Method for preparing fiberboard capable of preventing glue spots from being generated on steel belt

A fiberboard and glue spot technology, applied in the field of fiberboard preparation, can solve the problems of steel belt wear, reduced service life of steel belt, damage to steel belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

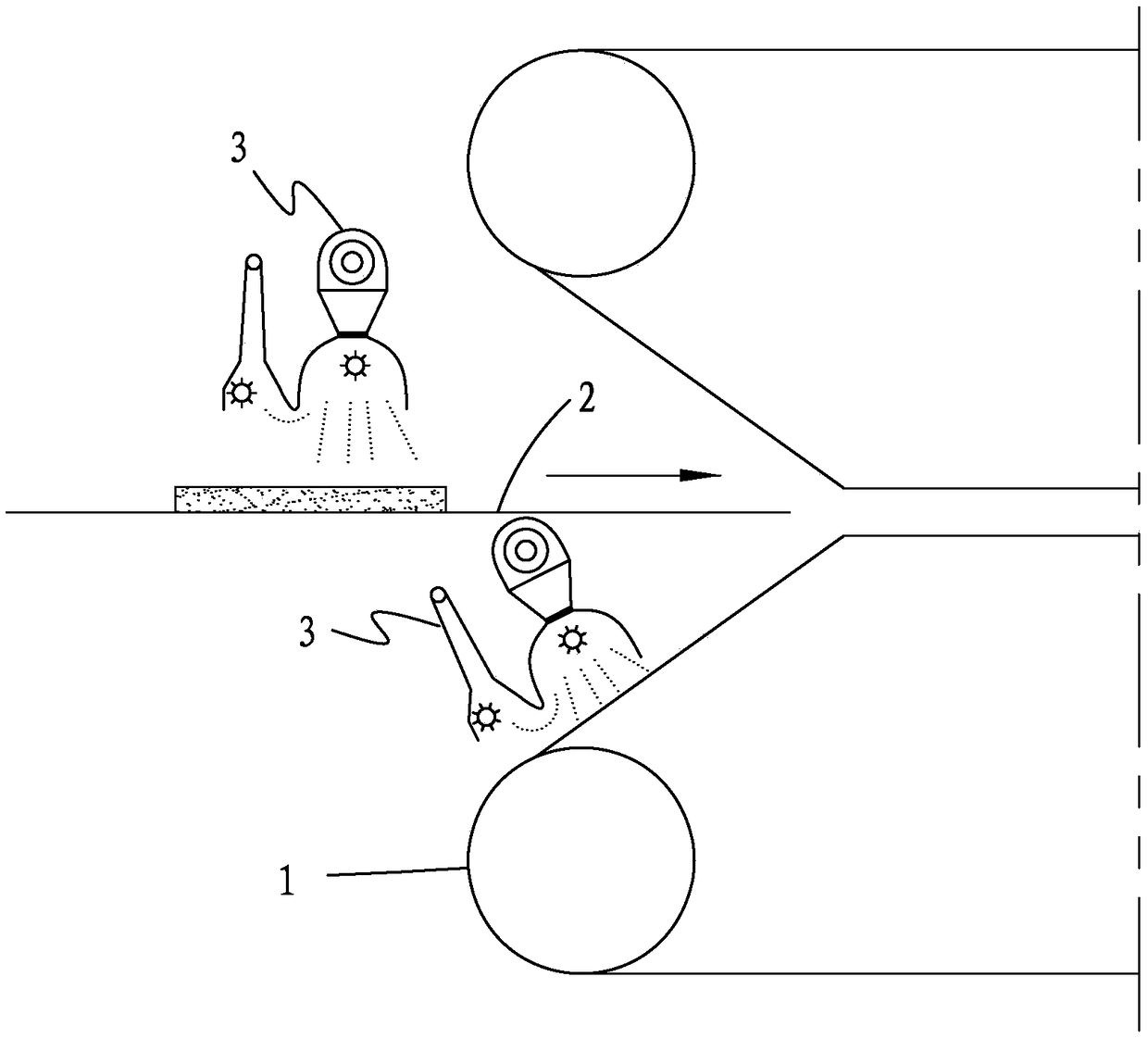

[0023] A method for preparing a fiberboard that avoids glue spots on steel belts, including fiber preparation, fiber sizing, fiber laying, pre-pressing, hot pressing, and raw board treatment. The hot pressing adopts a double-steel belt continuous hot press 1 , the pre-pressed fiber slab is sent into the inlet of the hot press machine with an entry angle by the feed conveyor 2. The steel belt is paved with sanding powder, so that the billets enter the hot press at the entrance. The billet structure from top to bottom is: sanding powder layer, dry fiber layer, and sanding powder layer. Such as figure 1 shown.

