Feeding system of powder metallurgy baking equipment

A technology of baking equipment and feeding system, applied in lighting and heating equipment, drying, drying solid materials, etc., can solve problems such as accidents, waste of raw materials, uneven tension, etc., to improve reliability and prolong service life , to maintain the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

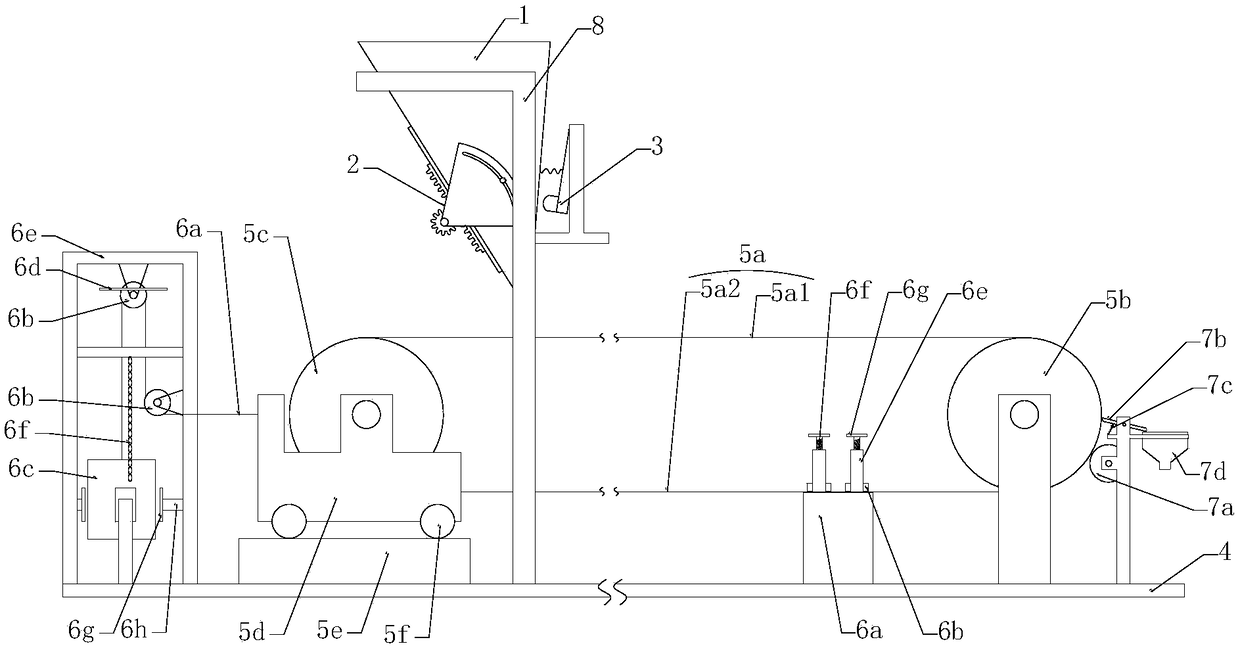

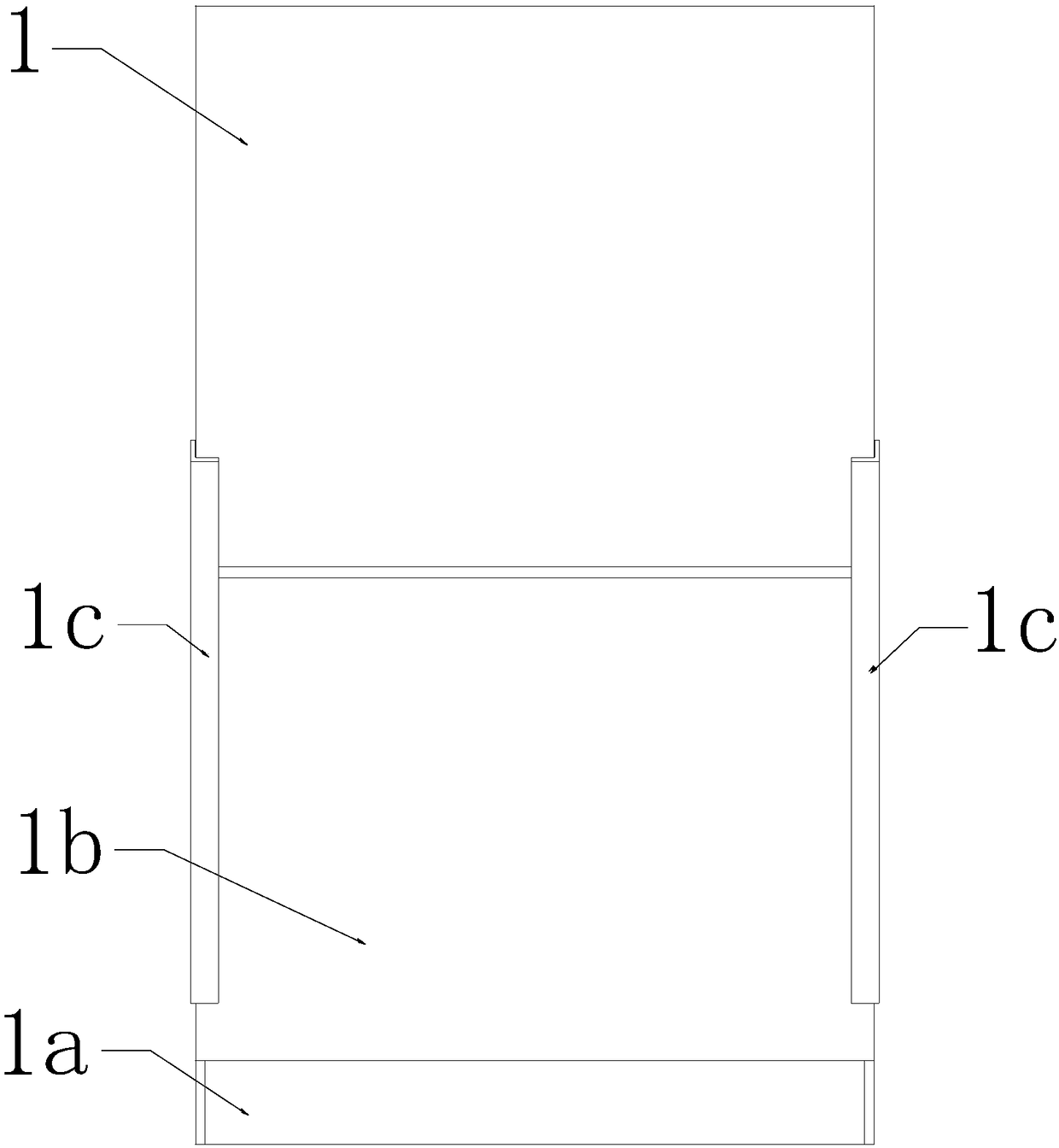

