Mechanical guardrail hoisting device for railway construction

A technology for construction machinery and guard rails, which is applied in the field of recovery devices for railway construction machinery guard rails. It can solve problems such as rebounding of recovery pressure, reduction of connection transmission, and lack of smoothness of runner rotation, etc., to reduce the probability of track loss and simplify the operation. The effect of mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

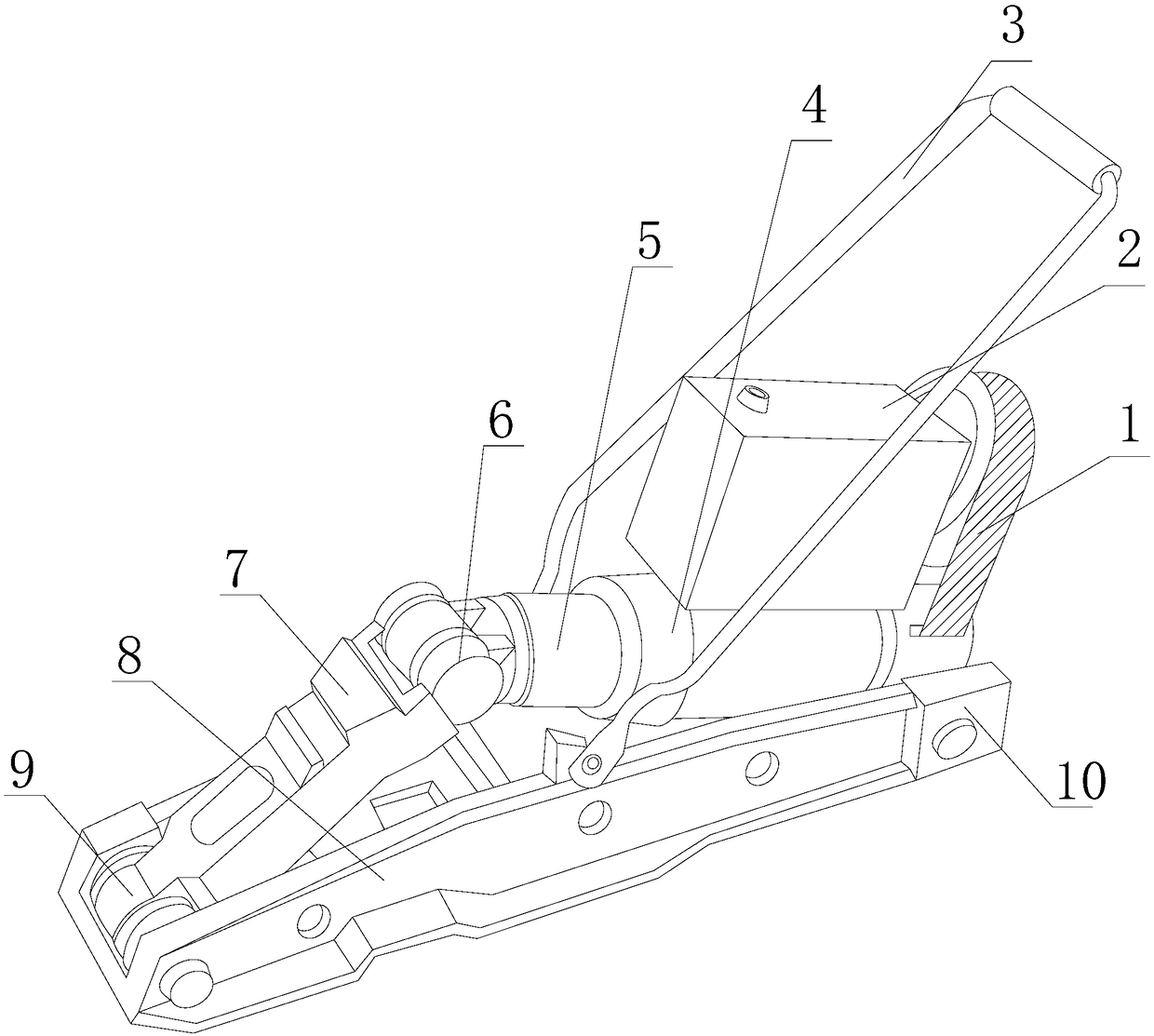

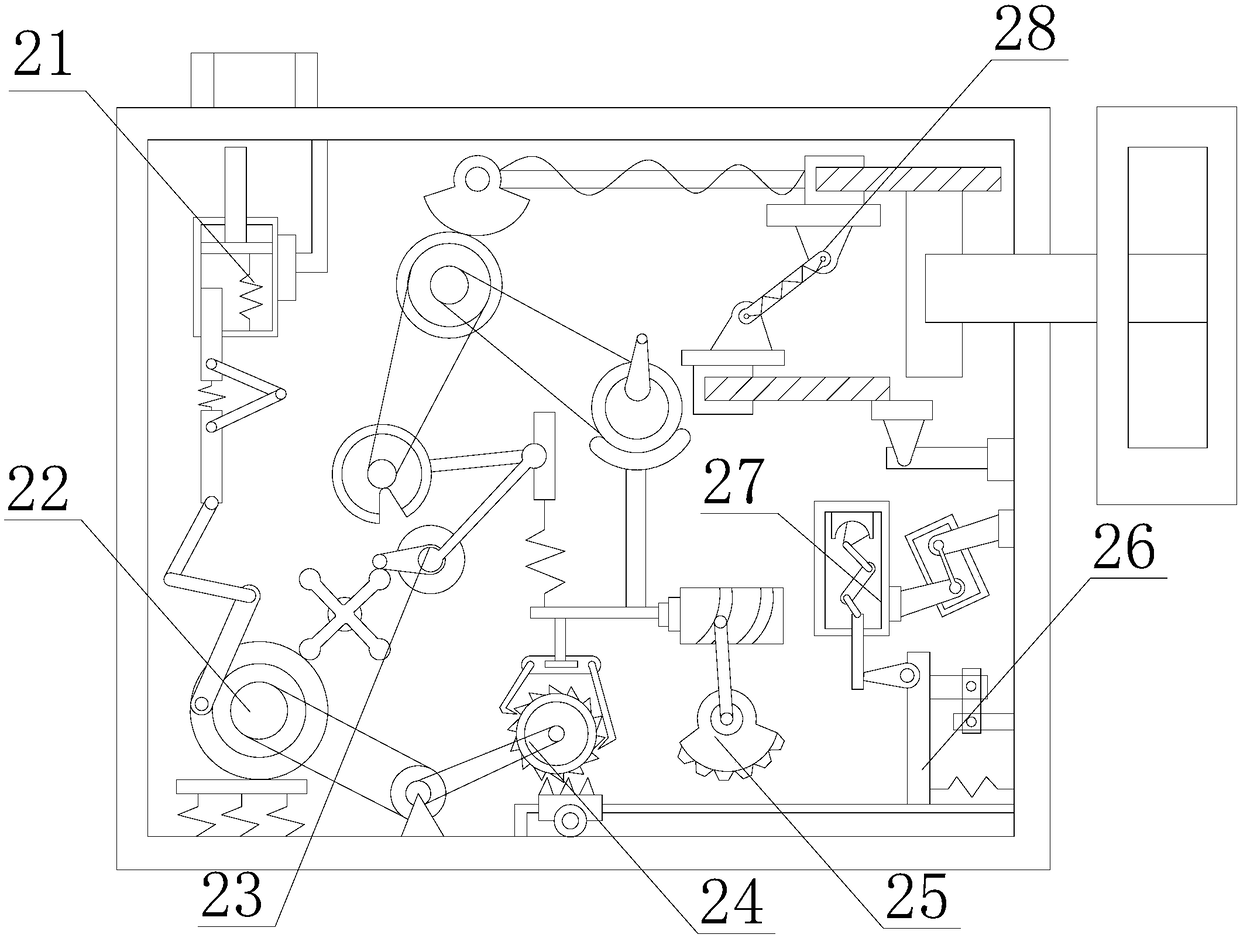

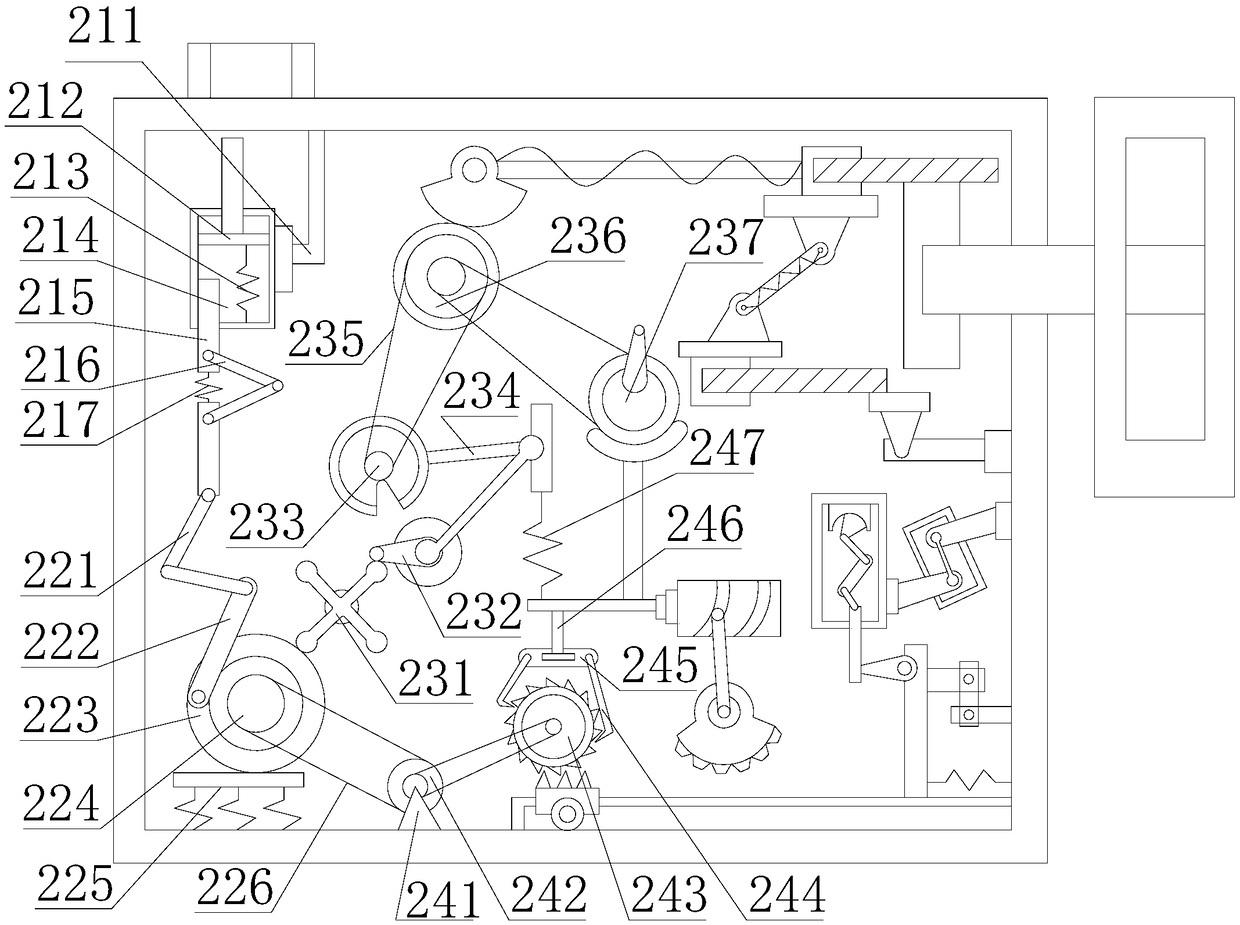

[0025] see Figure 1-Figure 5 , the present invention provides a railway construction machinery guard rail lifting device, its structure includes: shaft wheel conveyor belt 1, wheel speed control box 2, inclined frame handle rod 3, plunger hydraulic cylinder 4, alloy plunger barrel 5, joint roller Wheel 6, guard rail splint 7, lifting groove base 8, hinge roller column 9, rubber fastening block 10, the shaft wheel conveyor belt 1 is inserted on the right side of the runner speed control box 2, and the runner The bottom surface of the speed control box 2 is closely attached to the top surface of the plunger hydraulic cylinder 4. The alloy plunger barrel 5 is inserted on the left side of the plunger hydraulic cylinder 4 and the axes are collinear. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com