Electromechanical cylindrical short tube derusting device

A technology of cylindrical and short tubes, which is applied in the field of electromechanical cylindrical short tube derusting devices, which can solve the problems of easily injured hands, easy residual impurities in short tubes, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

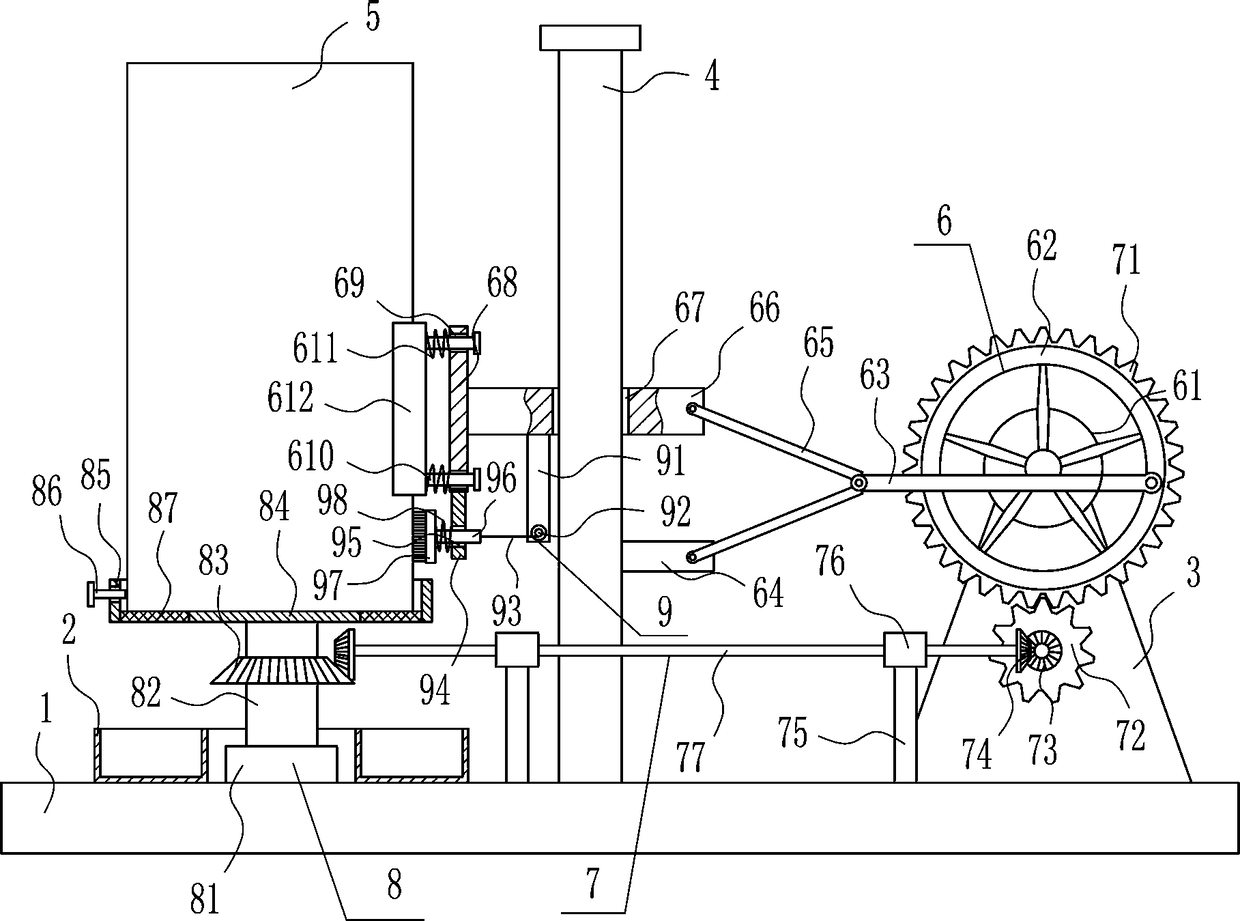

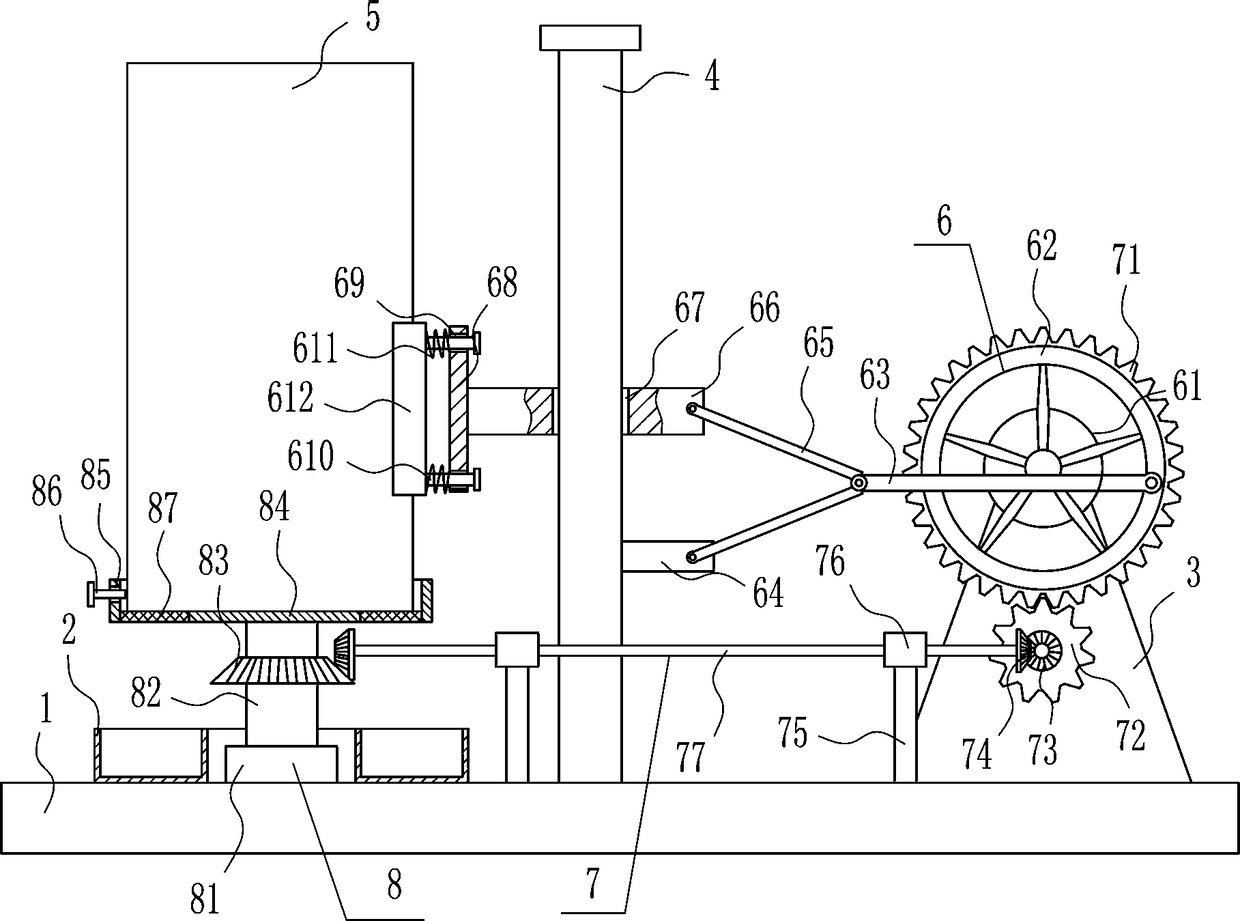

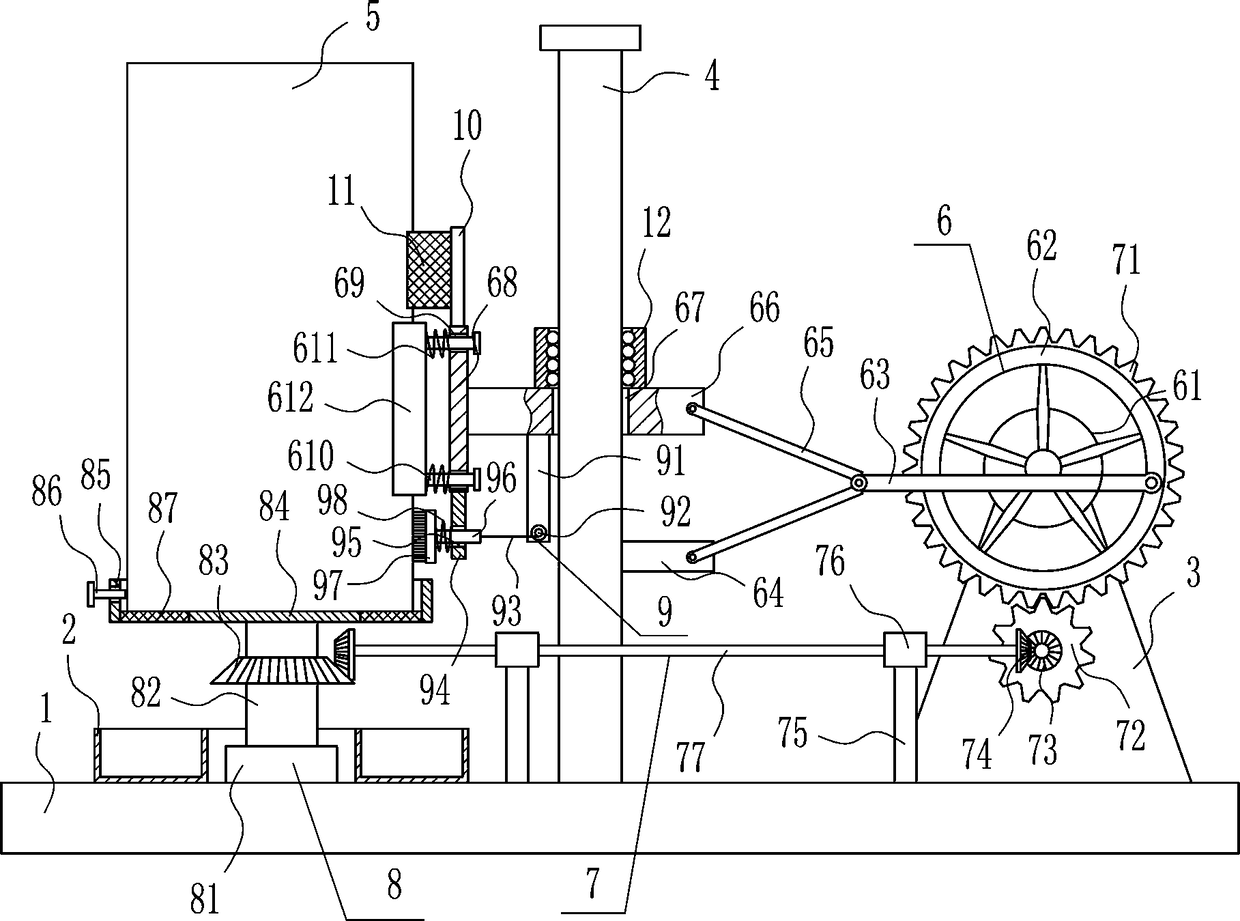

[0026] A kind of electromechanical cylindrical short tube derusting device, such as Figure 1-3 As shown, it includes a bottom plate 1, an annular frame 2, a support seat 3, a vertical rod 4, a derusting device 6, a transmission device 7 and a fixing device 8, a vertical rod 4 is installed in the middle of the top of the bottom plate 1, and a Support base 3, a derusting device 6 is provided between the top of the support base 3 and the vertical bar 4, a transmission device 7 is provided in the middle of the top of the bottom plate 1, the transmission device 7 is connected with the derusting device 6, and a fixing device is provided on the left side of the top of the bottom