Construction method for disassembling of shield tunneling machine in narrow and small space

A narrow space and construction method technology, applied in the direction of earth drilling, mining equipment, underground transportation, etc., can solve the problem that the shield cannot be smoothly received by the shield tail in stages, and achieve the effect of dismantling and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

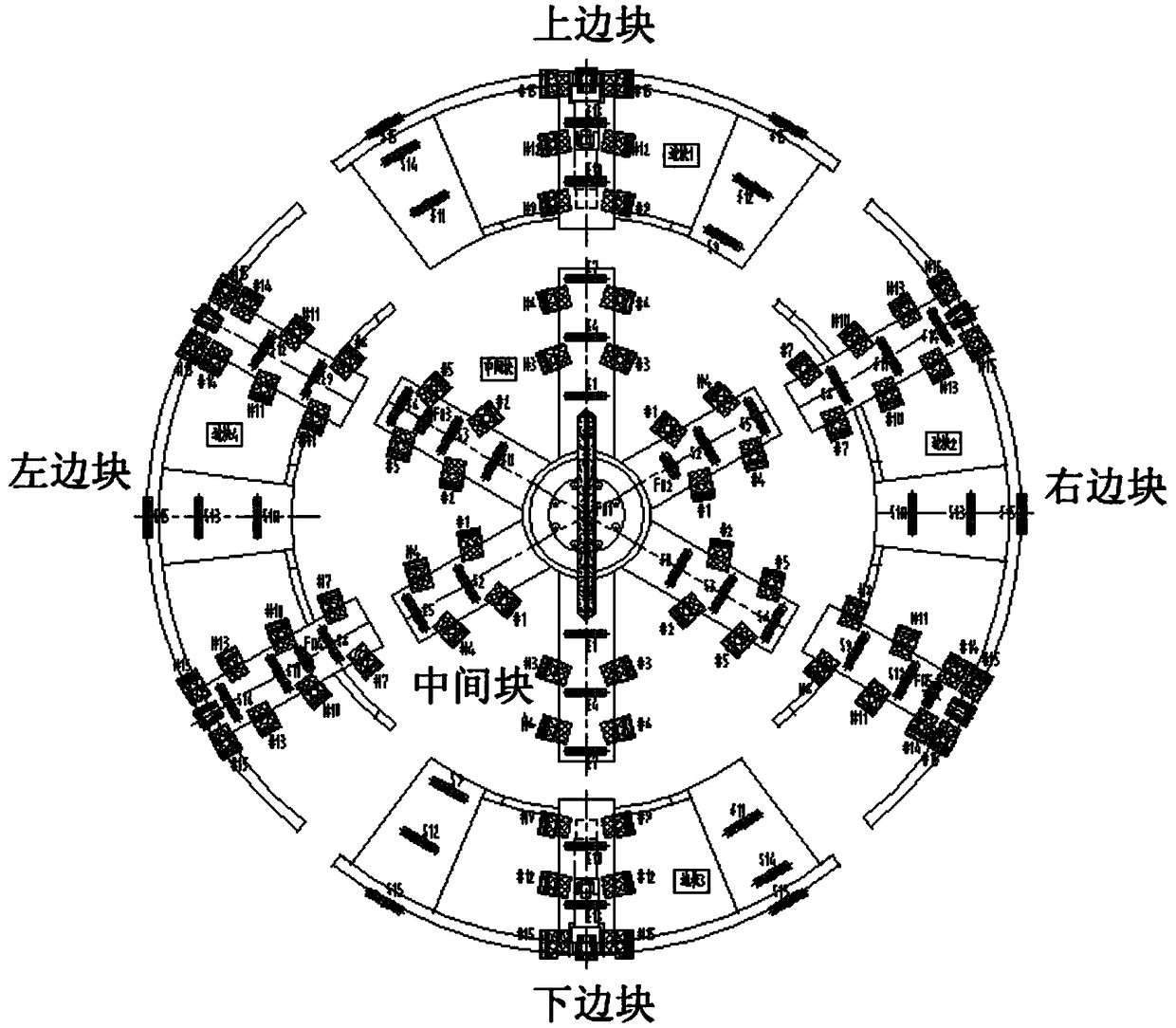

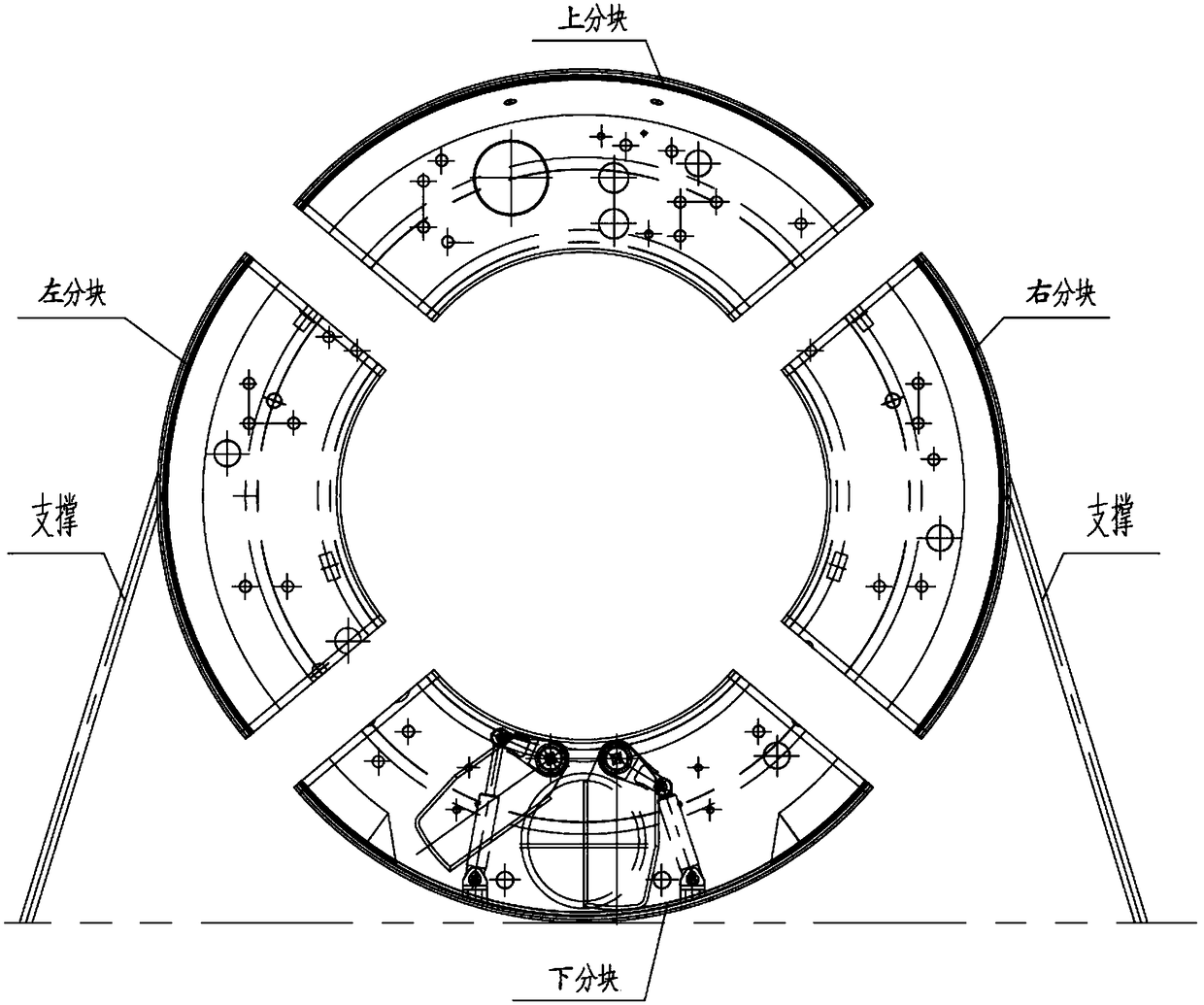

