Reaction kettle for treating animal solid waste

A reactor and animal technology, which is applied in the field of reactors for treating animal solid waste, can solve the problems of misalignment between the main shaft and the reducer, incomplete drying, and long reaction time, so as to improve the drying effect and reduce the number of maintenance , the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

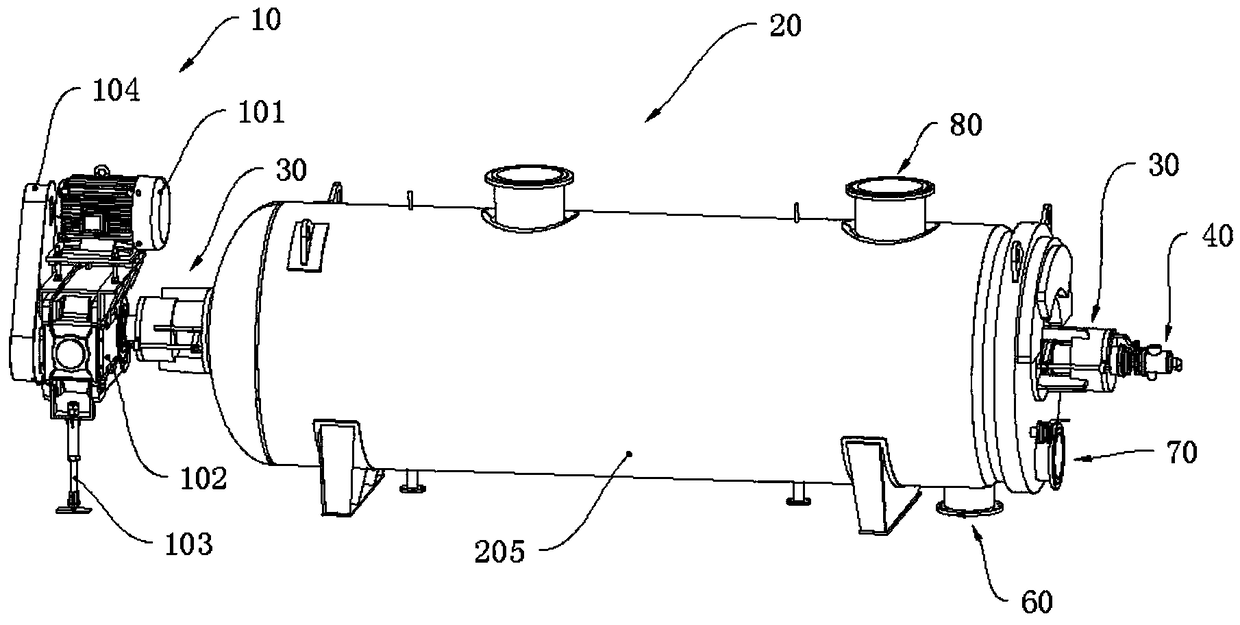

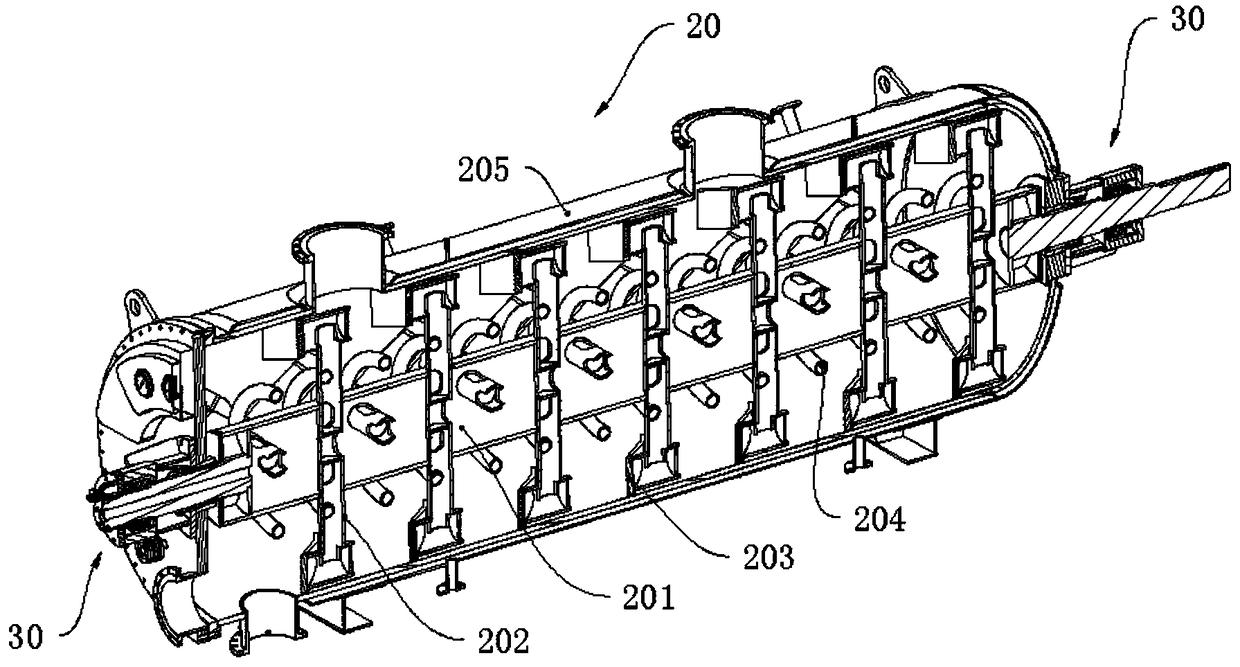

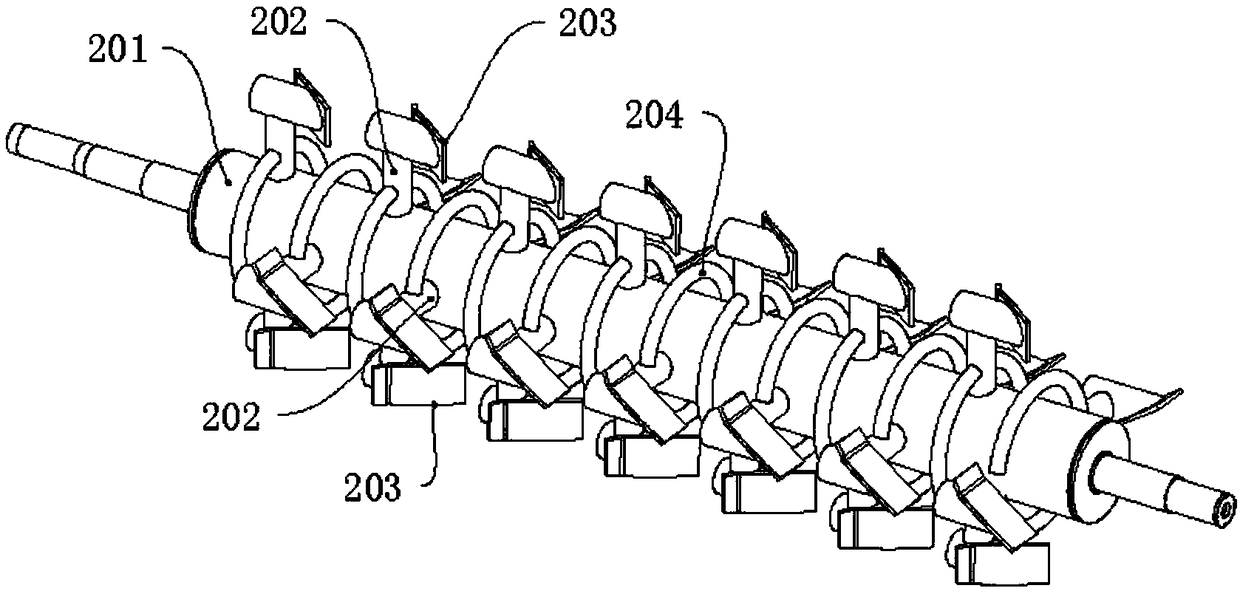

[0027] Such as Figure 1 to Figure 8 As shown, a reaction kettle for treating animal solid waste includes a rotating stirring device 20 and a power transmission device 10. The rotating stirring device 20 includes a housing 205, a rotating main shaft 201, and a coil 204, which are arranged on the surrounding wall of the rotating main shaft 201. The stirring shaft 202; the rotating main shaft 201, the coil tube 204 and the stirring shaft 202 are respectively arranged in the housing 205, and the adjacent stirring shafts 202 are staggered, and the staggered angle between the adjacent stirring shafts 202 is 0 degrees to 90 degrees. Preferably 90 degrees. The end of the stirring shaft 202 is provided with stirring teeth 203, and the angle between the stirring teeth 203 and the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com