Commercial kitchen waste treatment system

A food waste and treatment system technology, applied in grain treatment, chemical instruments and methods, solid waste removal, etc., can solve the problems of reduced utilization rate of resources, slow processing speed, poor continuous operation performance, etc. Transportation and operation problems, reduction of law enforcement costs, and reduction of collection and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

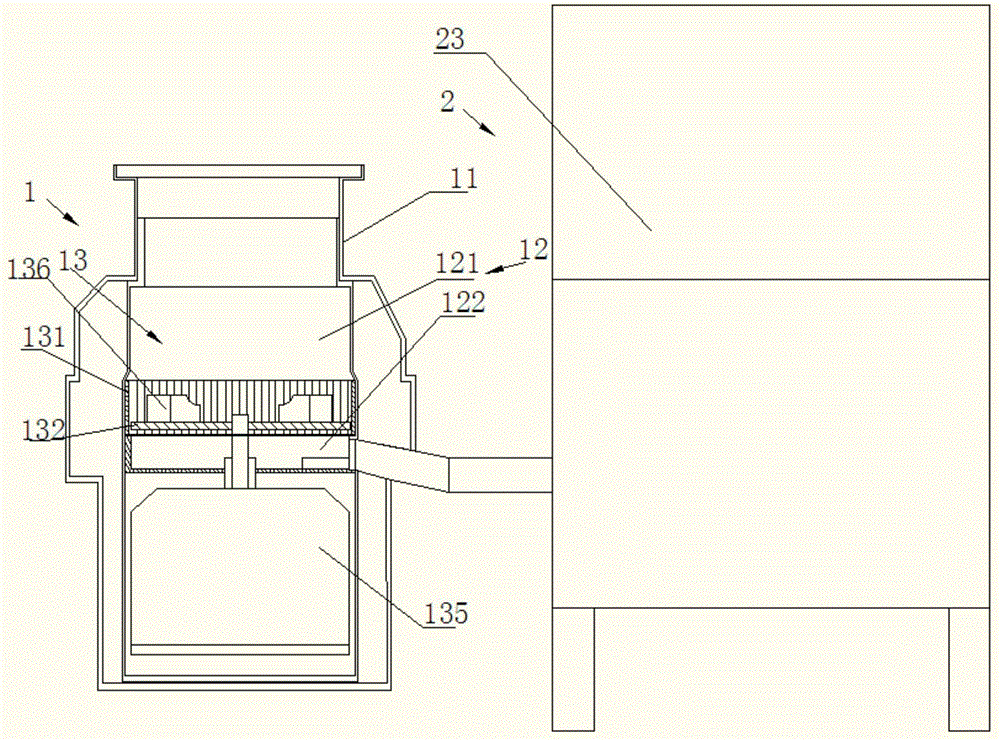

[0025] Such as figure 1 As shown, the commercial food waste treatment system includes a grinding part 1 for grinding and crushing the food waste, and a dehydration part 2 for dehydrating and drying the food waste after the grinding part is ground and crushed. The grinding unit 1 is installed below the pool, and the dehydration unit 2 is located on the side of the grinding unit 1 .

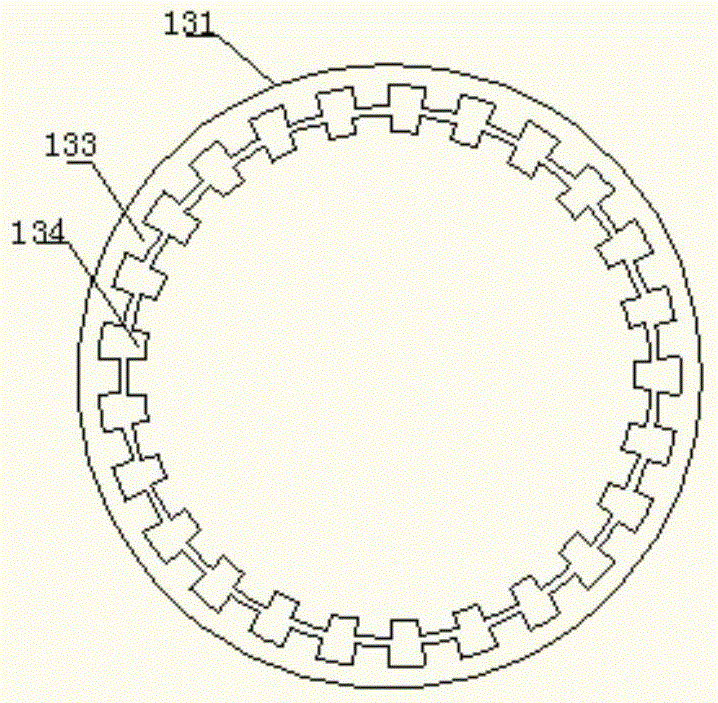

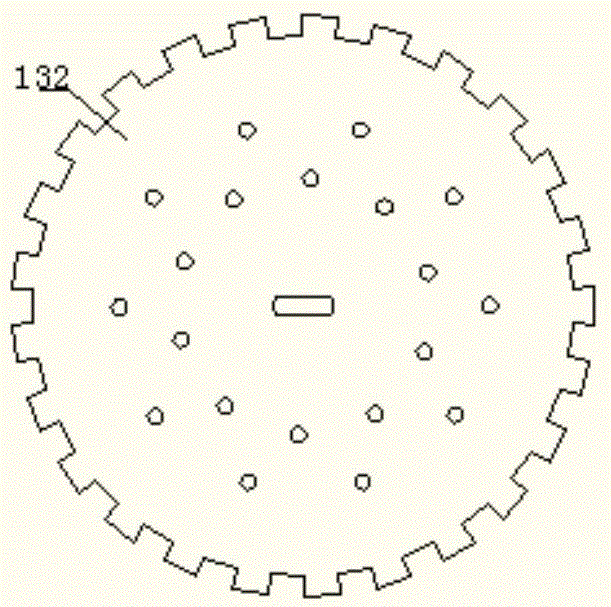

[0026] Such as figure 2 , 3 , 4, the grinding part 1 includes a grinding shell 11, a grinding chamber 12 installed in the grinding shell 11, a grinding chamber 12 installed in the grinding chamber 12 and dividing the grinding chamber 12 into an upper grinding chamber 121 and a lower grinding chamber 122 Component 13, the grinding motor 14 installed in the grinding housing 12 and below the lower grinding chamber 122. The rotating shaft of the grinding motor 14 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com