Safety valve opening and closing pressure test device and method for simulating actual working condition

A technology of actual working conditions and opening and closing pressure, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as low detection efficiency, cumbersome operation, and inability to better simulate actual working conditions. achieve a compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

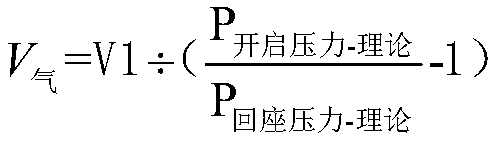

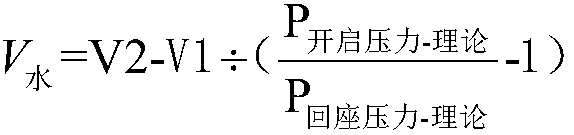

[0036] The invention provides a safety valve opening and closing pressure test device and method for simulating actual working conditions. By reasonably setting the ratio of gas and water, a smaller pressure tank can be used to simulate a large pressure tank filled with liquid in a workshop or factory building The opening and closing behavior of the safety valve used, so that the opening and closing pressure of the safety valve can be relatively accurately determined, and the dynamic characteristics of the safety valve can be observed when it is discharged. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

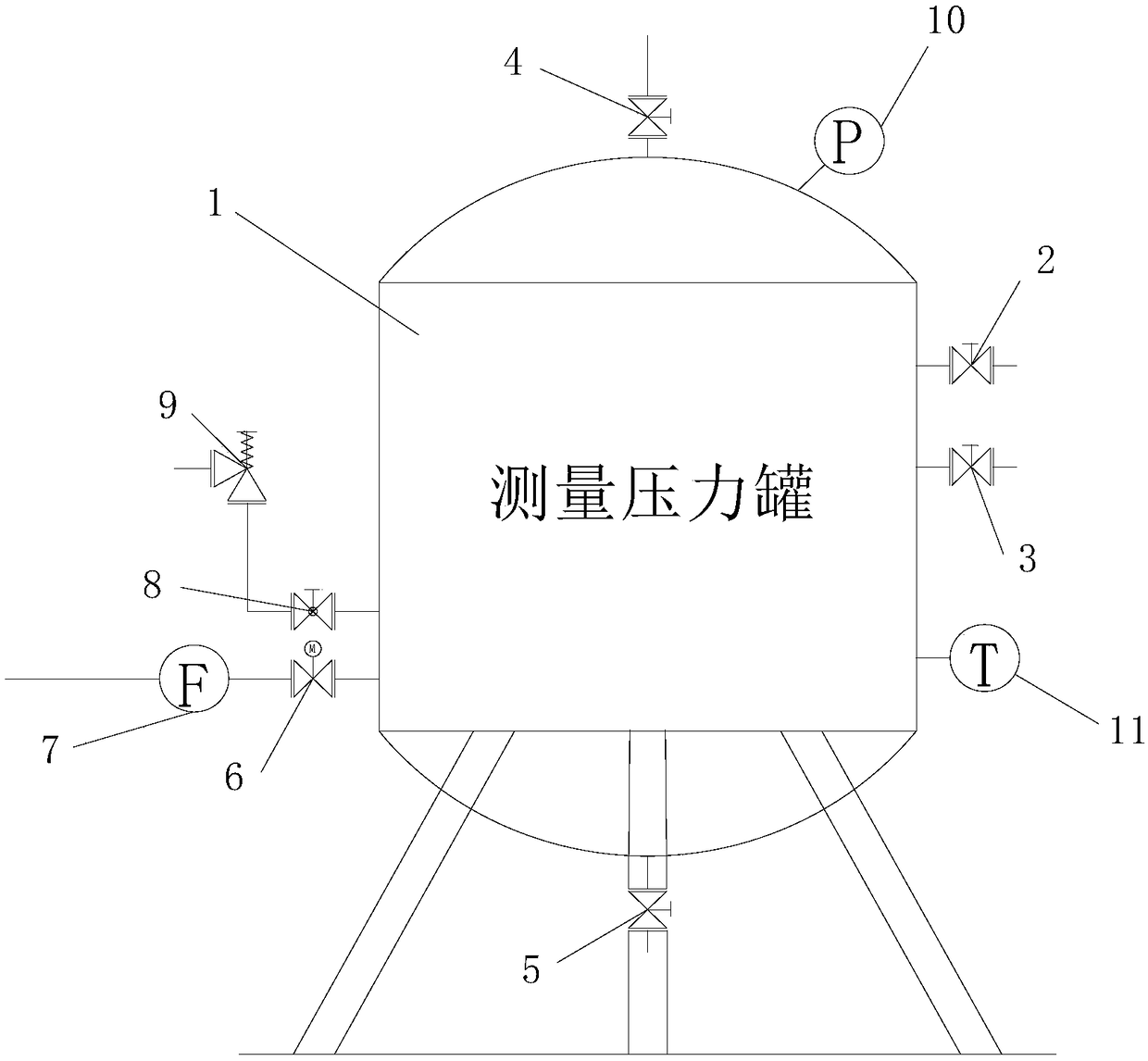

[0037] Such as figure 1 As shown, a safety valve opening and closing pressure test device capable of simulating the actual working conditions of the safety valve provided by the present invention includes a measuring pressure tank 1, a measuring assembly and a plurality of measuring valves, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage rating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com