Tunnel structure

A technology of tunnel and structure, which is applied in the field of tunnels, can solve the problems of accelerating the connection failure of inverted arch prefabricated blocks, the stress of a single inverted arch prefabricated block, and the degree of aggravating the degree of road surface depression, so as to reduce the probability of road surface water leakage and install The effect of shortening time and eliminating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

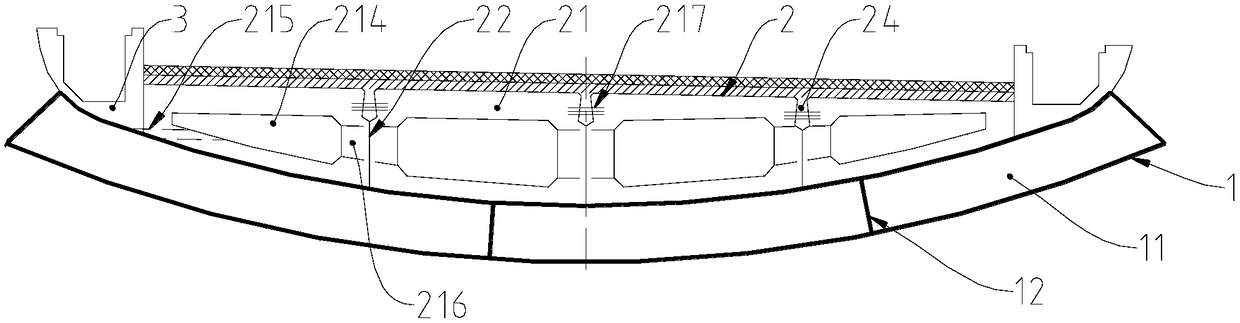

[0036] Such as figure 1 As shown, the tunnel structure, including the inverted arch and the inverted arch backfill layer;

