EGSB (expanded granular sludge bed) solid-liquid-gas phase separation system

A three-phase separation, solid-liquid separation technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, sedimentation treatment, etc. problems, to achieve the effect of improving the separation efficiency of mud and water, strong anti-corrosion performance and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

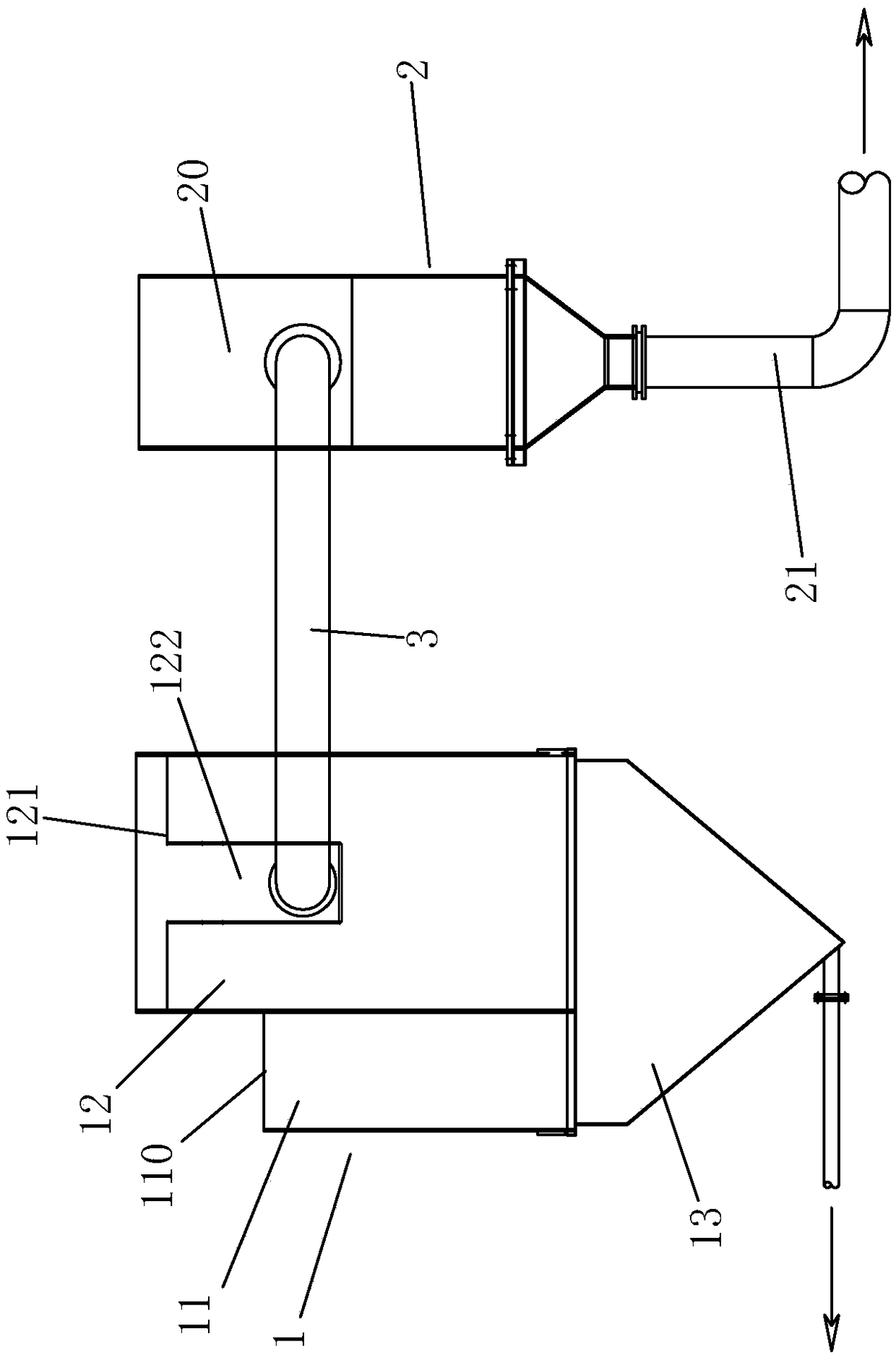

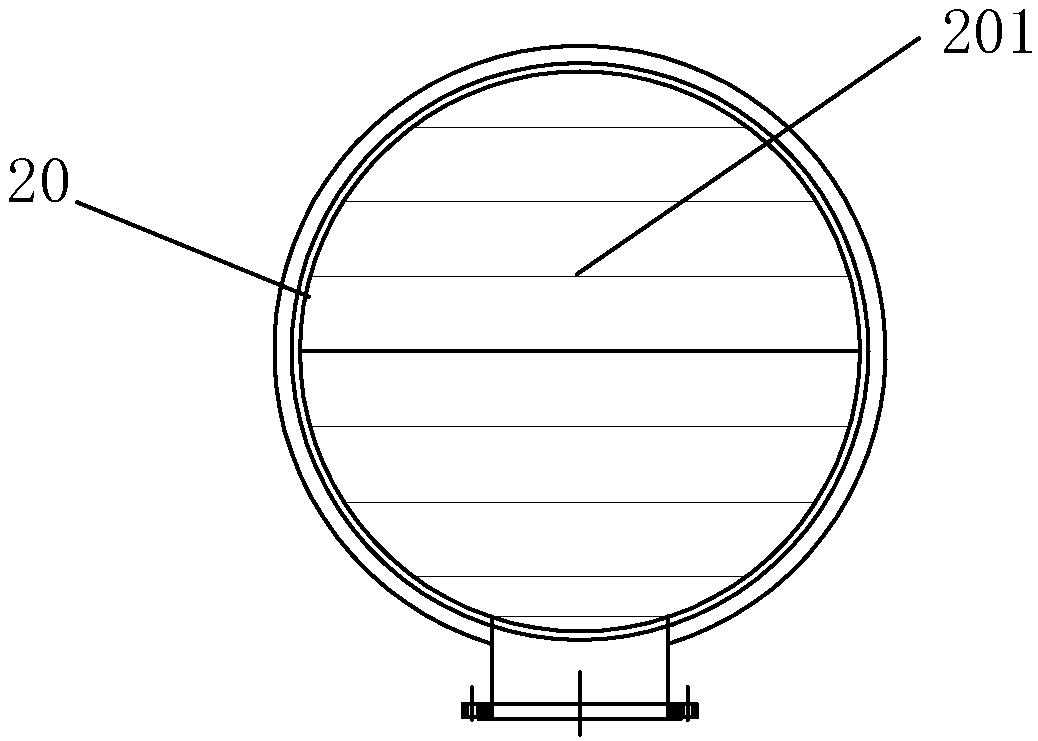

[0025] Such as figure 1 As shown, an EGSB solid-liquid-gas three-phase separation system adopts the principle of forward flow and reverse flow shallow sedimentation for solid-liquid separation of the mixed liquid in the EGSB reactor, and uses the principle of baffle flow for gas-liquid separation, including an interconnected Solid-liquid separation device 1 and a gas-liquid separation device 2, wherein

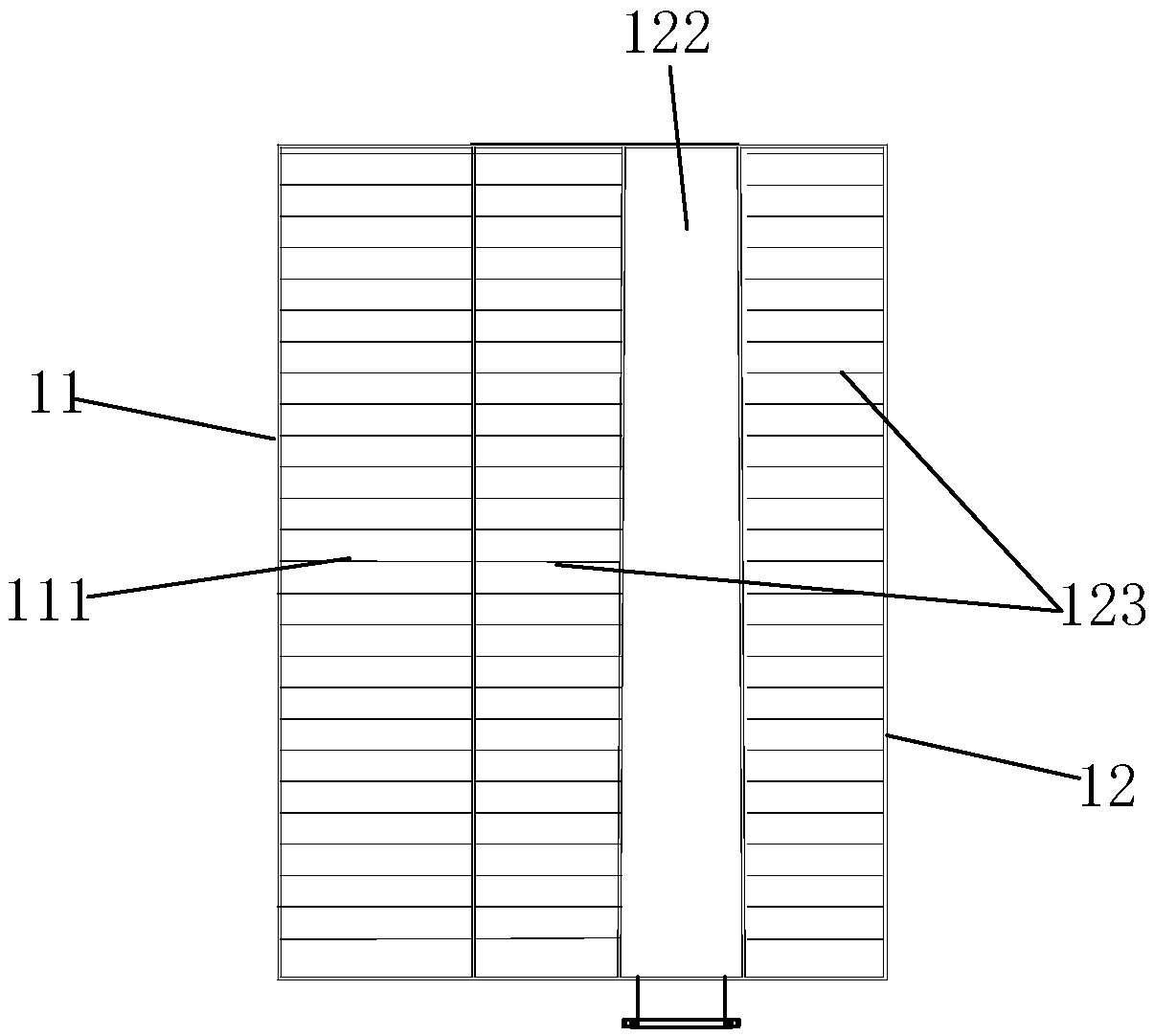

[0026] Such as Figure 1 to Figure 3 As shown, the solid-liquid separation device 1 includes a downstream sedimentation part 11, a countercurrent sedimentation part 12 and a sludge separation assembly 13; the upper end of the downstream sedimentation part 11 has a liquid inlet 110 for the mixed liquid of the EGSB reactor, which There is a first solid-liquid separation inclined plate structure 111...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com