Spreading device and method for stone powder fiber composite boards

A fiber composite board, stone powder technology, applied in lamination devices, chemical instruments and methods, lamination and other directions, can solve problems such as low production efficiency, pollution, waste of raw materials, etc., to reduce energy consumption, reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

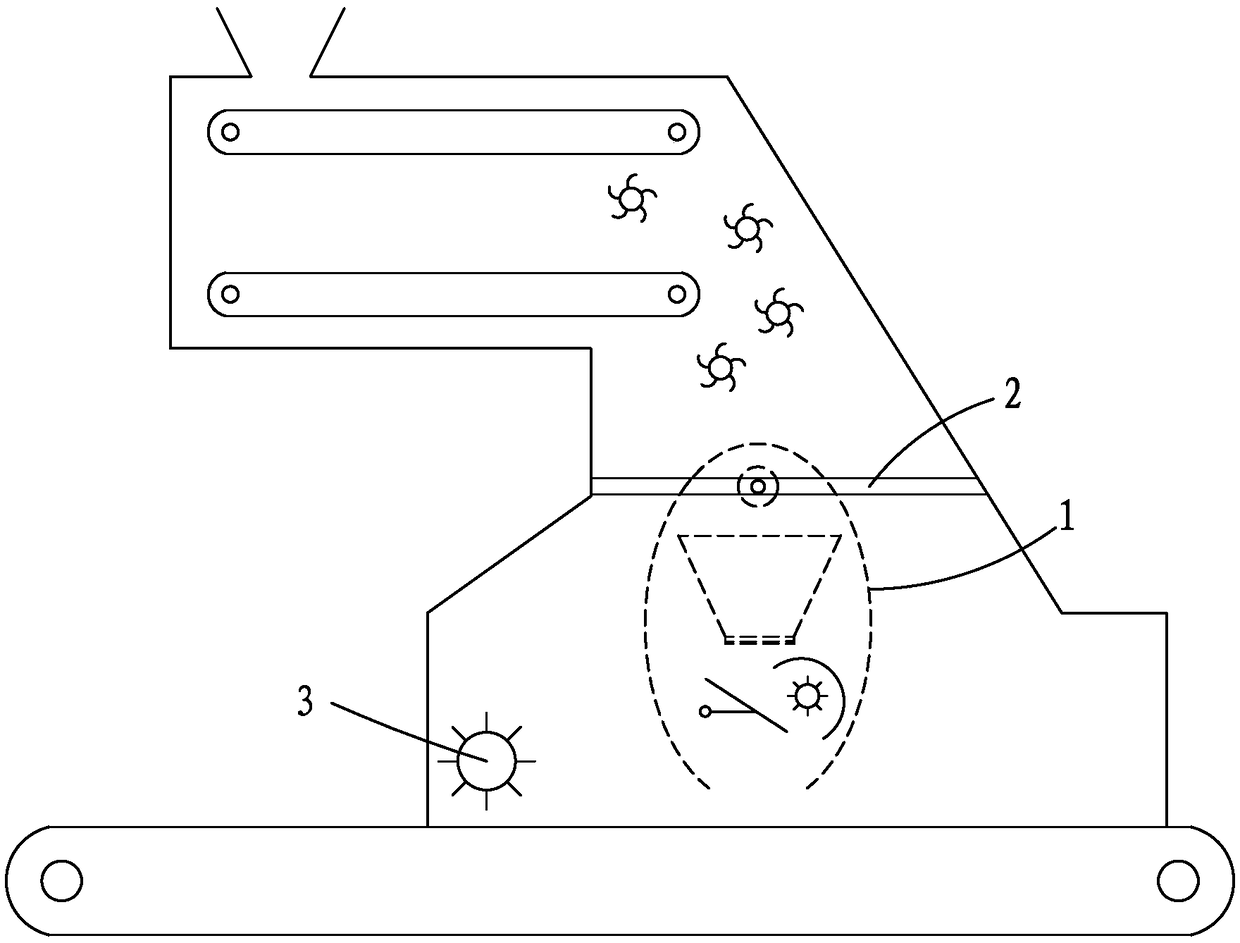

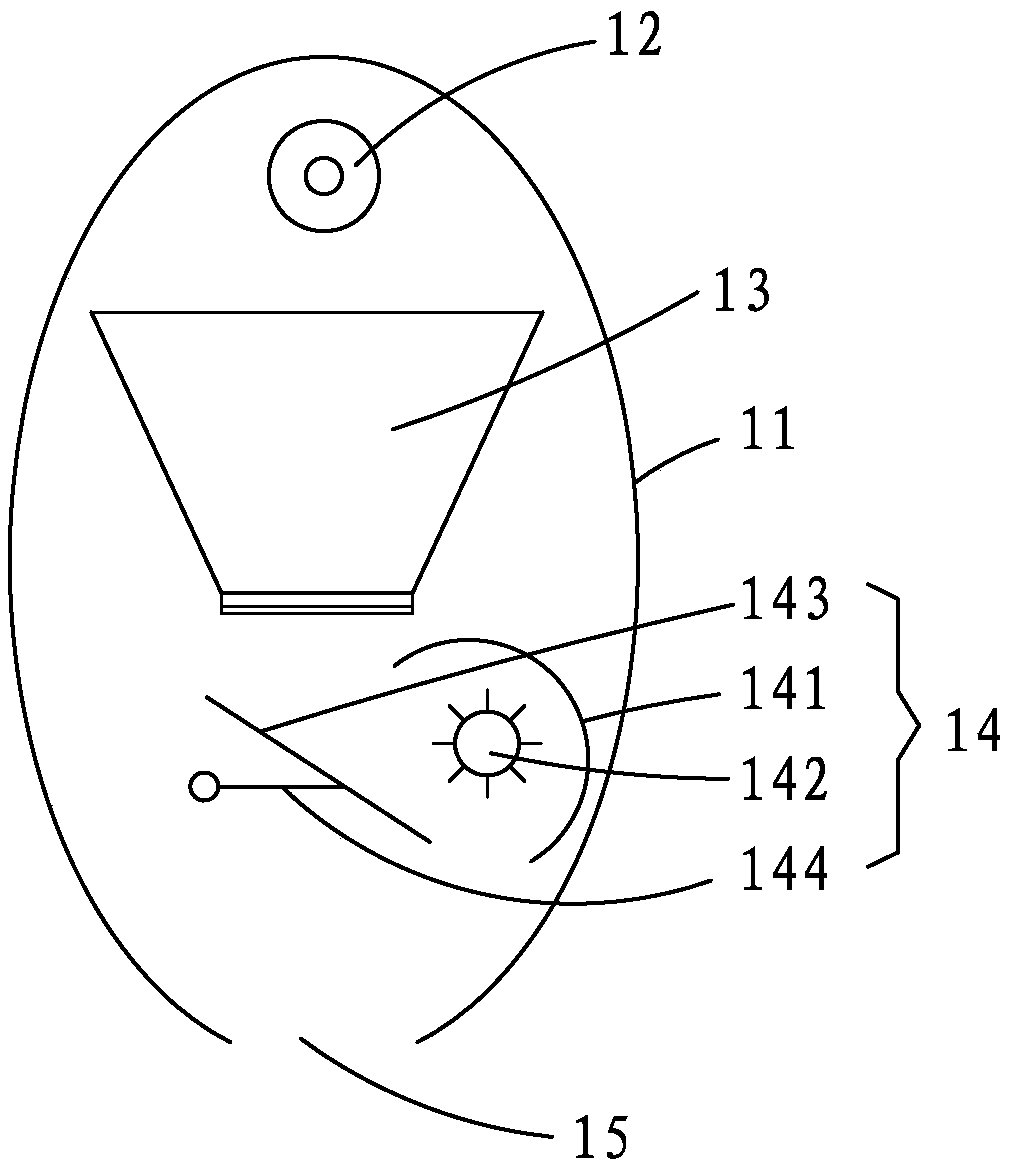

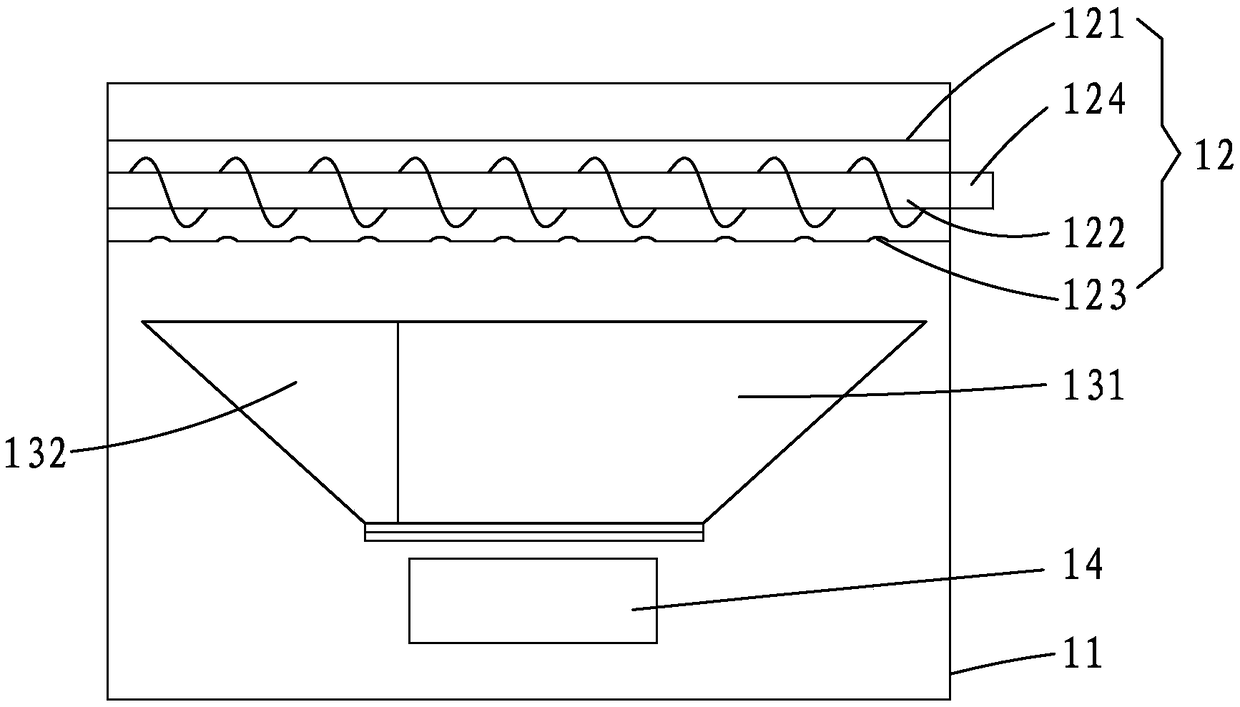

[0027] like Figure 1-3 As shown, a pavement device for stone powder fiber composite board includes a feed conveying device, a pavement forming device and a casing, and the pavement forming device includes a stone powder paving device 1 and a casing below the casing. The slab transportation device; the stone powder paving device 1 includes a rugby ball-shaped casing 11 with a longitudinal section, the upper end of the casing 11 is pointed and closed, and the lower end is open. A feeding screw conveyor 12, a hopper 13, a material guide unit 14, and a stone powder outlet 15 are provided in sequence.

