Rolling mill roll bearing flat pressing combination assembling type sealing structure

A roll bearing and combined assembly technology, which is applied in the direction of engine seals, bearing components, shafts and bearings, can solve problems such as high cost, increased equipment maintenance costs, and increased production costs of steel plate rolling, so as to prevent quality damage and seal Reliable quality and reduced work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below according to the accompanying drawings.

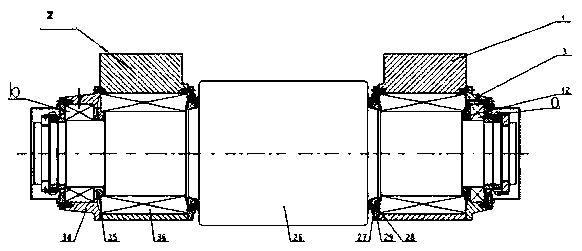

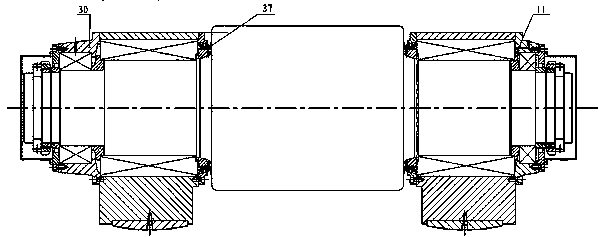

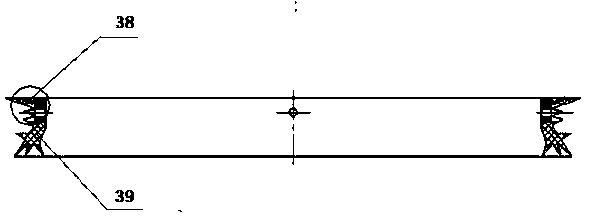

[0028] The rolling mill roll bearing flat-press combined assembly seal structure includes an upper roll and a lower roll. The upper roll and the lower roll respectively include a transmission end and an operation end. Bearing seat 1 on the end, and bearing seat 1 on the transmission end is installed with a bearing 36. The inner end cover 29 is installed on the side of the bearing 36 close to the upper roller surface. A sealing ring 28 is arranged between the bearing 36 and the upper roller of the largest diameter section. One end of the ring 28 is in contact with the bearing 36, and the other end is in contact with the side of the maximum diameter section of the upper roll. There are bolts 37 on the seal ring 28, and the seal ring 28 is connected to the support ring 27 through the bolts 37; on the other side of the center maximum diameter section There is an upper bearing s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap