Cleaning device for woven belt

A cleaning device and braided belt technology, which is applied in the processing of textile materials, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of time-consuming and laborious cleaning efficiency, affect sales, reduce the quality of textiles, etc., and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

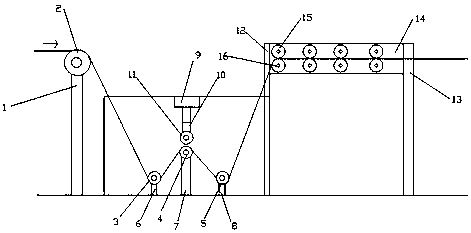

[0025] Such as figure 1 As shown, the technical solution of the present invention is: a cleaning device for a braided belt, including a guiding mechanism, a cleaning mechanism and a drying mechanism arranged in sequence along the conveying direction of the braided belt on the working platform,

[0026] The guide mechanism includes a guide front plate, a guide rear plate 1 and a guide roller 2. The guide front plate and the guide rear plate 1 are arranged parallel to the front and back, and the two ends of the guide roller 2 pass through the first guide shaft and the second guide shaft respectively. The guide shaft is arranged between the guide front plate and the guide rear plate 1, and the joints are provided with guide bearings,

[0027] The cleaning mechanism includes a cleaning box, and the first traction roller 3, the first cleaning roller 4 and the second traction roller 5 are sequentially arranged in the cleaning box along the transmission direction of the braided belt,...

Embodiment 2

[0037] A left limiter and a right limiter are symmetrically sleeved on the guide rod, and the left and right limiters have the same structure, and the left limiter includes a limiter cylinder, and the limiter cylinder The outer edge of one end is provided with a limit edge, and the limit cylinder is set on the guide roller 2, and an adjusting screw hole is arranged on the limit cylinder, and the adjusting bolt passes through the adjusting screw hole, and is supported on the guide roller 2 , the set left and right stoppers play the role of limiting the two sides of the braid passing through the guide roller 2, and improve the guiding effect of the braid.

[0038] The working process of this example: when working, there is a feeding roll in front of the guiding mechanism. The guide roller of the mechanism, the braided belt passes between the two limiters of the guide roller, enters from the belt inlet at one end of the top plate of the cleaning box, and passes through the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com