Rotary-table round tube cutting machine

A technology for cutting machines and round pipes, applied in welding/cutting auxiliary equipment, tubular objects, auxiliary devices, etc., can solve the problems of high motor load, high power consumption of equipment, difficult control, etc., and achieve high cutting efficiency and safe operation stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

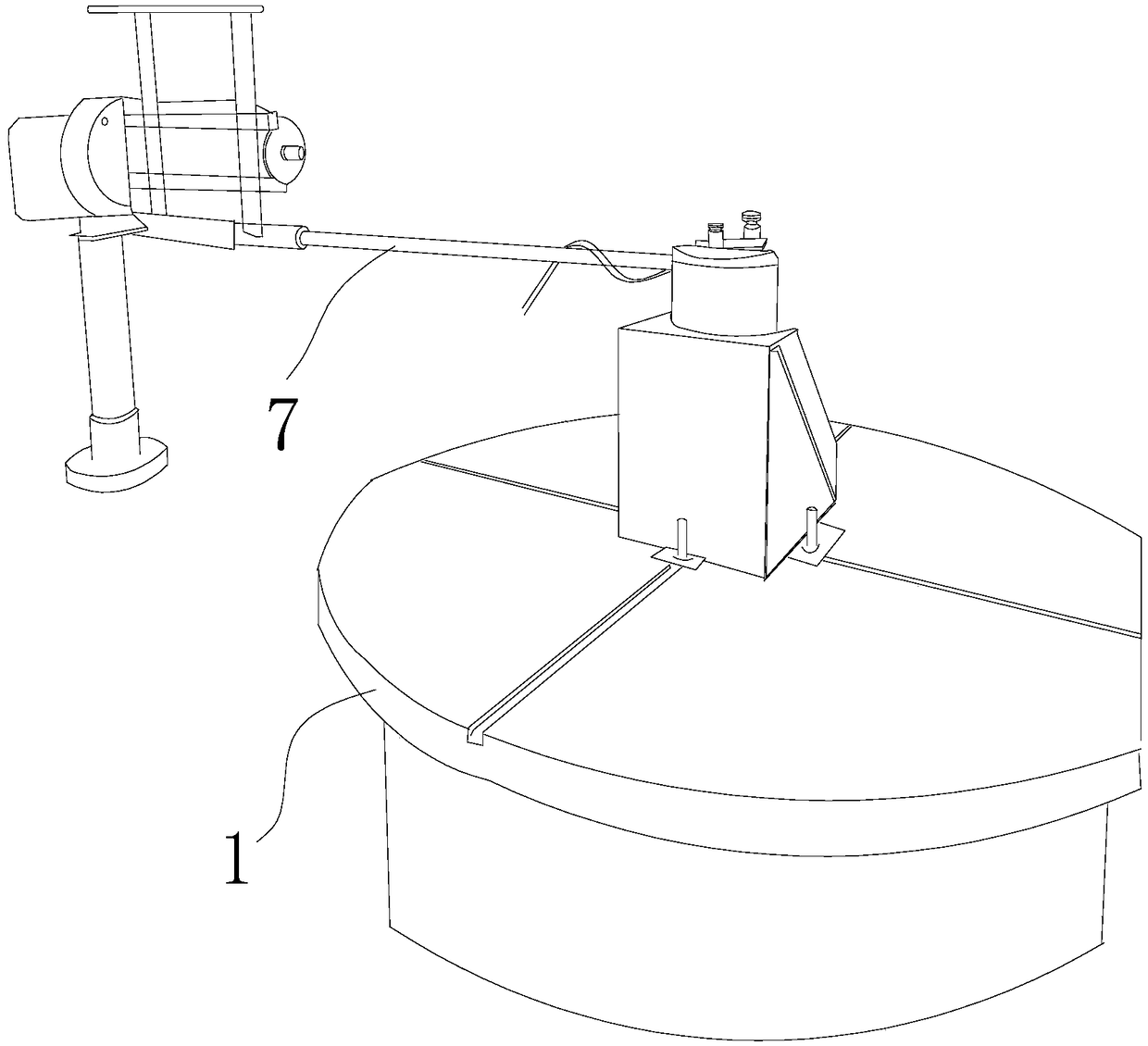

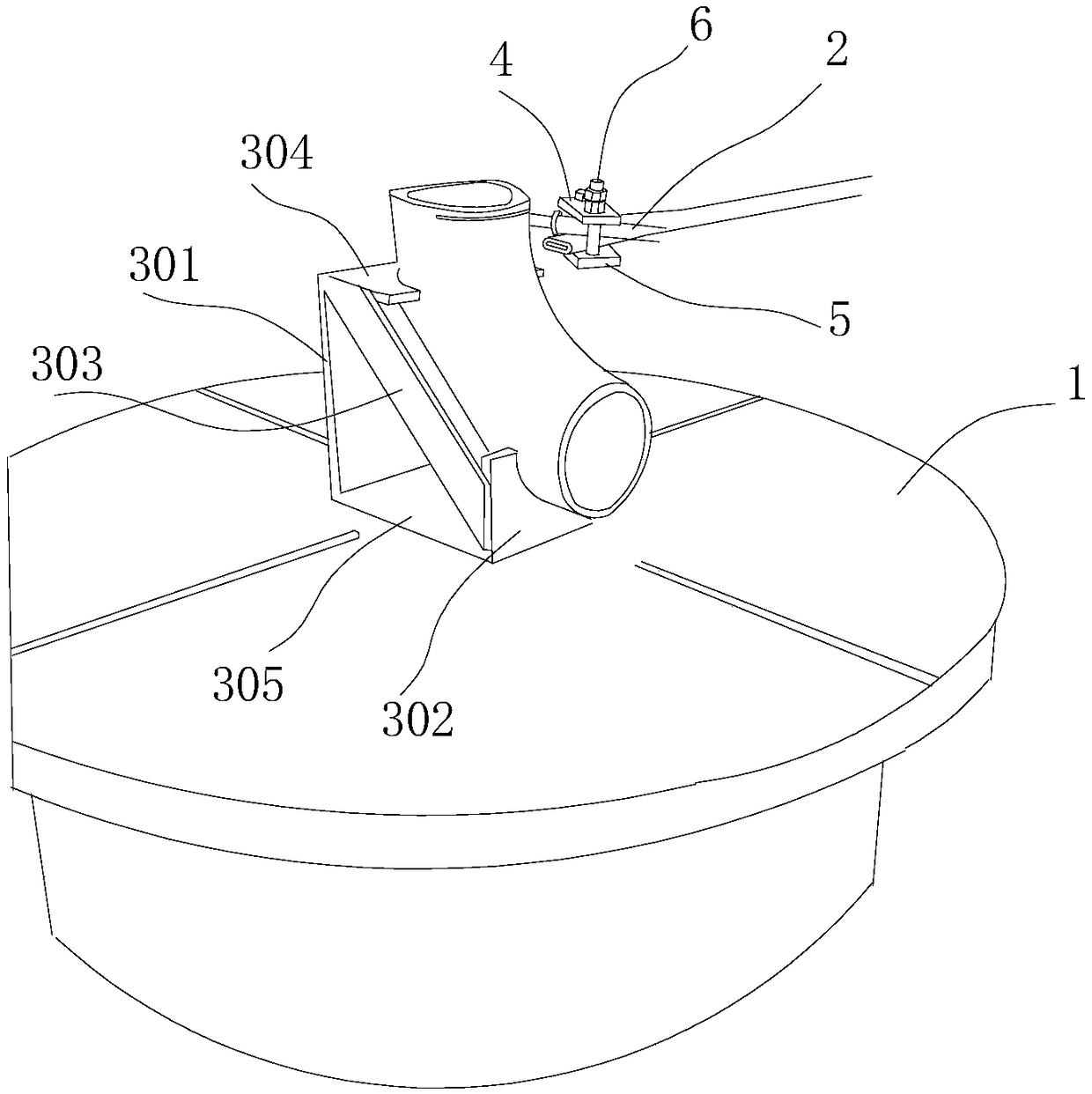

[0013] Such as figure 1 As shown, the round pipe cutting machine of this embodiment includes a turntable 1 and a cutting torch 2 for fixing the round pipe. The turntable is equipped with a motor that drives the rotation. Removably arranged on the support 7, the cutting rob 2 is installed on the support 2 by the upper and lower splints 4,5, and the upper and lower splints 4,5 are connected by bolts 6. By adjusting the position of the cutting gun to make contact with the round tube to be cut, the position of the cutting gun 2 is fixed during cutting, and the turntable 1 drives the round tube to rotate, and the cutting gun performs circumferential cutting on the round tube.

[0014] The above-mentioned turntable 1 is provided with a fixed seat for fixing the round pipe to be cut. The fixed seat includes a base plate 305, and the opposite sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com