Manufacturing method of normal temperature cured high-temperature-resistant auxiliary tool material system suitable for autoclave molding process

A technology of autoclave molding and auxiliary tooling, which is applied in the field of composite material manufacturing, which can solve the problems that the surface quality cannot meet the delivery requirements, the pressure cannot be uniformly transmitted, and the manufacturing process is cumbersome, etc., to achieve excellent internal quality and regular surface state , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

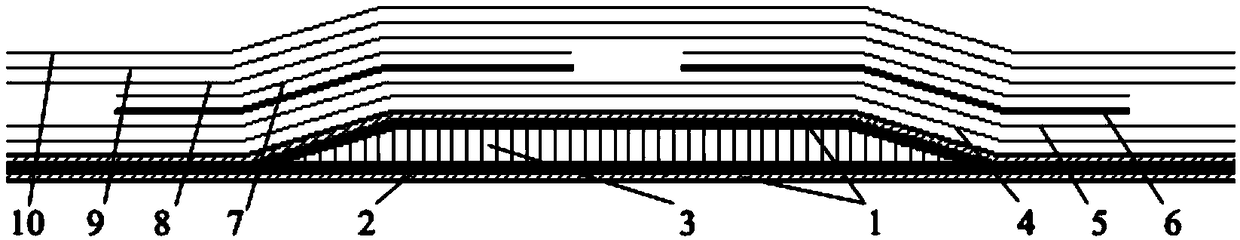

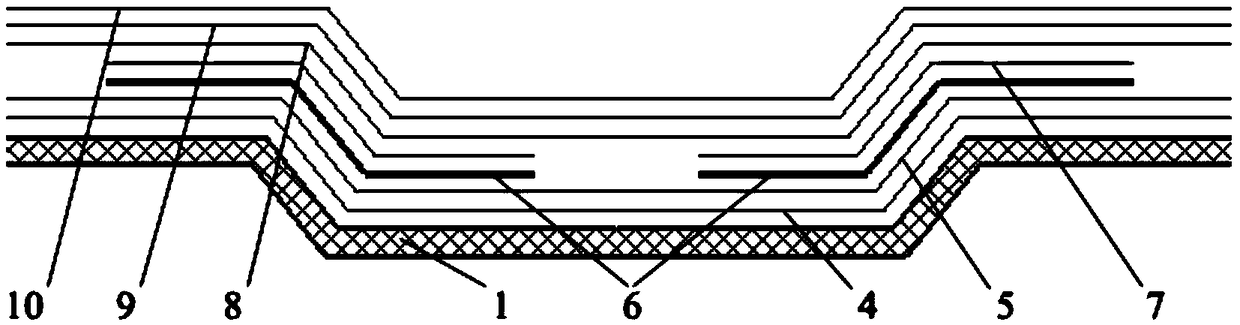

[0023] The content disclosed in the present invention, including the design idea of the components, the selection of materials and the application fields of such material systems should be regarded as the scope of protection of the present invention. In order to further illustrate rather than limit the above-mentioned implementation of the present invention, a combination A typical room temperature curing high temperature resistant auxiliary tooling material system suitable for autoclave molding process and its tooling manufacturing method are further described as an embodiment to the present invention, and the details are as follows:

[0024] A room temperature curing high temperature resistant auxiliary tooling material system suitable for autoclave molding process, the main body of the auxiliary tooling material system is a gradient curing two-component epoxy resin system, according to resin A (E44:AG80=1.5:1 ): curing agent B (T31:IPDA:DDM=2:2:1)=100:35, prepare a gradien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com