An automatic rotating device for the polished rod of the pumping unit

A technology for automatic rotation and pumping wells, applied to drill pipes, drilling equipment, drill pipes, etc., can solve problems such as bulky, complex structures, and difficult installation, and achieve the effects of improving production efficiency, simplifying structures, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

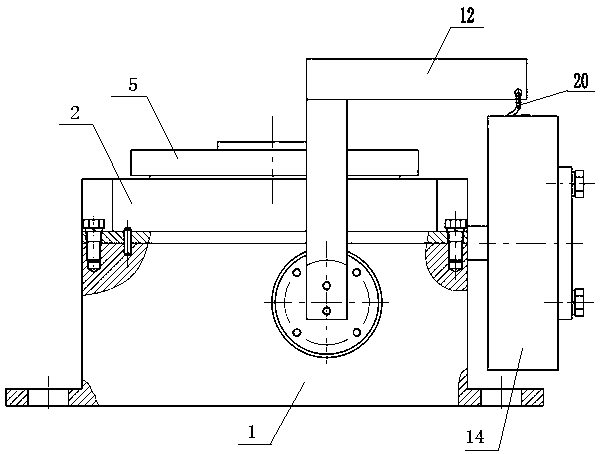

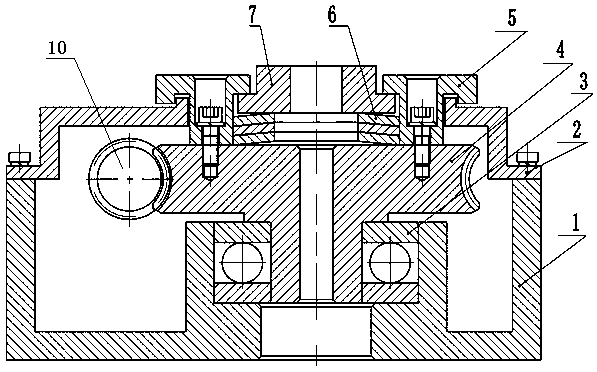

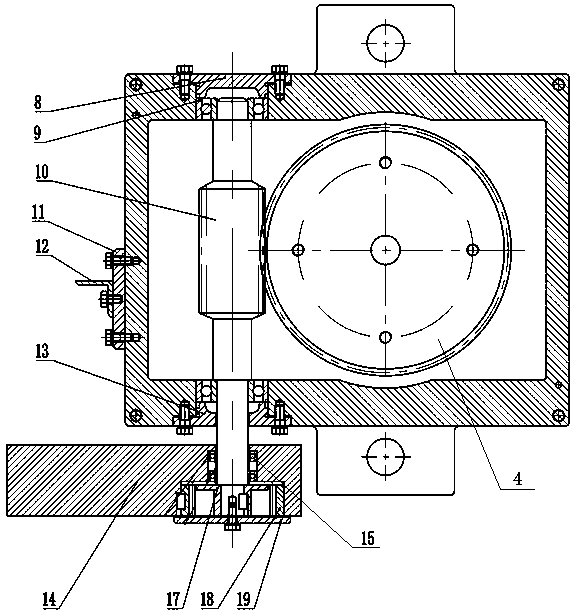

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

[0025] to combine Figure 1-Figure 5 As shown, the automatic rotation device for the well polished rod of the pumping unit includes a box body, a transmission mechanism, and a weight assembly. The weight assembly includes a fan-shaped weight 14, a tension spring 20, and a tension spring support 12. The fan-shaped metal block of mass, the fan-shaped weight 14 is outside the box body, and the weight 14 is connected with the tension spring support 12 through the tension spring 20; The hammer 14 is connected with the worm 10 through the overrunning clutch 23, the weight 14 can swing around the direction of the worm shaft, the worm 10 and the worm gear 4 are arranged inside the box, the two ends of the worm 10 are connected with the box through bearings, the worm 10 cooperates with the worm gear 4 . The weight 14 rotates by the inertial force of the up and down movement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com