The method of step-by-step pouring hopper pouring concrete for large-graded aggregate concrete

A technology for pouring concrete and concrete, which is applied in the processing of building materials, construction, building structure, etc. Reasonable design, simple force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

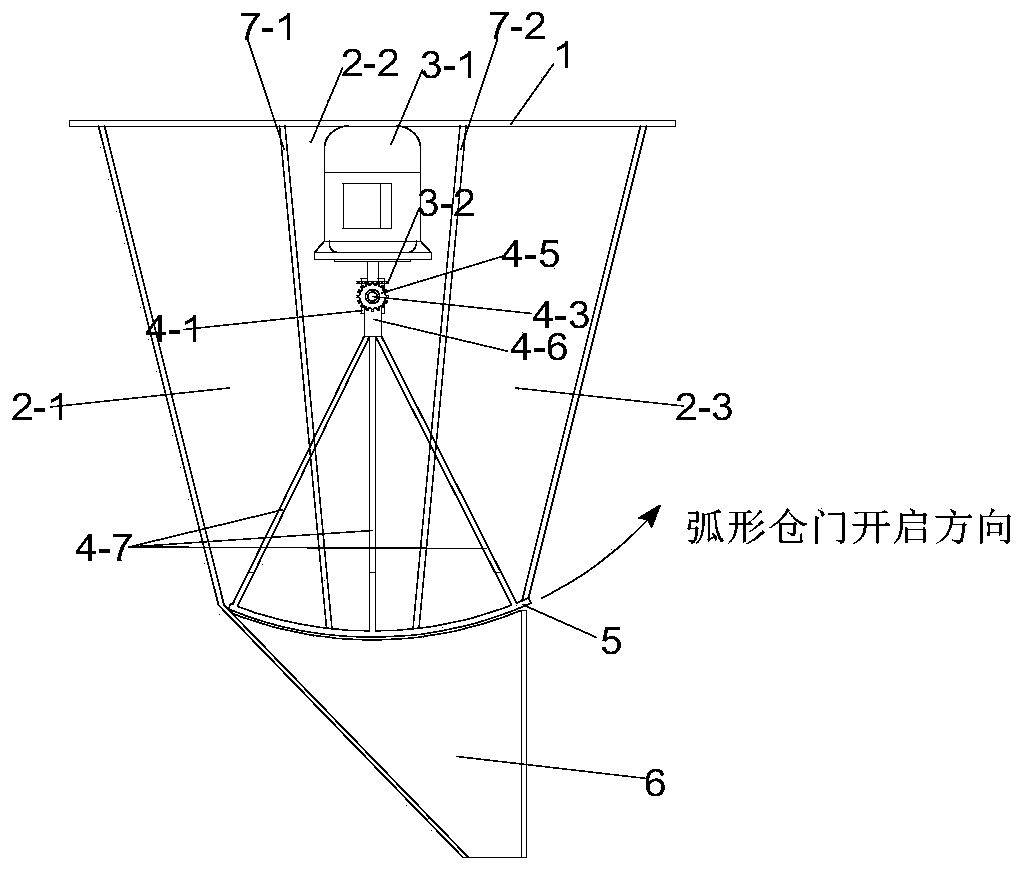

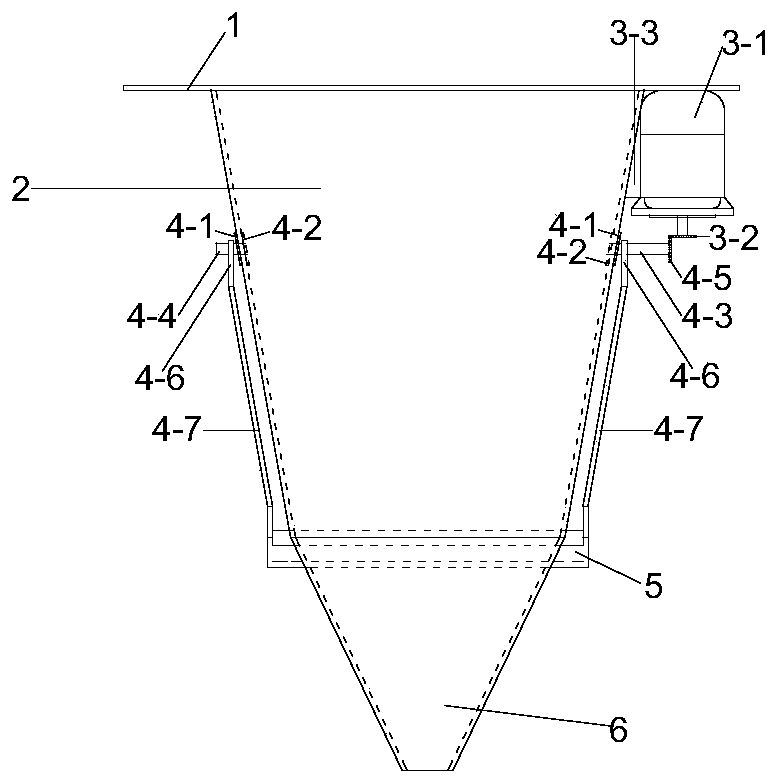

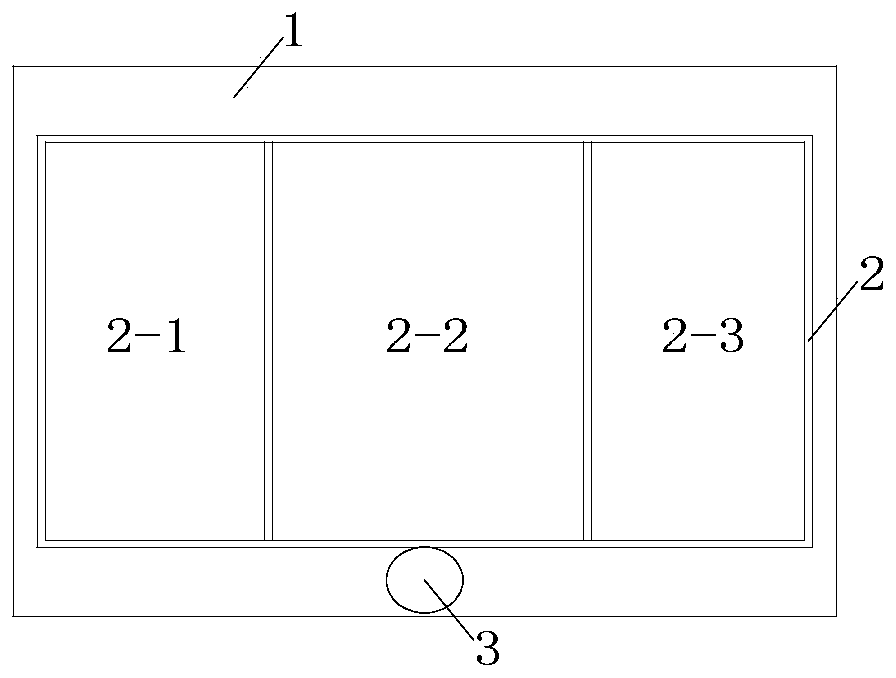

[0025] Such as figure 1 As shown, a step-by-step pouring hopper for large-graded aggregate concrete includes a support plate 1 , a main bucket 2 , an arc gate 5 and a distribution nozzle 6 .

[0026] The bracket plate 1 is fixedly installed on the main bucket 2 to reinforce the structure of the main bucket 2 . The main bucket 2 is a cylinder with upper and lower openings. The outlet below the main bucket 2 is provided with an arc-shaped gate 5, which can block the opening below the main bucket 2, and the bottom of the main bucket 2 is fixedly connected with a distribution nozzle 6, and the lower opening of the main bucket 2 communicates with the distribution nozzle 6. The shaped gate 5 can slide between the slots provided between the distribution nozzle 6 and the main bucket 2 . Along the opening direction of the arc gate 5, the main bucket 2 is sequentially provided with a first partition board 7-1 and a second partition board 7-2 to divide the main bucket 2 into a first ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com