Electric heating composite board preparation method

A composite board, electric heating technology, applied in the direction of flat products, household components, household appliances, etc., can solve the problems of raw material waste, low production efficiency, high labor intensity, etc., to reduce production costs, reduce energy consumption, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

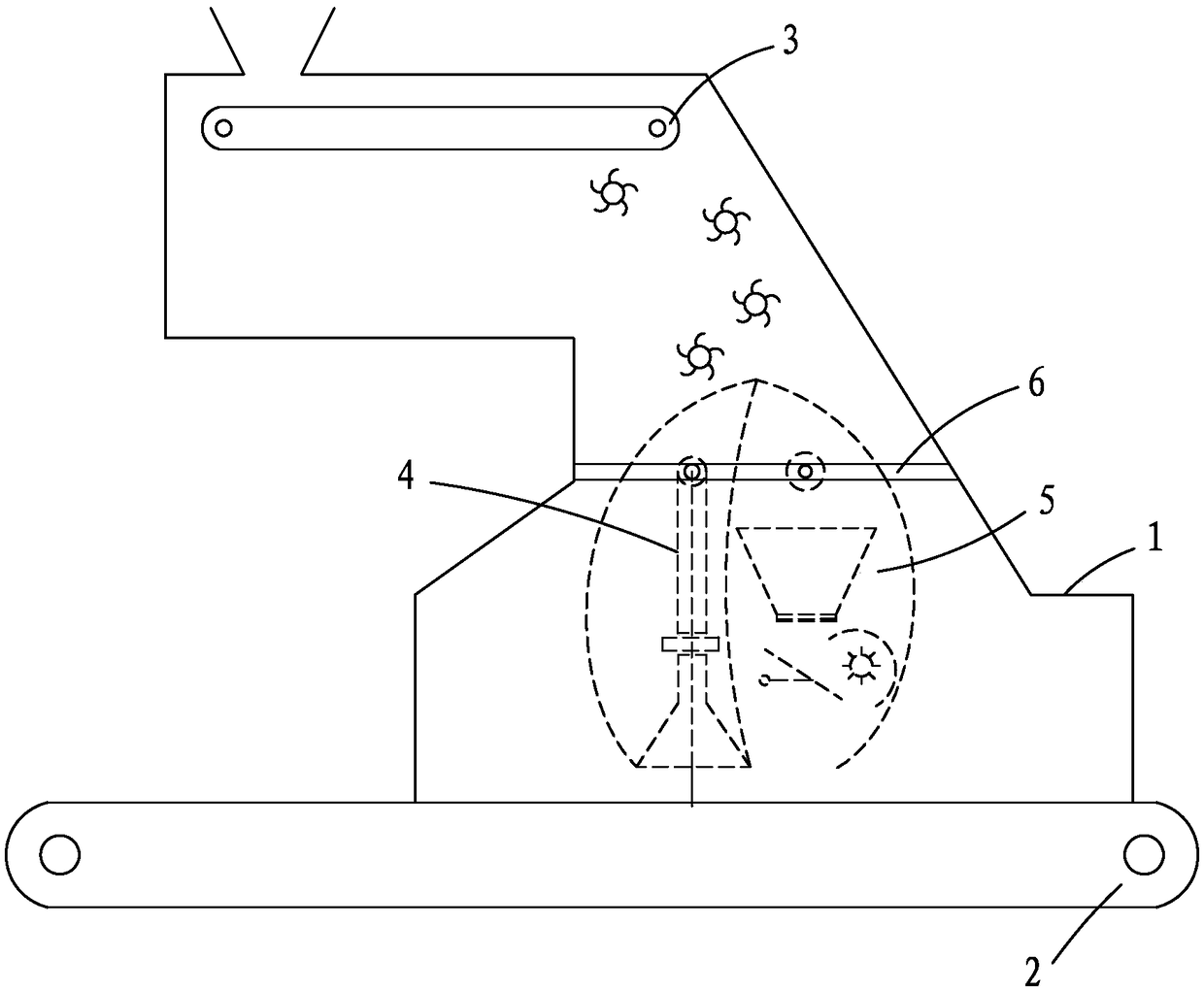

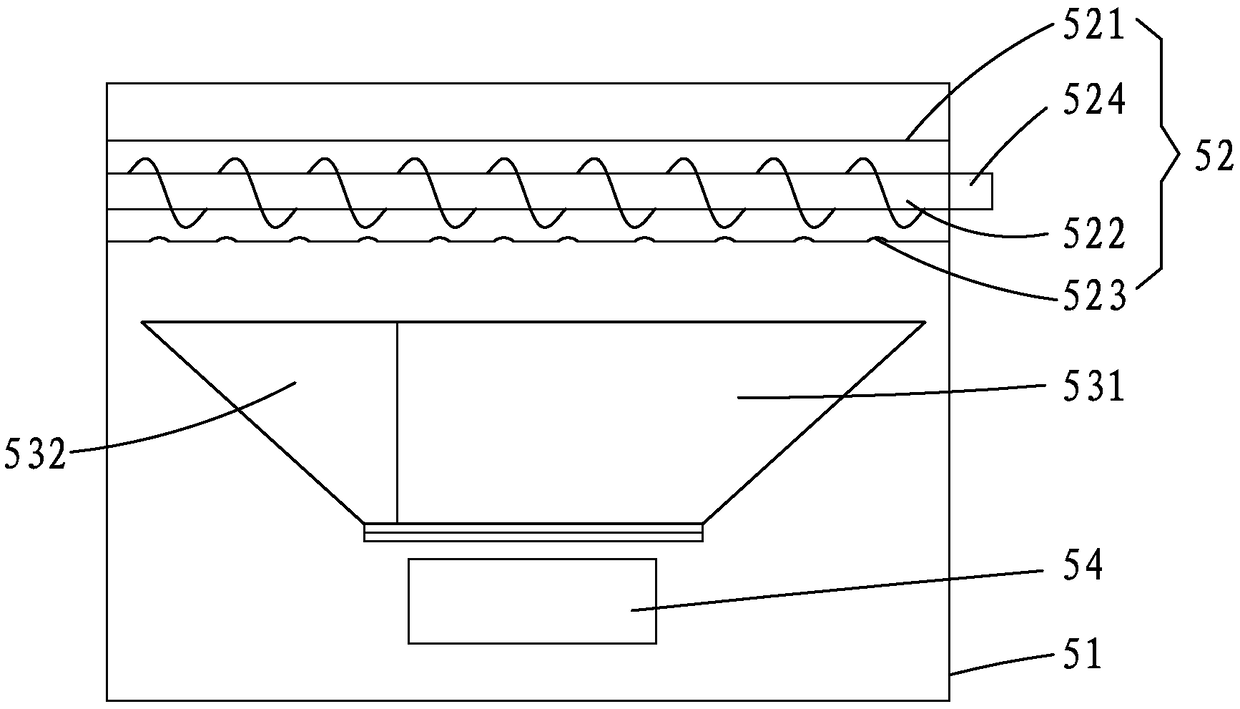

[0028] Such as figure 1 As shown, a pavement device for electrothermal composite panels includes a casing 1 and a slab transport device 2 located below the casing 1, and the casing 1 is sequentially provided with a fiber feeding and conveying device 3, A conductive heating layer paving device, the conductive heating layer paving device includes a football-shaped outer casing with a longitudinal section, the upper end of the outer casing is pointed and closed, and the lower end is open, and electric heating wires are arranged in parallel at intervals inside the outer casing. Installing device 4, heat conduction layer paving device 5.