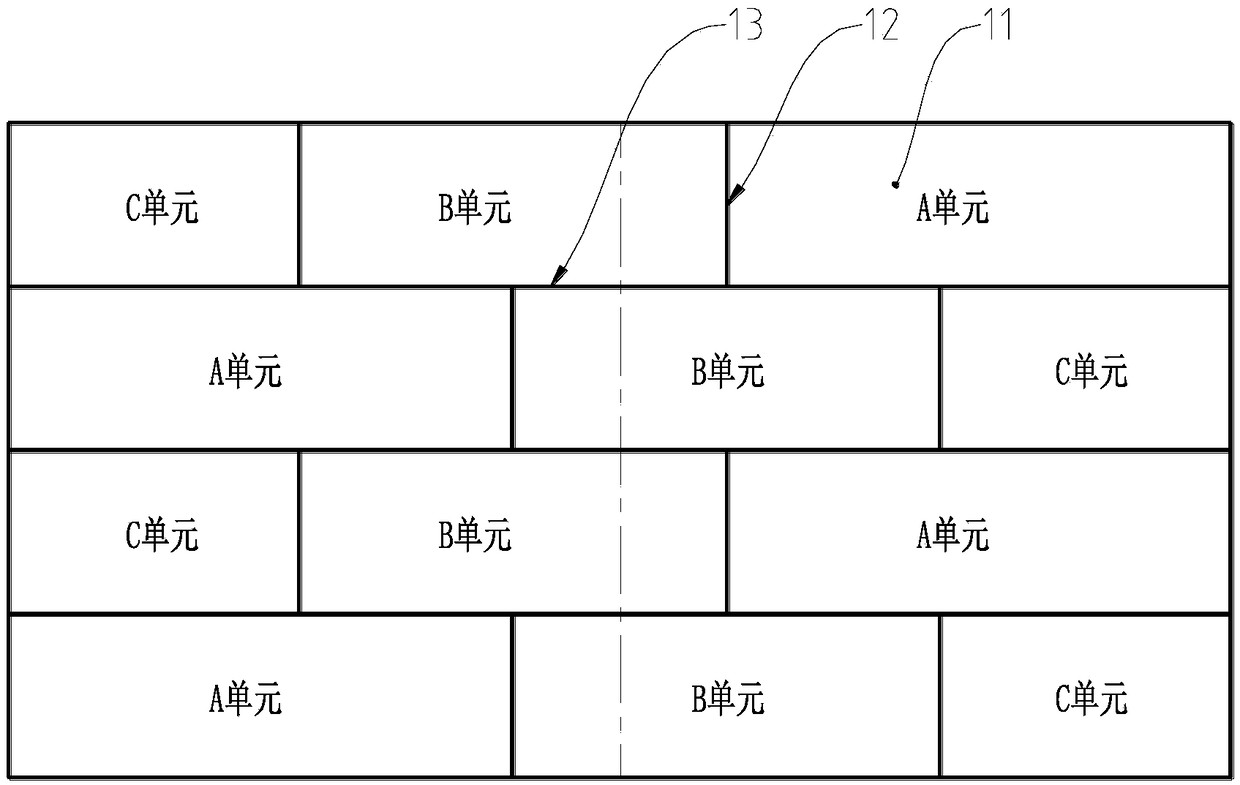

[0037] The inverted arch is spliced by a group of inverted arch units 1 along the longitudinal direction of the tunnel, and each inverted arch unit 1 is spliced by a group of inverted arch prefabricated blocks 11 along the tunnel ring direction; the combination of two adjacent inverted arch units 1 The seams between the surfaces form the invert arch circumferential seam 13, and the seams between the joint surfaces of two adjacent inverted arch prefabricated blocks 11 in each invert arch unit 1 form the invert arch longitudinal seam 12;

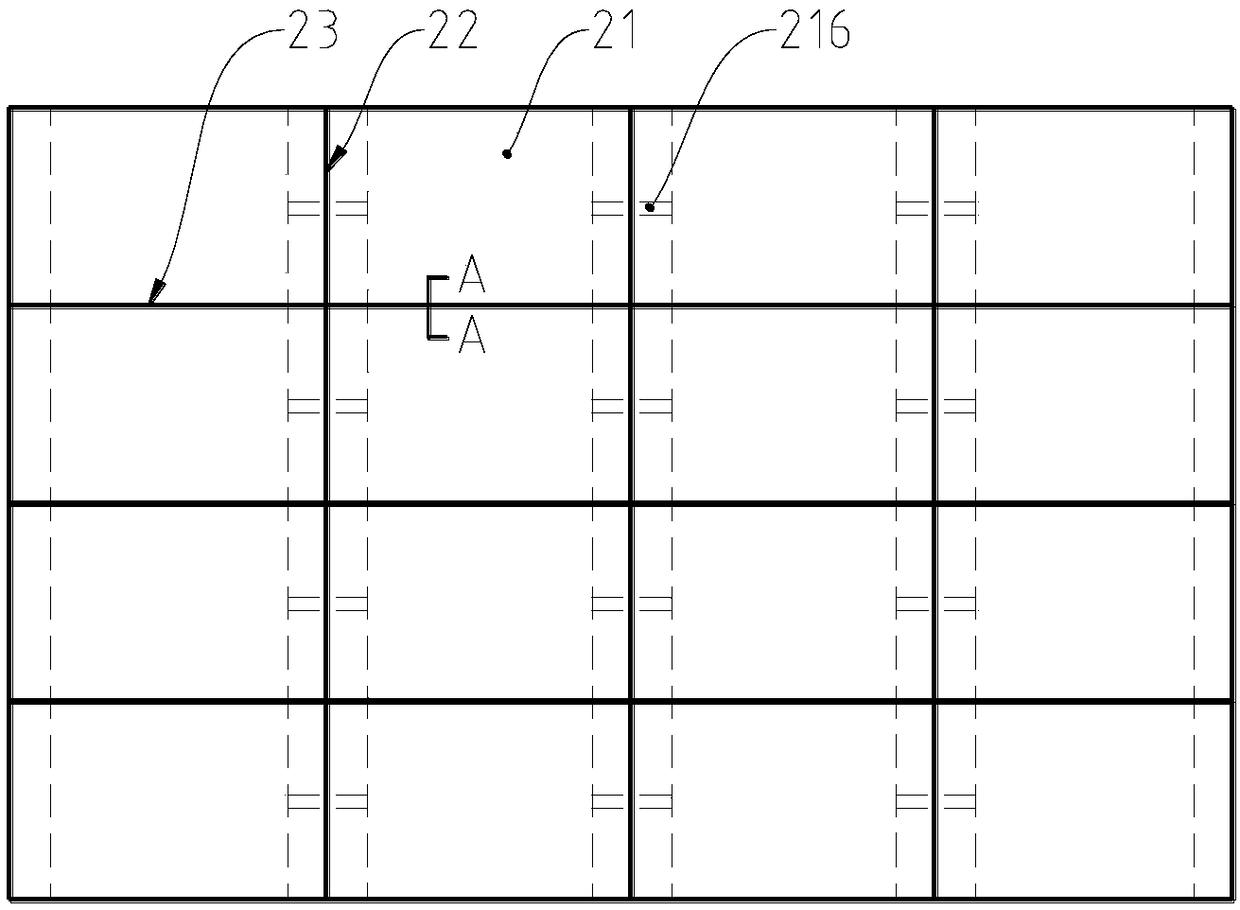

[0038] The inverted arch backfill layer along the longitudinal direction of the tunnel is formed by splicing a group of backfill units 2, and each backfill unit 2 along the tunnel ring directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com