Rapid arc edge printing device and printing method for 3D printer

A 3D printer and printing equipment technology, applied in the field of 3D printing, can solve the problems of affecting the printing effect, slow printing speed, difficult printing, etc., to improve the printing quality of the arc edge, the printing process is accurate and stable, and the printing accuracy is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

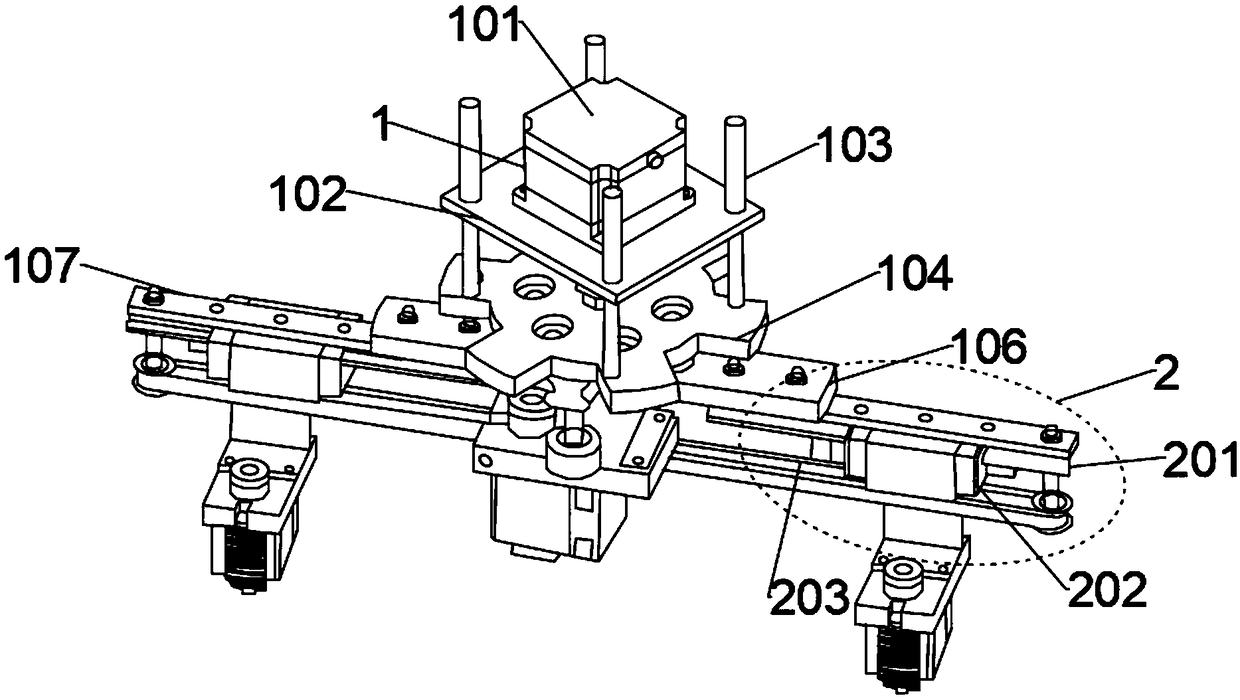

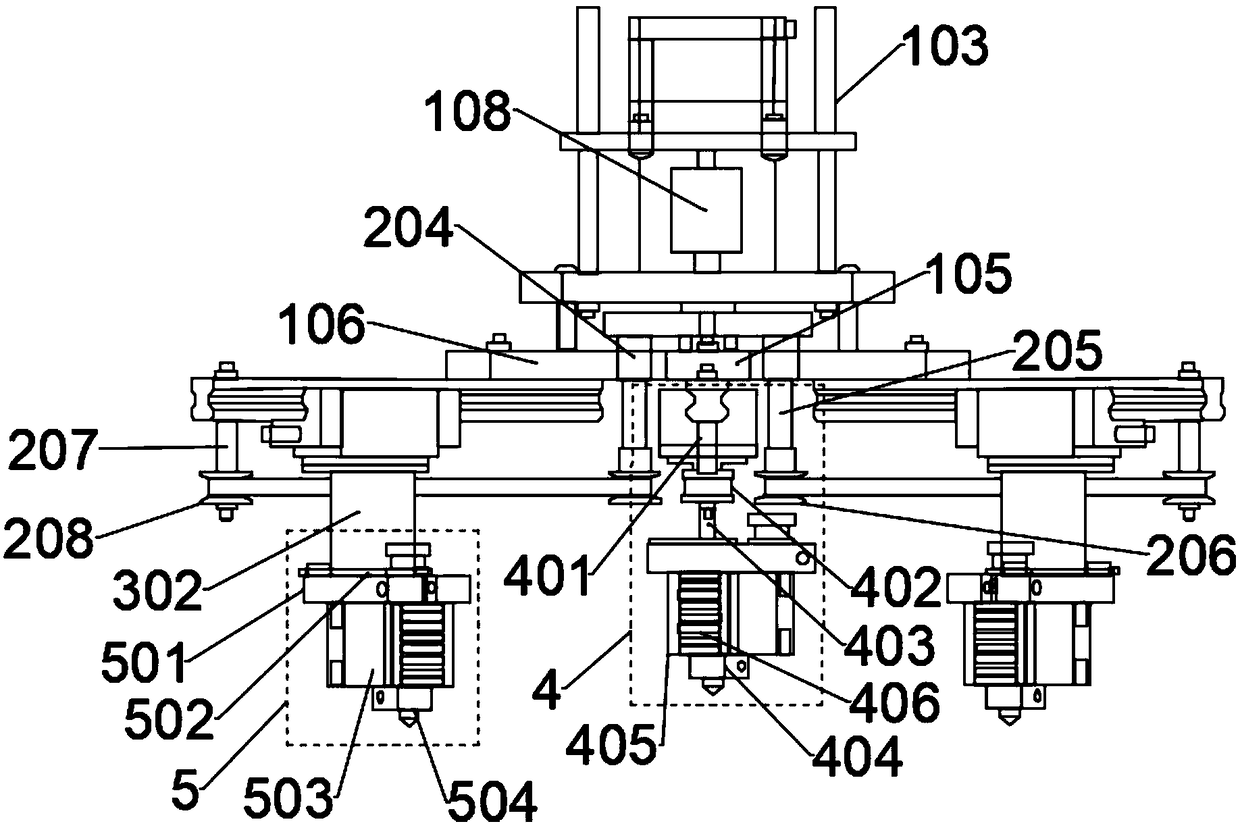

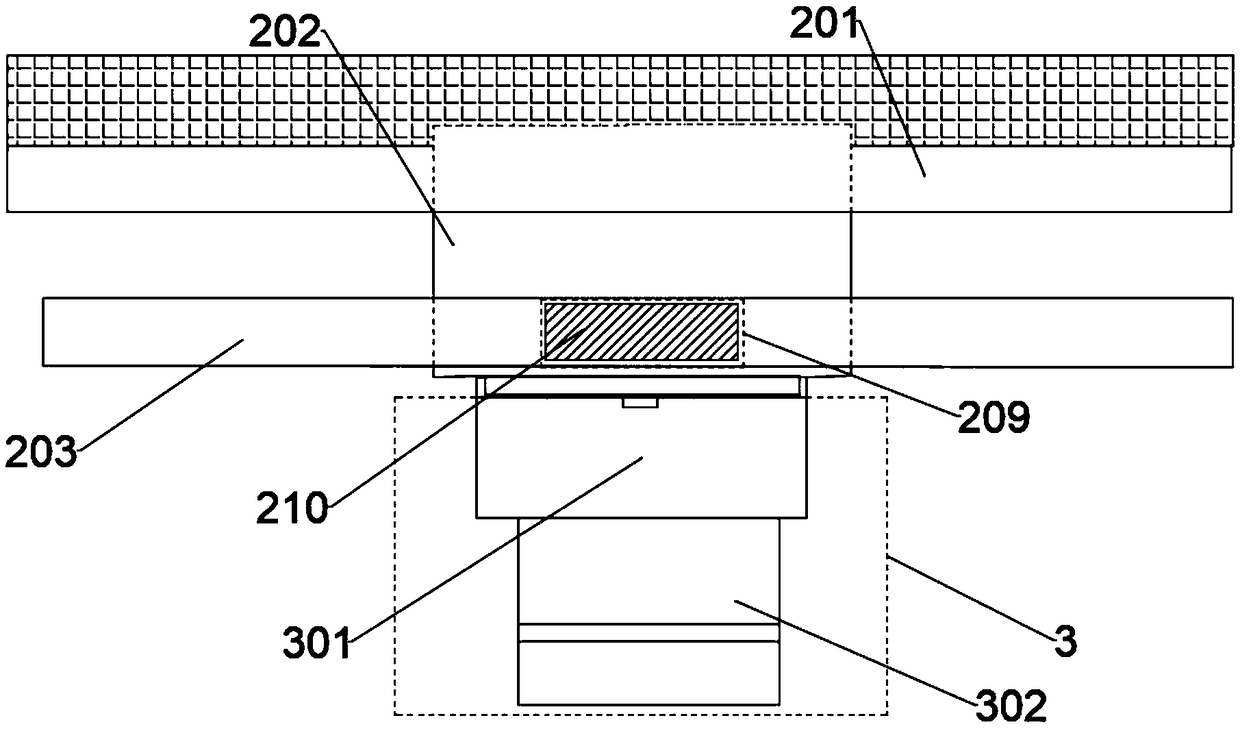

[0043] like figure 1 , figure 2 and image 3 As shown, the present invention provides a technical solution: a rapid arc-edge printing device for a 3D printer, including a fixed-axis rotating device 1, and the left and right sides of the lower end of the fixed-axis rotating device 1 are provided with a spreader adjusting device 2 , the lower end of the boom adjusting device 2 is connected with an arc edge printing head 5, and an arc edge printing head retractable device 3 is arranged between the extending arm adjusting device 2 and the arc edge printing head 5, and two arc edge printing heads are arranged. A printing center main head 4 is arranged at the center of the connecting line of the side printing heads 5 .

[0044] The working mode of the present invention is that the fixed-axis rotating device 1 controls the rotation of the left and right extension arms, the extension arm adjustment device 2 indirectly controls the horizontal position of the arc edge printing head 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com