Four-upright semi-submersible type floating wind turbine foundation with ballast

A wind turbine-based, semi-submersible technology, applied in the installation/support of wind turbine configuration, wind power generation, floating buildings, etc., can solve problems such as reducing the fatigue performance of infrastructure, inability to apply wind resource development, and gravity load asymmetry. , to achieve the effect of good overall anti-overturning performance, superior performance and lowering the height of the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

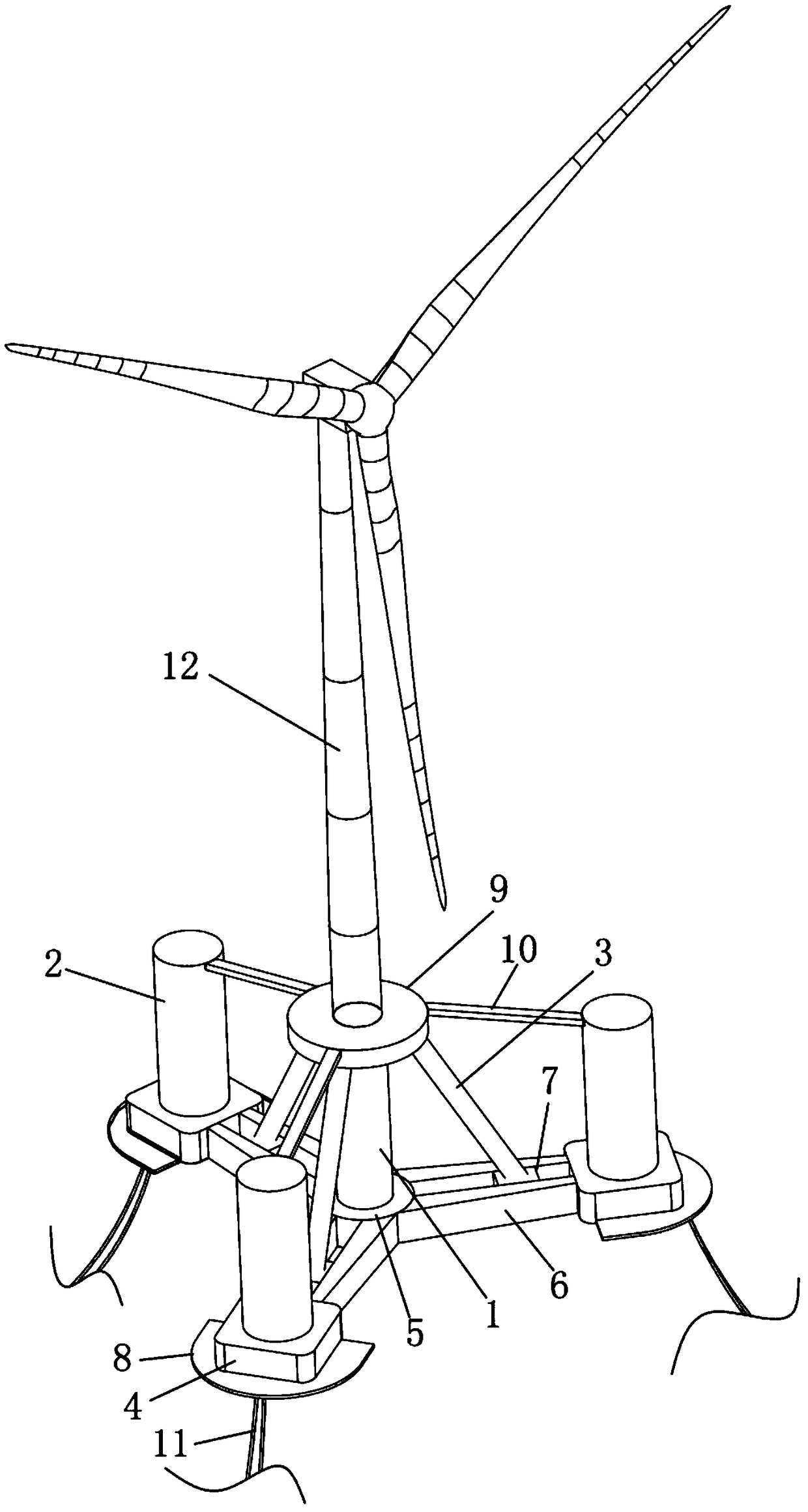

[0033] see figure 1As shown, the foundation of the four-column semi-submersible floating fan with ballast provided in this embodiment includes a central column 1, a side column 2, a diagonal brace 3, a square cabin 4, a circular cabin 5, a variable-section rectangular buoy 6, Connecting bridge 7, arc-shaped heave plate 8, transition platform 9, pedestrian trestle 10 and anchor chain 11; There are three side columns 2 located at the corners of an equilateral triangle with a side length of 65m, with a diameter of about 8m; Column 1 is located at the centroid of an equilateral triangle, with a diameter of about 10m; each side column 2 is placed on a square cabin 4 with a side length of about 15m, which has the function of ballasting and reducing the heave amplitude; the center column 1 is placed upright On a circular cabin 5 with a diameter of about 14m, it has the functions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com