Dehumidifier, cooling mechanism of dehumidifier and cooling method

A dehumidifier and compressor technology, applied in heating methods, household heating, space heating and ventilation details, etc., can solve problems such as affecting the life of the compressor, deformation and damage of injection molding parts, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

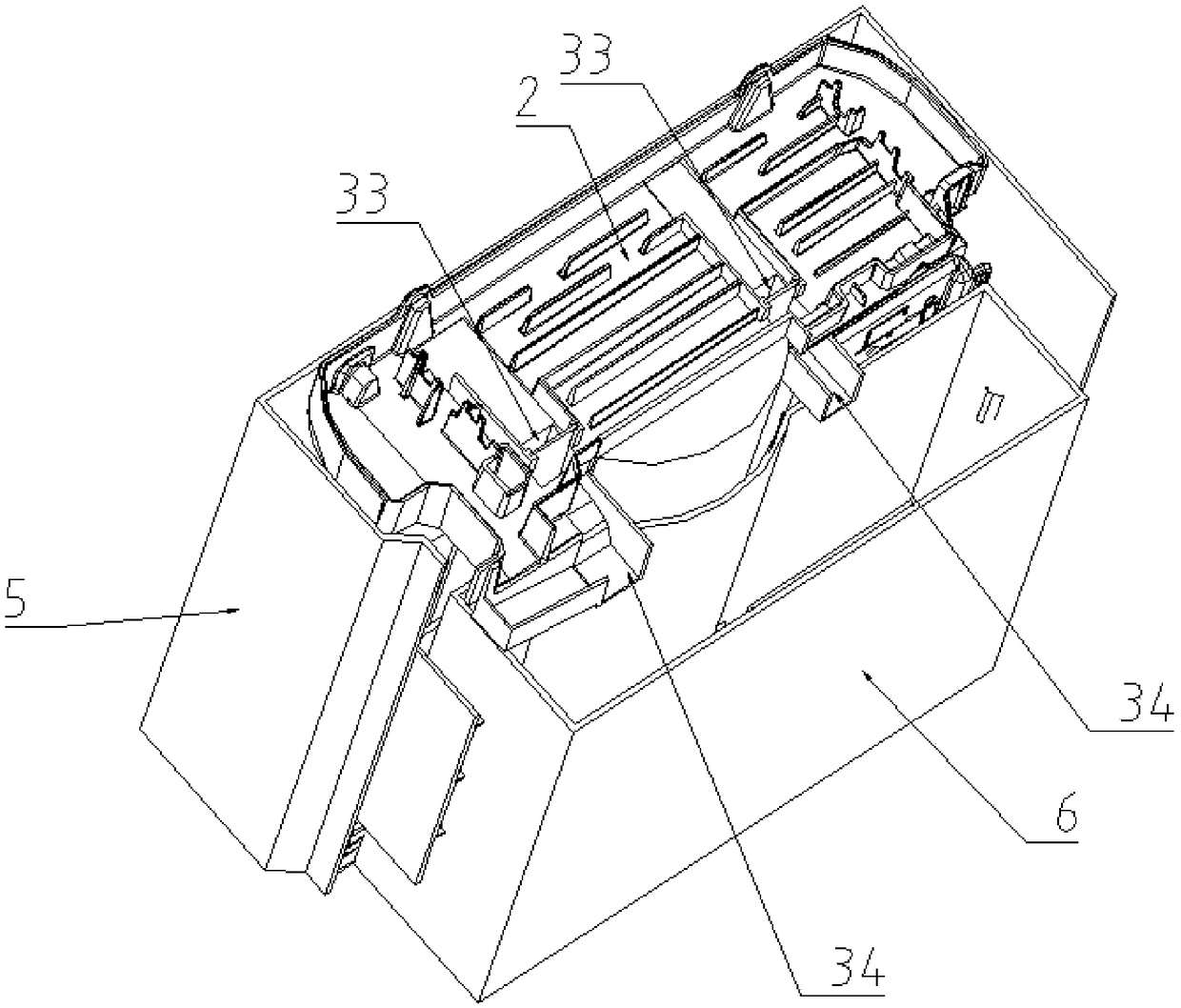

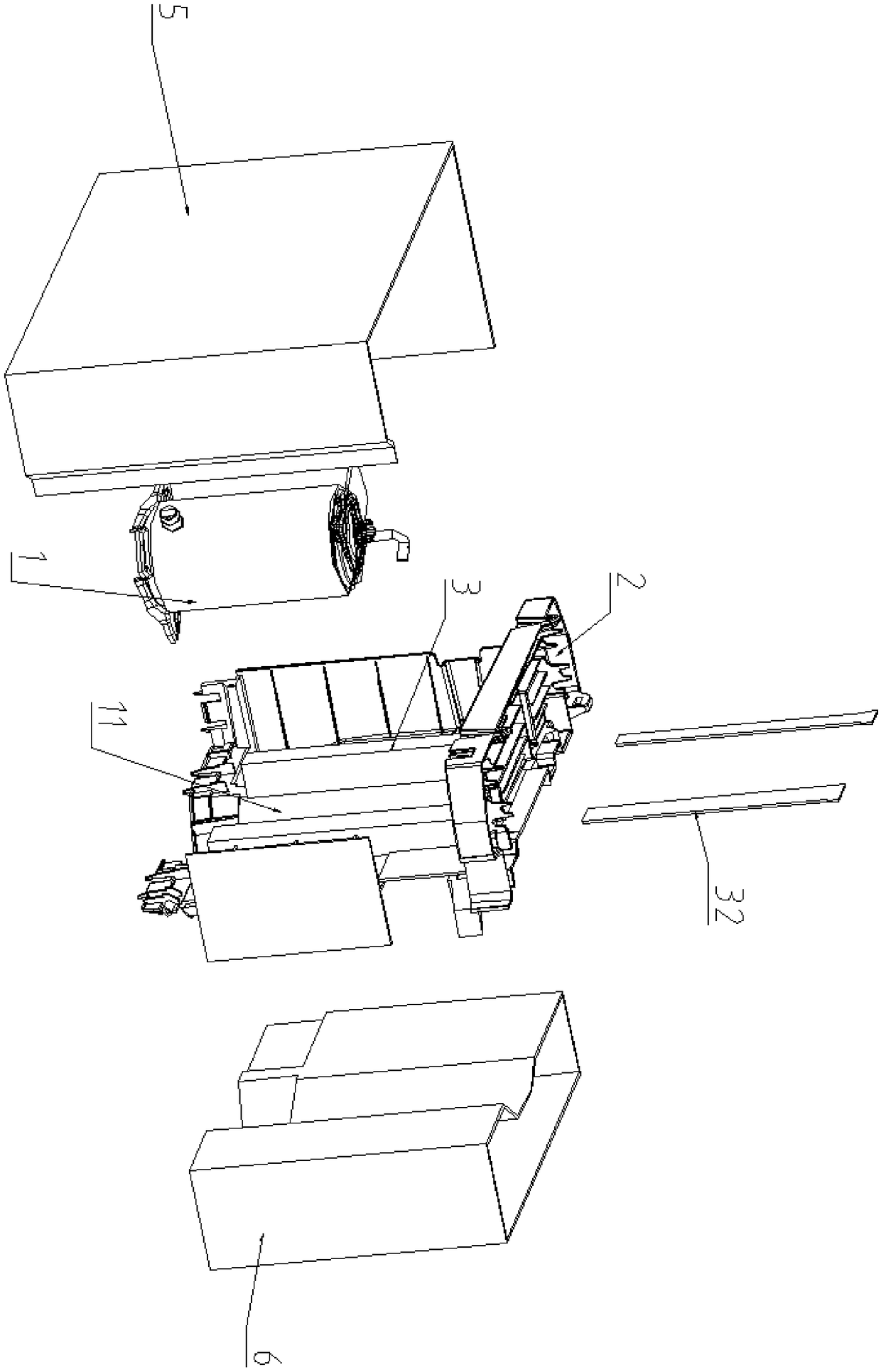

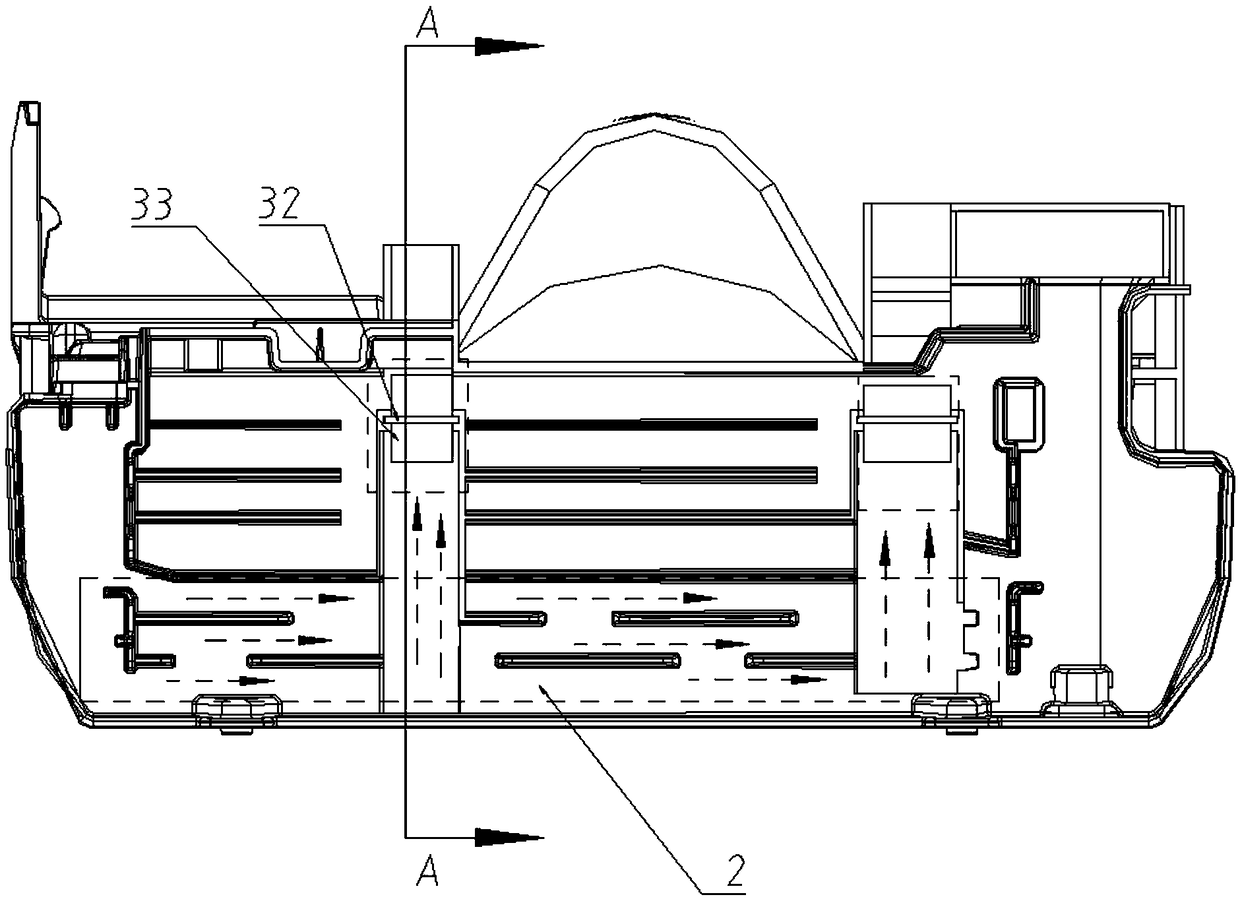

[0027] Such as Figure 1-4 Shown is a cooling mechanism for a dehumidifier, the dehumidifier includes a compressor 1 and a water receiving tray 2 for storing water generated during the dehumidification process, a compressor chamber 11 is formed under the water receiving tray 2, The compressor 1 is at least partially located in the compressor cavity 11 , and the cooling mechanism 3 is arranged in the compressor cavity 11 .

[0028] The cooling mechanism 3 includes a water channel 31 arranged below the water receiving tray 2 and a splint 32 inserted into the water channel 31, the upper ends of the splint 32 and the water channel 31 are fixed to the water receiving tray 2, and the splint 32 divides the water channel 31 into The cold runner and the hot runner communicate at the bottom of the water channel 31 .

[0029] A water inlet 33 is arranged on the cold runner, and the water inlet 33 is arranged in the water receiving tray 2 so that the condensed water in the water receivin...

Embodiment 2

[0037] For dehumidifiers with low dehumidification power, when the amount of condensed water is too small, the cooling effect of the cooling mechanism in the first embodiment is difficult to achieve. In view of this situation, one or more copper can be vertically arranged in the water channel 31 of the first embodiment. The lower end of the copper sheet extends to the bottom near the water channel 31, and the upper end is in contact with the evaporator or heat exchanger of the dehumidifier, and the heat in the water channel 31 can be transferred to the evaporator or heat exchanger through the copper sheet. Since the aluminum sheet for heat dissipation is arranged on the evaporator or the heat exchanger, the heat on the aluminum sheet can be transferred out through air cooling, and thus the heat generated by the compressor can be transferred out. The evaporator or heat exchanger belongs to the prior art and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com