Laying device and method of manufacturing fiberboard by utilizing sanding powder to replace precured layer

A technology of pre-cured layer and sanding powder, which is applied in applications, household components, flat products, etc., can solve the problems of production enterprise losses, etc., and achieve the effect of reducing energy consumption, reducing consumption, and reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

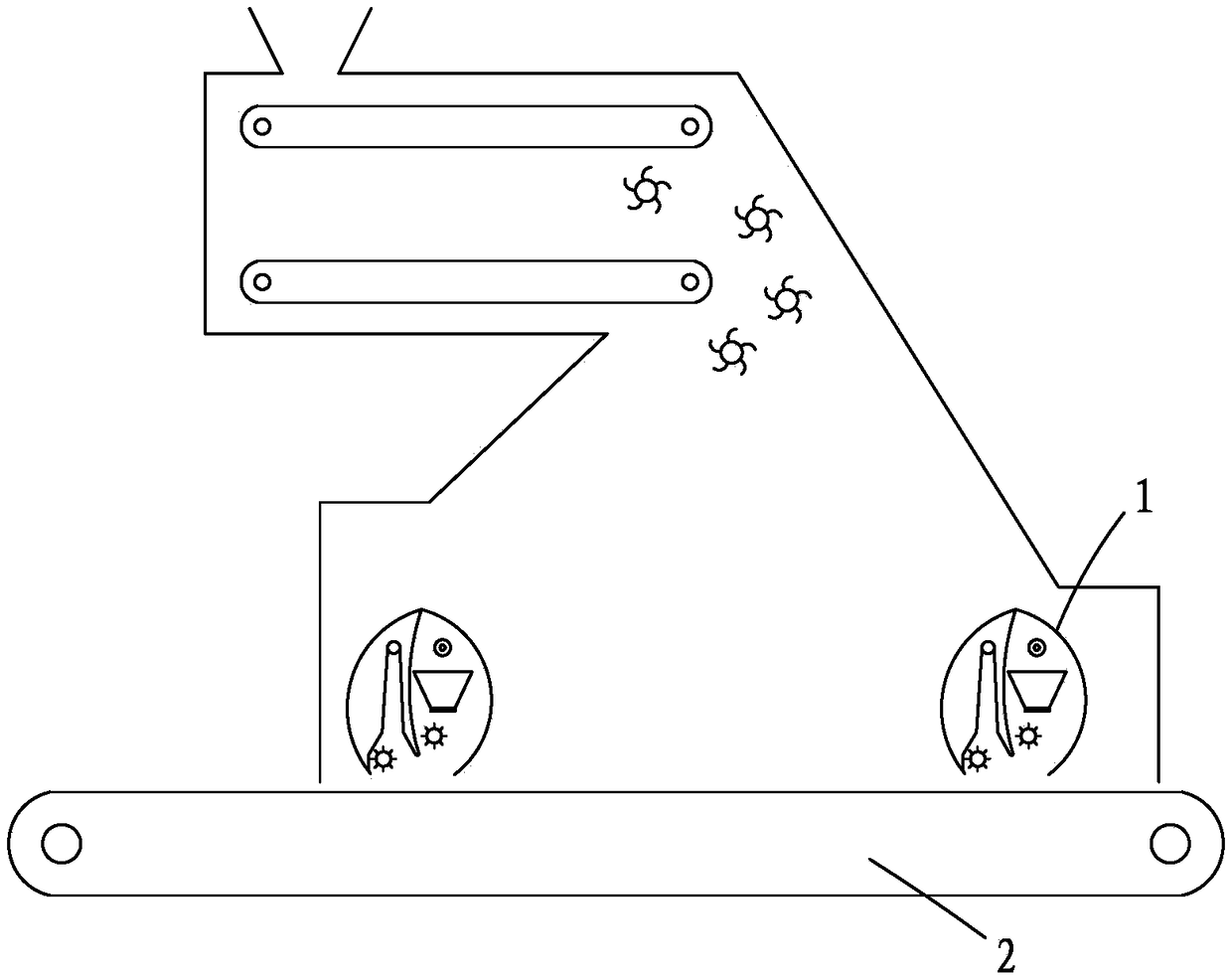

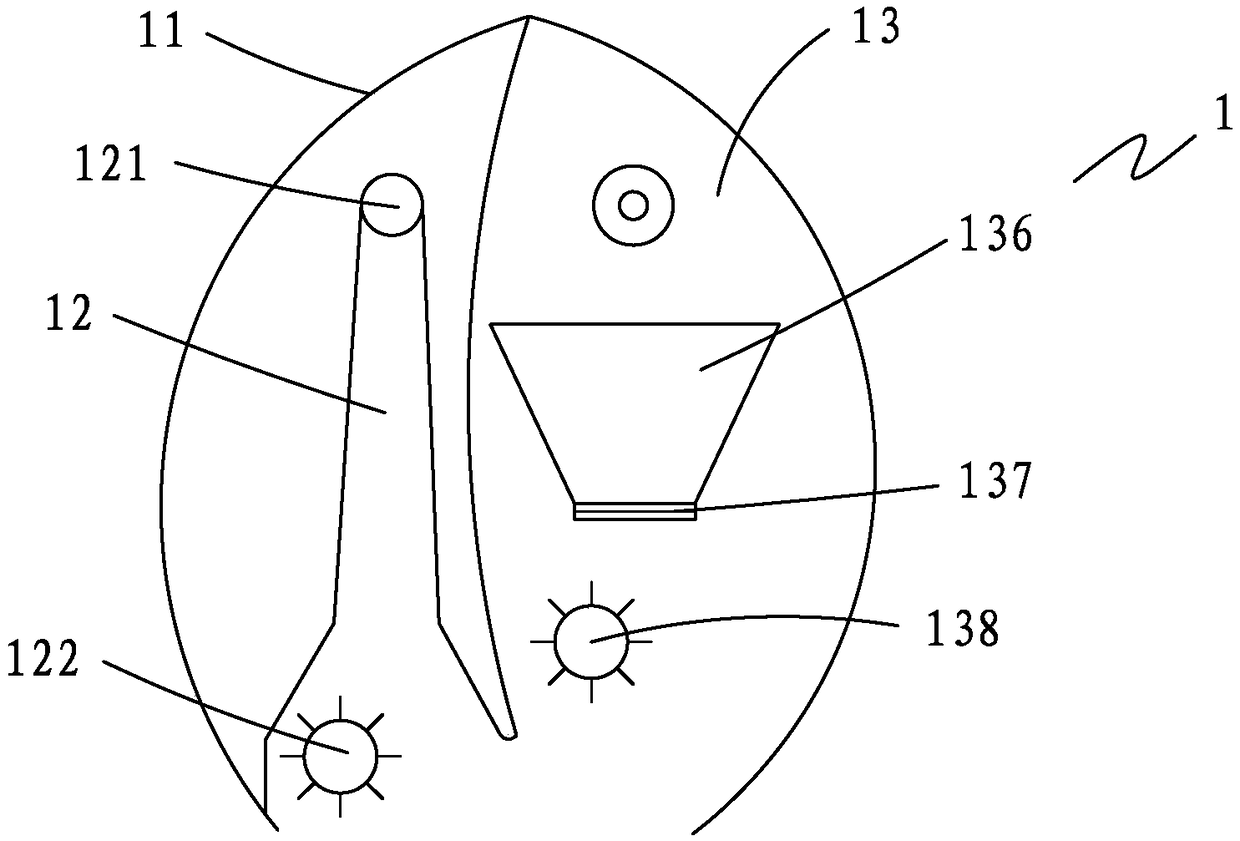

[0040] A method for preparing fiberboards by using sanding powder instead of a pre-cured layer, specifically including wood chipping, fiber preparation, fiber sizing, dry fiber + sanding powder layered paving, pre-pressing, hot pressing, and rough board treatment steps .

[0041] The sanding powder is taken from the coarse sand frame of the fiberboard sanding machine, which is the largest particle size in the sanding powder, and the particles cover the produced adhesive.

Embodiment 1

[0043] The surface layer and the bottom sanding powder layer are paved at the same time. The surface layer sanding powder paving device is located outside the paving machine shell. The sanding powder is taken from the coarse sand frame of the fiberboard sanding machine, which is the particle size of the sanding powder. The largest one, the particle-covered adhesive, has a moisture content of 13%-20%.

[0044] The adhesive is a melamine-modified urea-formaldehyde resin adhesive with a solid content of 48-50% liquid adhesive. The sanding powder: covered urea-formaldehyde adhesive: water weight mixing ratio is: 1000kg: 80kg: 157kg.

[0045] In the fiber sizing step, the weight ratio of fiber and adhesive is 10:1.2.

[0046] The adhesive is a melamine-modified urea-formaldehyde resin adhesive or an isocyanate adhesive.

[0047] The molar ratio of formaldehyde to urea in the melamine-modified urea-formaldehyde resin adhesive is 1.2:1, and melamine accounts for 2% of the rubber ma...