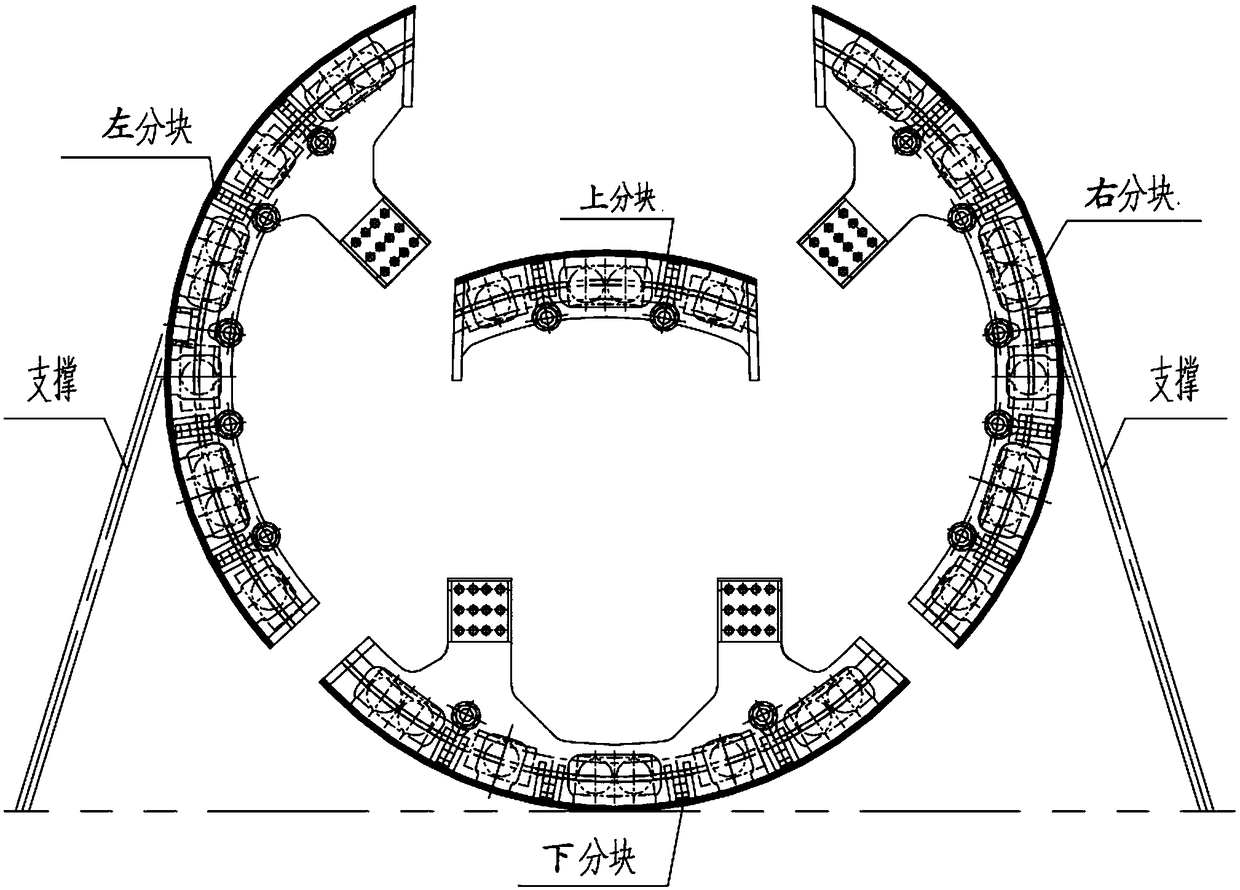

[0074] Such as Figure 1-3 As shown, a construction method for dismantling a shield machine in a small space includes the following steps:

[0075] Step 1: In order to facilitate the disassembly of the shield body, the shield body is designed as an assembled shield body. The cutter head of the shield machine is welded with 4 side blocks and 1 middle block by welding; the front shield of the shield machine is welded The outer surface of the four blocks of the front shield is affixed, and the inner side is bolted between the front shield block and the front shield block with high-strength bolts; the middle shield of the shield machine uses welding to weld the four parts of the middle shield The outer surface of the block is fixed, and the inner side is bolted between the middle shield block and the middle shield block with high-strength bolts; the tail shield of the shield machine is fixed in blocks by welding;

[0076] Step 2: Tunneling, arrival, and reception of the shield ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com