[0024] The sanding powder is taken from a coarse sand frame of a fiberboard sanding machine. Before the sanding powder is fed, the particle surface is covered with an adhesive, and the moisture content is 15%-25%. The adhesive is the same as that used for dry fibers.

[0025] The thickness of the sanding powder layer is 0.1-1.0mm.

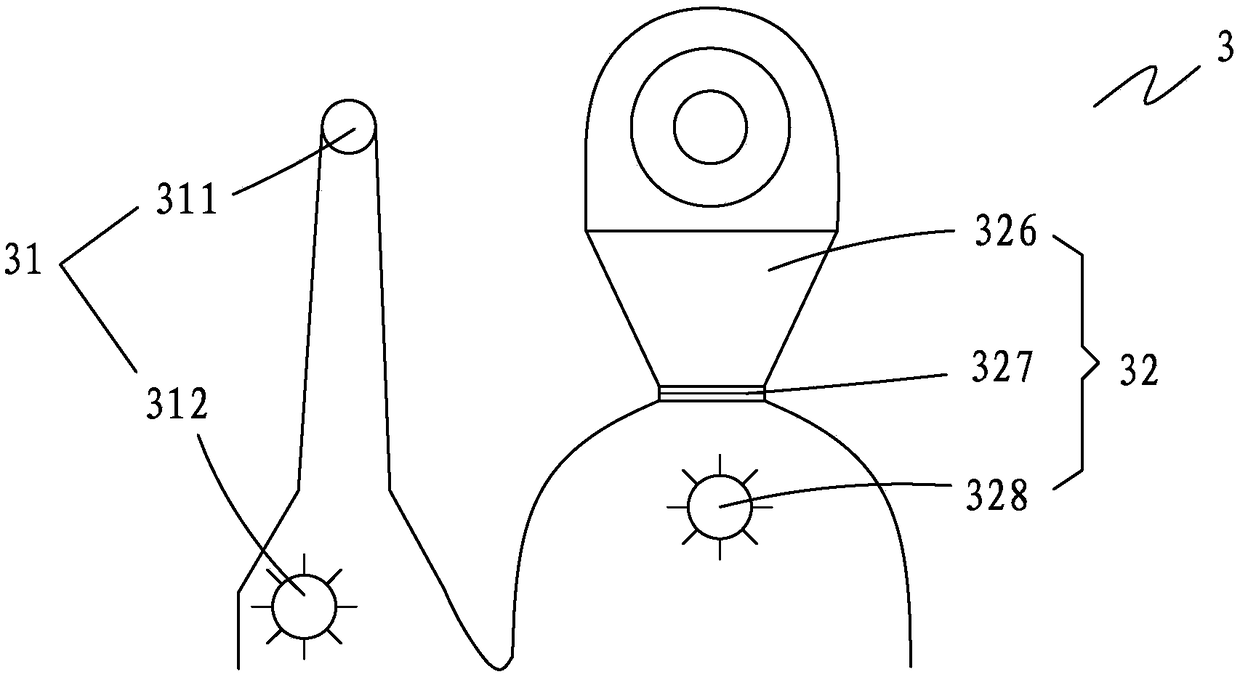

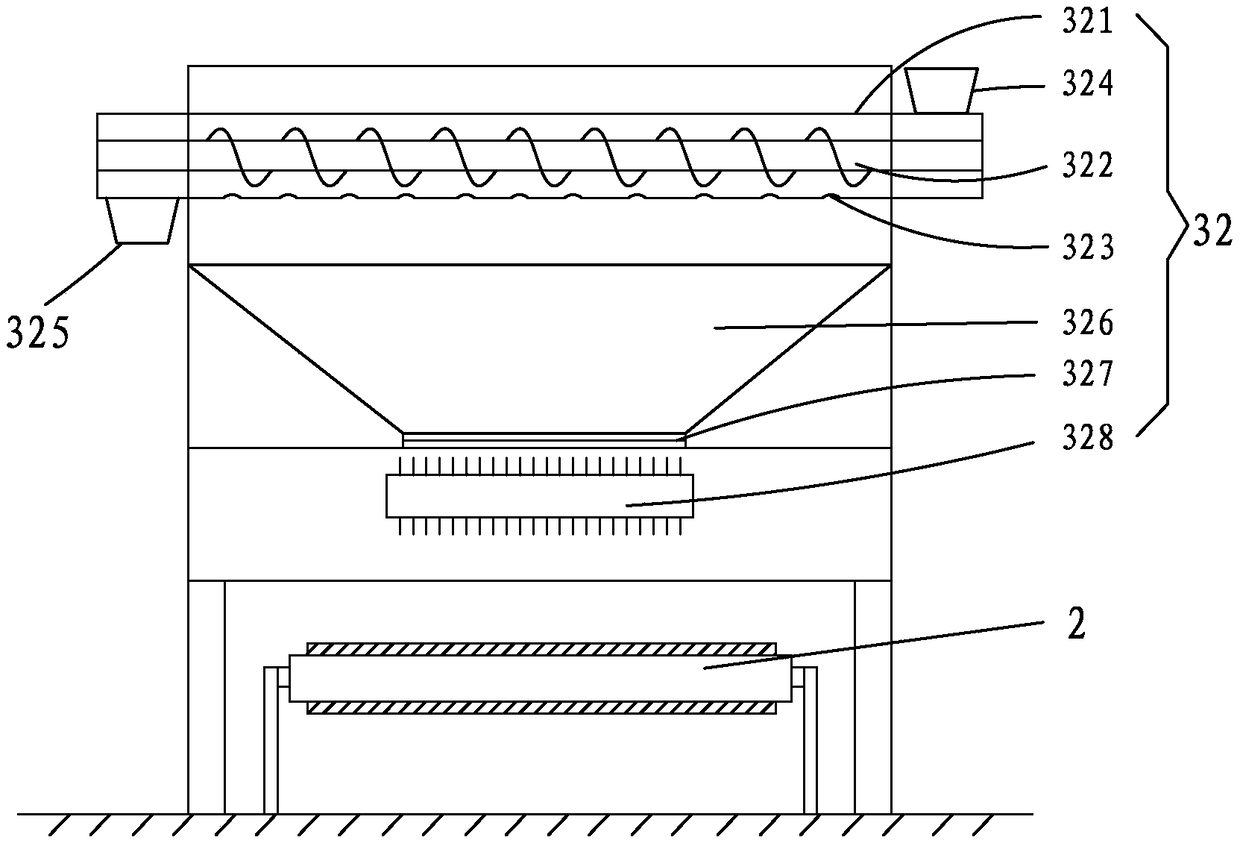

[0026] In order to pave the sanding...

Embodiment 1

[0036] The adhesive is a melamine-modified urea-formaldehyde resin adhesive with a solid content of 48-50% liquid adhesive. The sanding powder: covered urea-formaldehyde adhesive: water weight mixing ratio is: 1000kg: 70kg: 160kg.

[0037] The thickness of each layer of the rough structure is (from top to bottom): sanding powder layer 0.1mm, dry fiber layer 79.2mm, sanding powder layer 0.1mm.

[0038] The process parameters in the hot pressing step are: the hot pressing temperature is 170°C, the closing time of the hot pressing machine is 8 seconds, the hot pressing time is 150 seconds, the hot pressing pressure is 0-3.2MPa, and the hot pressing coefficient is 15 seconds / mm.

[0039] After testing, the density of the 9mm low-density fiberboard prepared in this example is 560 kg / m3, and its performance index can reach the furniture-type medium-density fiberboard used in the dry state in the national standard for medium-density fiberboard (GB / T 11718-2009). The performance re...

Embodiment 2

[0042] The difference from Example 1 is that the weight mixing ratio of sanding powder: covered urea-formaldehyde adhesive: water is: 1000kg: 75kg: 100kg.

[0043] The thickness of each layer of the rough structure is (from top to bottom): sanding powder layer 0.5mm, dry fiber layer 78.2mm, sanding powder layer 0.5mm.

[0044] The process parameters in the hot pressing step are: the hot pressing temperature is 210°C, the closing time of the hot pressing machine is 5.5 seconds, the hot pressing time is 105 seconds, the hot pressing pressure is 0-3.2 MPa, and the hot pressing coefficient is 10.5 seconds / mm.

[0045]After testing, the density of the 9mm low-density fiberboard prepared in this example is 560 kg / m3, and its performance index can reach the furniture-type medium-density fiberboard used in the dry state in the national standard for medium-density fiberboard (GB / T 11718-2009). The performance requirement index of fiberboard, the detection value of its performance ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com