plate 1 8. The fixing device 8 is located at the bottom left of the derusting device 6, and the ring frame 2 is installed on the left side of the top of the bottom plate 1, and the fixing device 8 is located at the center of the ring frame 2.

Embodiment 2

[0028] A kind of electromechanical cylindrical short tube derusting device, such as Figure 1-3 As shown, it includes a bottom plate 1, an annular frame 2, a support seat 3, a vertical rod 4, a derusting device 6, a transmission device 7 and a fixing device 8, a vertical rod 4 is installed in the middle of the top of the bottom plate 1, and a Support base 3, a derusting device 6 is provided between the top of the support base 3 and the vertical bar 4, a transmission device 7 is provided in the middle of the top of the bottom plate 1, the transmission device 7 is connected with the derusting device 6, and a fixing device is provided on the left side of the top of the bottom plate 1 8. The fixing device 8 is located at the bottom left of the derusting device 6, and the ring frame 2 is installed on the left side of the top of the bottom plate 1, and the fixing device 8 is located at the center of the ring frame 2.

[0029] The derusting device 6 includes a motor 61, a rotating di...

Embodiment 3

[0031] A kind of electromechanical cylindrical short tube derusting device, such as Figure 1-3 As shown, it includes a bottom plate 1, an annular frame 2, a support seat 3, a vertical rod 4, a derusting device 6, a transmission device 7 and a fixing device 8, a vertical rod 4 is installed in the middle of the top of the bottom plate 1, and a Support base 3, a derusting device 6 is provided between the top of the support base 3 and the vertical bar 4, a transmission device 7 is provided in the middle of the top of the bottom plate 1, the transmission device 7 is connected with the derusting device 6, and a fixing device is provided on the left side of the top of the bottom plate 1 8. The fixing device 8 is located at the bottom left of the derusting device 6, and the ring frame 2 is installed on the left side of the top of the bottom plate 1, and the fixing device 8 is located at the center of the ring frame 2.

[0032] The derusting device 6 includes a motor 61, a rotating di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com