Multi-row drill automatic feeding and discharging device

An automatic loading and unloading and positioning device technology, which is applied in metal processing and other directions, can solve problems such as high labor intensity, and achieve the effect of solving high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

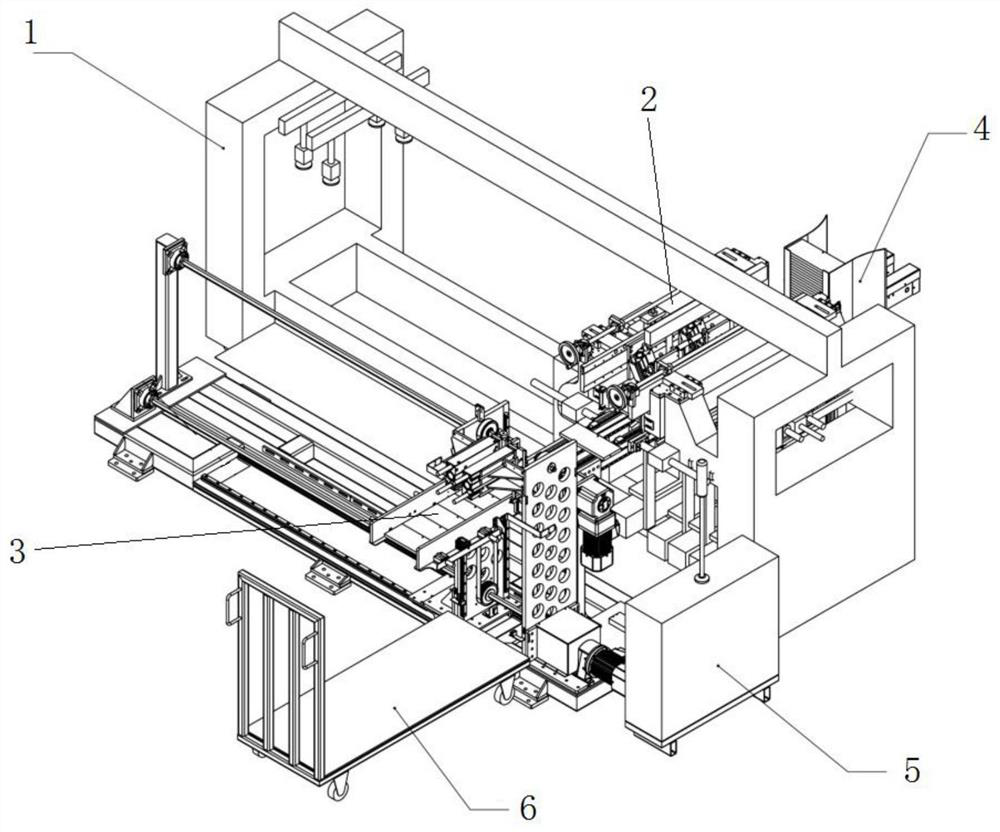

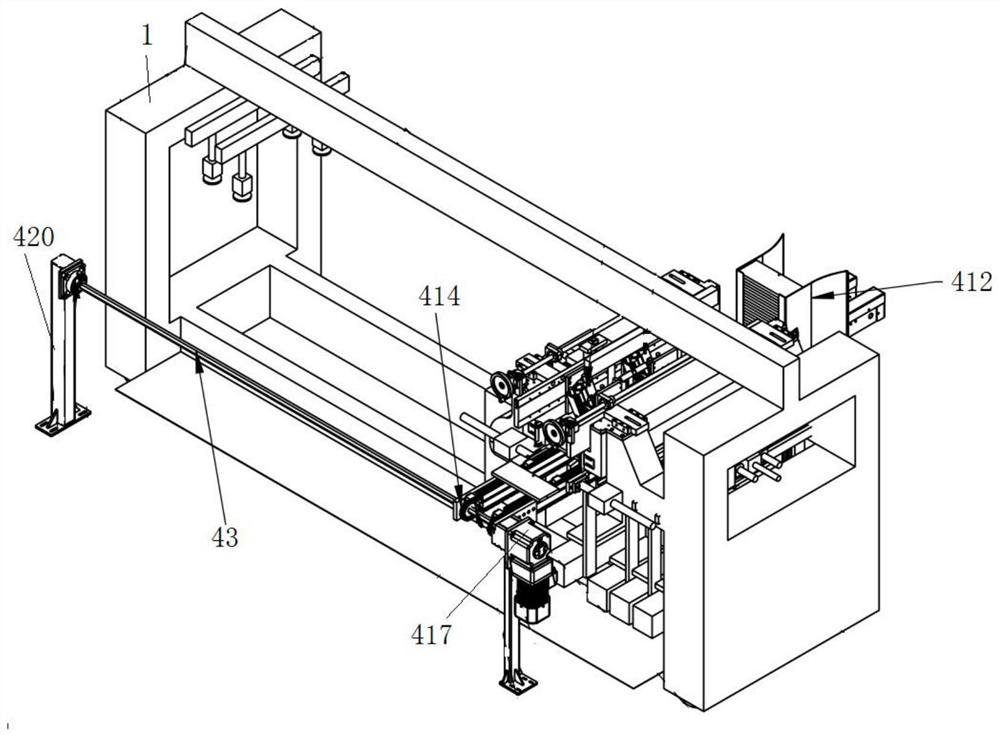

[0036] refer to Figure 2-5 , the sheet conveying assembly 4 spans above the bottom of the multi-row drill body 1, and consists of a left sheet conveying chain 41, a right sheet conveying chain 42 and a left sheet conveying chain 41, right The sheet material conveying chain 42 is composed of a polygonal shaft 43, and the width between the left sheet conveying chain 41 and the right sheet conveying chain 42 can be connected horizontally and telescopically, and the sheet material is conveyed longitudinally. The pressing plate assembly 2 is arranged above the sheet material conveying assembly 4 and is tightly connected with the multi-row drill body 1; Move the plate to the moving plate car 6.