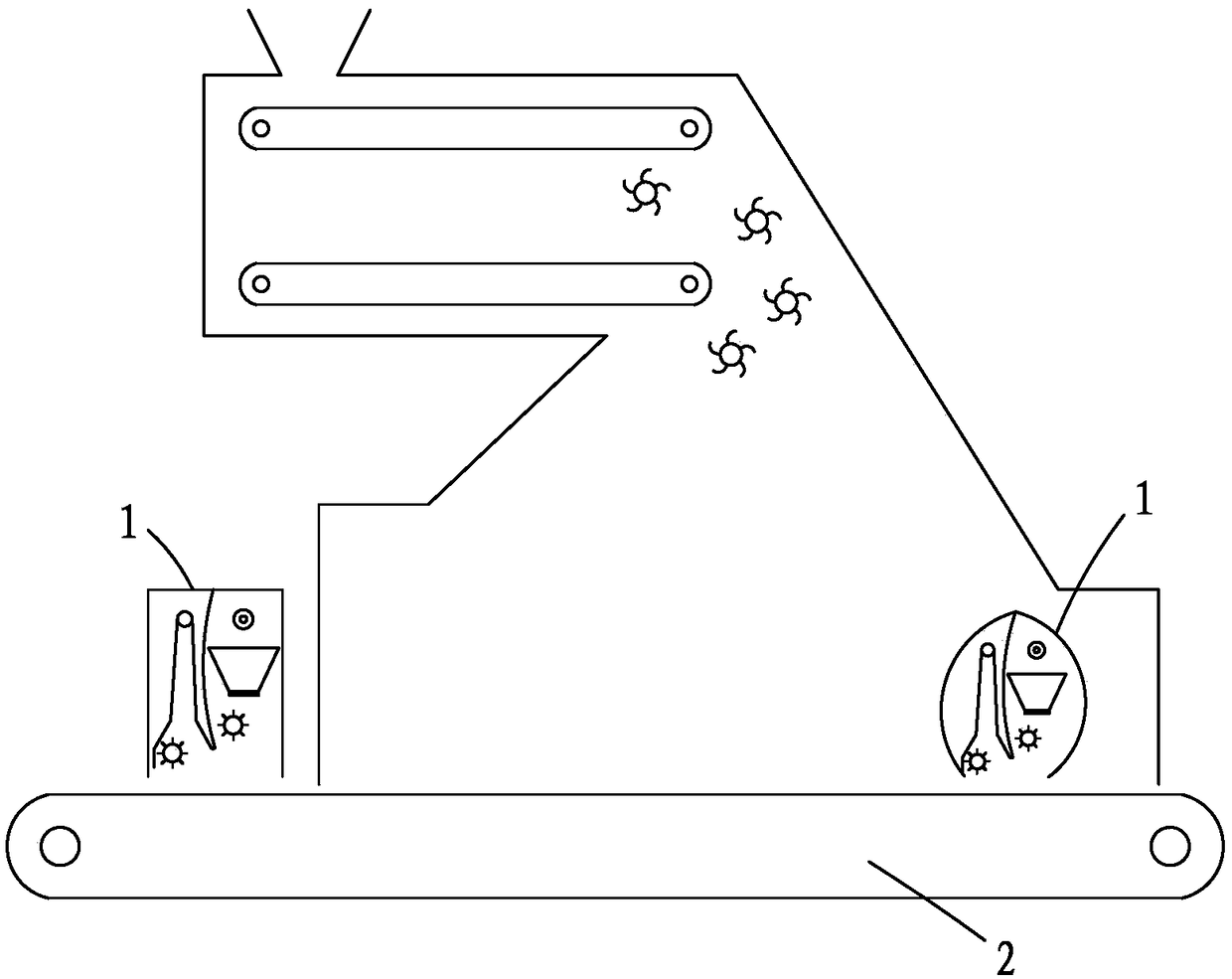

Embodiment 2

[0052] The difference from Example 1 is that the surface layer and the bottom sanding powder layer are paved at the same time, and the surface layer sanding powder paving device is located at the paving front line in the paving machine shell. The sanding powder: covered urea-formaldehyde adhesive: water weight mixing ratio is: 1000kg: 110kg: 94.5kg.

[0053] In the fiber sizing step, the weight ratio of fiber and adhesive is 10:1.6.

[0054] The adhesive is a melamine-modified urea-formaldehyde resin adhesive or an isocyanate adhesive.

[0055] The molar ratio of formaldehyde to urea in the melamine-modified urea-formaldehyde resin adhesive is 1.2:1, and melamine accounts for 4% of the rubber material.

[0056] The process parameters in the hot pressing step are: the hot pressing temperature is 210°C, the closing time of the hot pressing machine is 5.5 seconds, the hot pressing time is 105 seconds, the hot pressing pressure is 0-3.2 MPa, and the hot pressing coefficient is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com