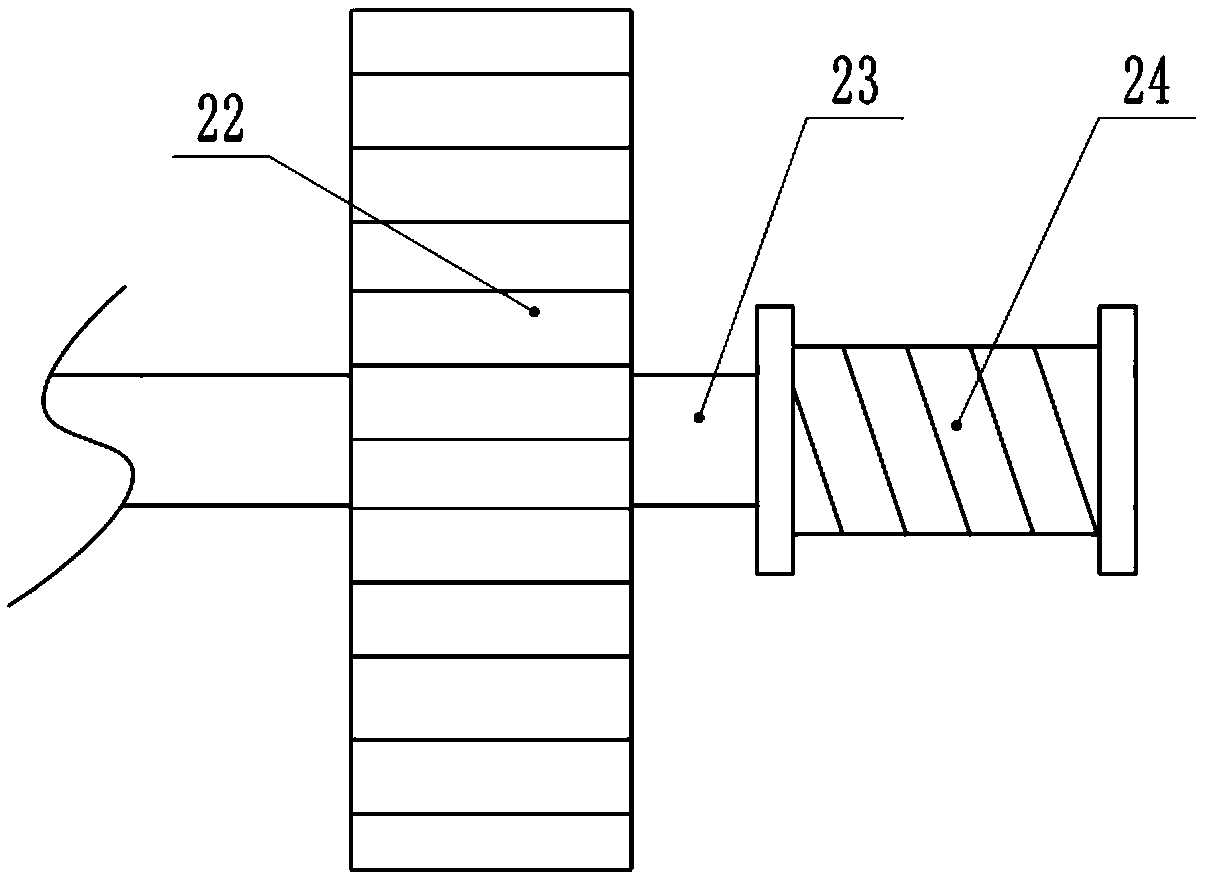

[0020] see Figure 1-3 , a ceramic material grinding and screening device for 3D printing, comprising a base 1, a grinding box 2, a grinding boat 4, a receiving tank 28 and a grinding wheel 30, the base 1 is fixed with a grinding box 2 by screws, The front side of the grinding box 2 is hingedly equipped with a split door (not shown in the figure), and at least two sets of sliding bars 3 are installed horizontally inside the grinding box 2, and the grinding boat 4 is slidingly installed on the sliding bars 3. A primary sieve plate is installed at the bottom of the ship 4, and a circular sieve hole is opened on the surface of the primary sieve plate. Through the center of the spring 5, the outer wall on the right side of the grinding ship 4 is also fixedly welded with a first connecting rod 6, the first connecting rod 6 is horizontal to the right an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com