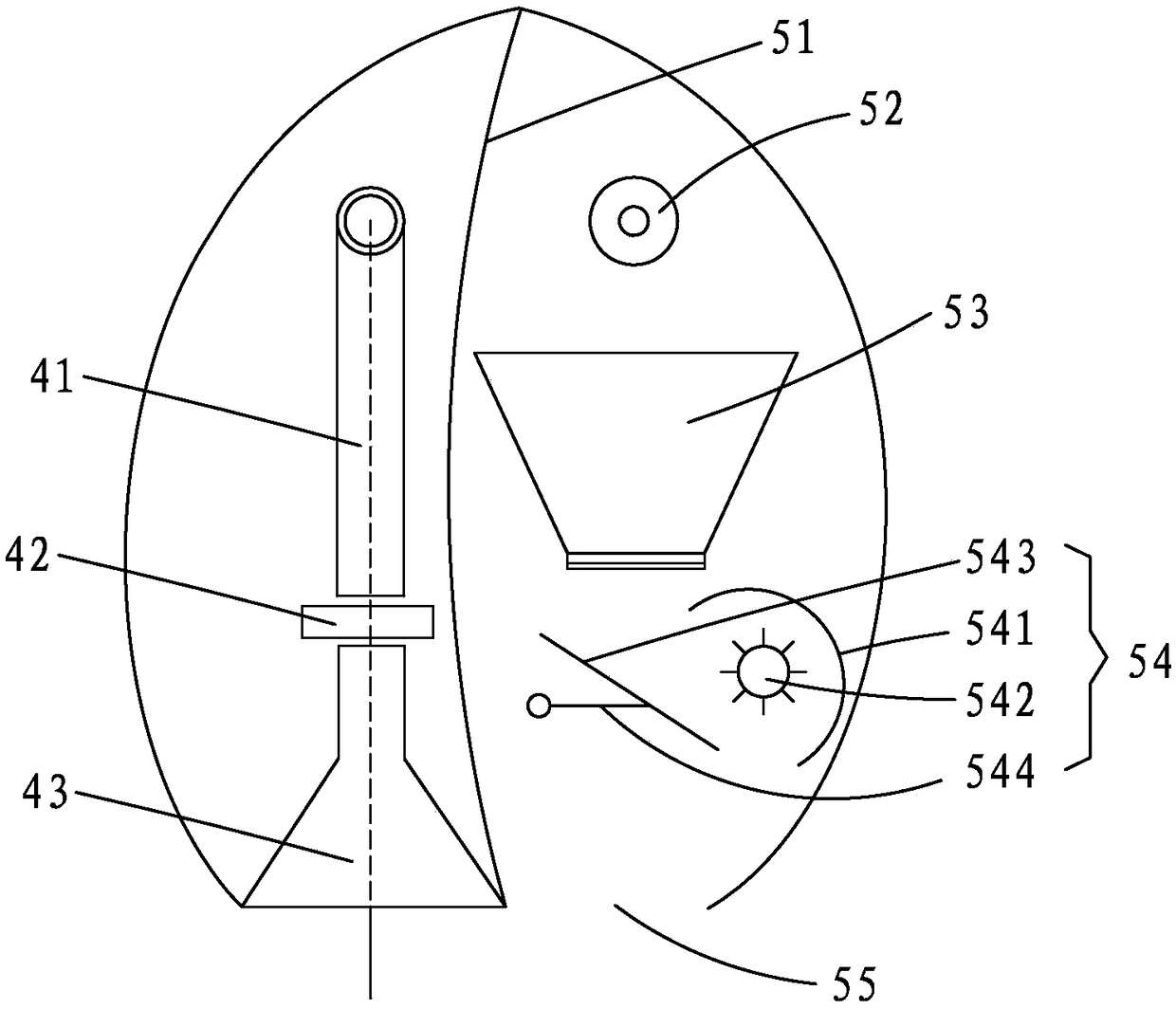

[0029] Such as figure 2 , Figure 4 As shown, the heating wire laying device 4 is sequentially provided with a heating wire conveying mechanism 41 , a heating wire automatic cutting mechanism 42 and a heating wire outlet pipe 43 from top to bottom. The heating wire delivery mechanism 41 includes an inverted L-shaped fixed tube 411 and a turni...

Embodiment 2

[0048] Different from Embodiment 1, the hopper 53 of the heat-conducting layer paving device 1 is not divided into a large hopper 531 and a small hopper 532 by a partition, and there is no material guide unit 54 .

[0049] The carbon crystal powder has a particle size of 350 meshes, and the surface of the particles is first covered with a layer of far-infrared emitting agent, and then covered with a layer of glue that is the same as that of the fiber, with a water content of 3.5%.

[0050] After testing, the density of the 55mm low-density composite electric heating fiberboard prepared in this example is 550 kg / m3, and its performance index can reach the furniture type used in the dry state in the national standard for medium density fiberboard (GB / T 51718-2009). The performance requirement index of medium density fiberboard, the detection value of its performance index is as follows:

[0051]

Embodiment 3

[0053] The difference from Example 2 is that the heating wire laying device 4 and the heat conducting layer laying device 5 are arranged side by side in the outer shell at intervals. The number of the heating wire laying devices is 4, and along the thickness of the outer shell direction.

[0054] After testing, the density of the 18mm low-density composite electric heating fiberboard prepared in this example is 570 kg / m3, and its performance index can reach the furniture type used in the dry state in the national standard for medium density fiberboard (GB / T 51718-2009). The performance requirement index of medium density fiberboard, the detection value of its performance index is as follows:

[0055]

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com