[0028] The feeding screw conveyor 12 includes a feeding cylinder 121 and a screw 122 located in the feeding cylinder 121, the lower end of the feeding cylinder 121 is provided with several feeding through holes 123 at intervals; the feeding cylinder 121 runs through the rugby ball shell One end of the body 11 and extending to the outside of the casing is provided with a stone powd...

Embodiment 2

[0045] Different from Embodiment 1, the hopper 13 of the stone powder paving device 1 is not divided into a large hopper 131 and a small hopper 132 by a partition, and there is no material guide unit 14 .

[0046] The stone powder has a particle size of 350 mesh and is covered with a layer of glue that is the same as the fiber covering, with a water content of 3.5%.

[0047] After testing, the density of the 15mm low-density fiberboard prepared in this example is 550 kg / m3, and its performance index can reach the furniture-type medium-density fiberboard used in the dry state in the national standard for medium-density fiberboard (GB / T 11718-2009). The performance requirement index of fiberboard, the detection value of its performance index is as follows:

[0048]

Embodiment 3

[0050] The difference from Example 1 is that the stone powder paving device includes 2 stone powder feeding areas 124 (one left and one right symmetrically arranged), 2 feeding screws 122, 4 large hoppers 131, 4 Small hopper 132, 4 discharge valves for large hoppers, 4 discharge valves for small hoppers, 4 discharge guide plates 143 and corresponding adjustment rods 144, 4 pulleys 142, 4 curved guide plates 141, 1 stone powder outlet 15, the device is provided with a vibrating motor for driving the vibration of the stone powder paving device.

[0051] The stone powder has a particle size of 600 mesh and is covered with a layer of glue that is the same as the fiber covering, with a water content of 4%. ·

[0052] After testing, the density of the 18mm low-density fiberboard prepared in this example is 570 kg / m3, and its performance index can reach the furniture-type medium-density fiberboard used in the dry state in the national standard for medium-density fiberboard (GB / T 117...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com