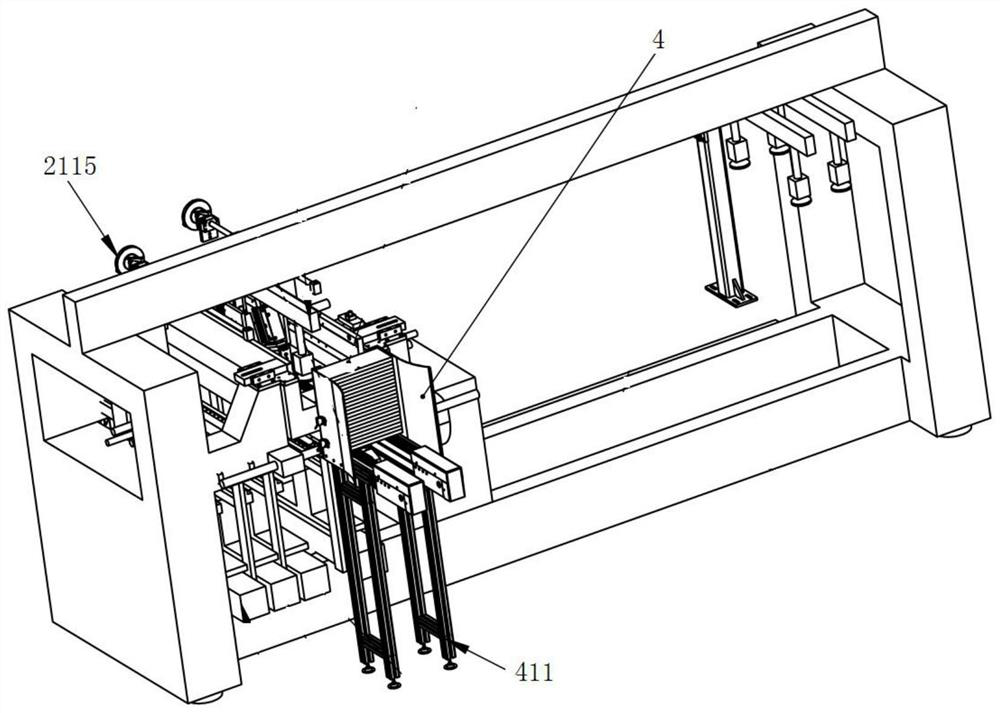

[0037] The left sheet material conveying chain 41 includes a support frame 411, a left storage plate box cover 412, a left chain groove plate 413, a chain 414, a left driven sprocket set 415, a left driving sprocket set 416, a drive motor 417 and a reversing Gear box, motor support feet ...

Embodiment 2

[0045] refer to Figure 6-7 , the platen assembly 2 includes two positioning devices 21 , the positioning devices 21 are installed on the frame of the multi-row drill body 1 , respectively corresponding to the upper side of the left sheet conveying chain 41 and the right sheet conveying chain 42 . It is used to press the sheets on the left sheet conveying chain 41 and the right sheet conveying chain 42 .

[0046] The positioning device 21 includes a device base plate 211, a drill body connecting plate 212 and a position adjustment mechanism; the position adjustment mechanism is connected with the device base plate 211, and the position adjustment mechanism is connected with a connecting plate 1 213 and a connecting plate 2 214; the first connecting plate 213 is installed on the There is a cylinder 1 215, a connecting plate 214 is installed with a cylinder 2 216; a distance adjusting rod 217 is connected between the connecting plate 1 213 and the connecting plate 2 214; an angl...

Embodiment 3

[0050] refer to Figure 8-11 , the material receiving assembly 3 includes a horizontal connecting plate mechanism and a longitudinal moving plate mechanism, and the horizontal connecting plate mechanism includes an L-shaped left moving plate 31, an L-shaped right moving plate 32, a connecting plate 33, a cylinder 34, a gear rod cylinder 35, Longitudinal moving mounting plate 37 and conveying plate 38; L-shaped left-moving plate 31 and L-shaped right-moving plate 32 are provided with two parallel sliding rails 39 on both sides of the inner side, the sliding rails 39 are perpendicular to the ground, and the L-shaped left-moving plate 31 . The inner side of the L-shaped right shift plate 32 has a moving slide plate 310 slidably connected to the slide rail 39 , and the moving slide plate 310 slides up and down along the slide rail 39 . The lower edge of the inner side of the moving slide 310 protrudes to form a supporting edge, and the upper end of the supporting edge is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com