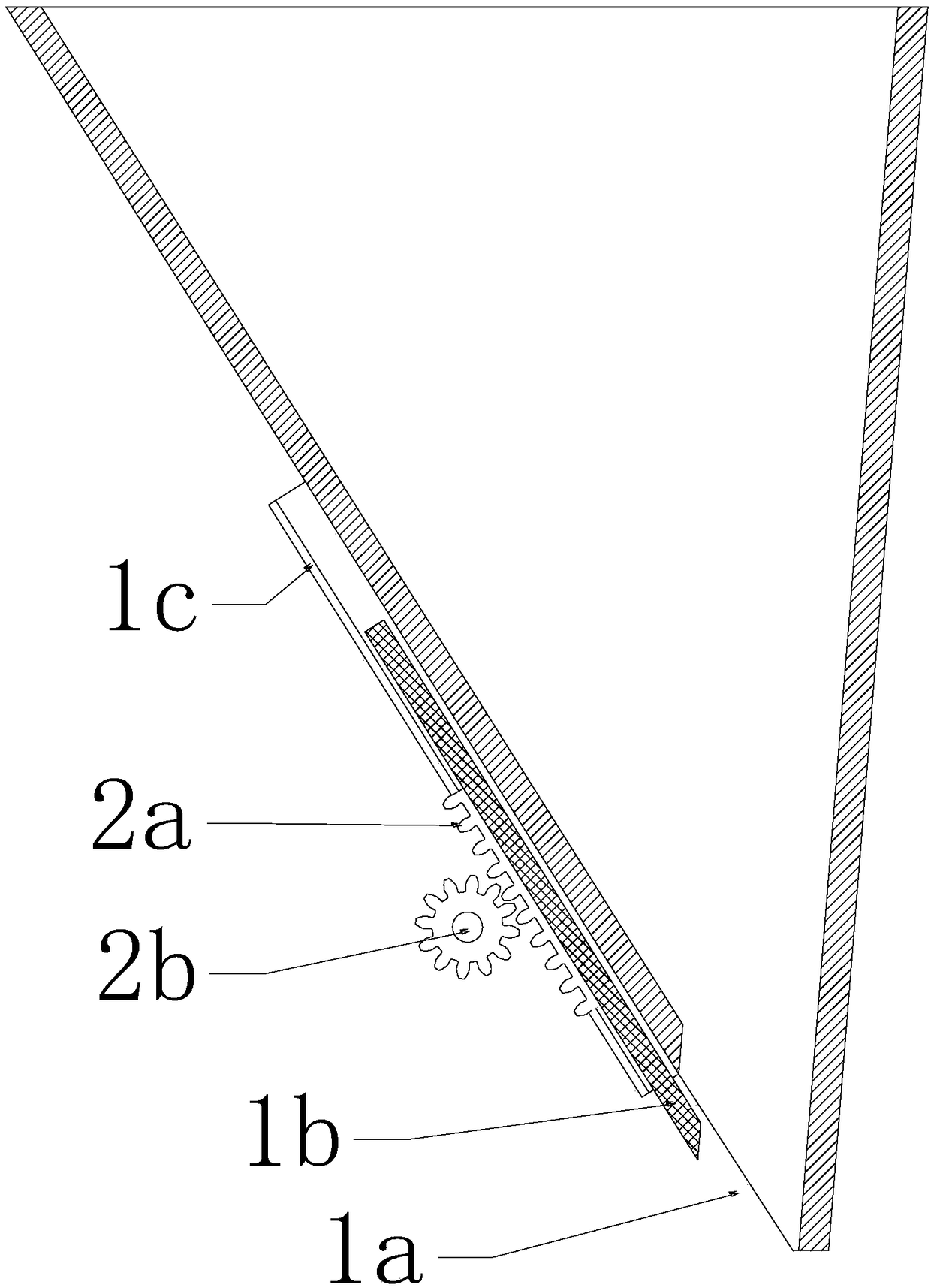

[0059] Such as figure 1 As shown, a powder metallurgy baking equipment feeding system includes a frame 4 and a conveyor belt assembly 5. The conveyor belt assembly 5 includes a feed roller 5c and a discharge roller 5b horizontally arranged on the frame 4, and a sleeve The conveyor belt 5a arranged on the feed roller 5c and the discharge roller 5b, the conveyor belt 5a circulates with the rotation of the feed roller 5c and the discharge roller 5b, thereby forming the feeding section 5a1 located above , the return section 5a2 located below, and the turning section around the feed roller 5c and the discharge roller 5b.

[0060] The discharge roller 5b is mounted on the frame 4 through a bearing, an adjustable-speed unloading mechanism is arranged above the feeding end of the conveyor belt 5a, and the feeding roller 5c is connected with a tensioning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com