Wire drawing machine control method, device, wire drawing machine control device and storage medium

A wire drawing machine and wire drawing technology, applied in the field of wire drawing machines, can solve problems such as low control accuracy, easy damage to the tension swing rod, and easy failure of the potentiometer, so as to improve control accuracy, avoid wire breakage or uneven winding, Avoid Controlling Inaccurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

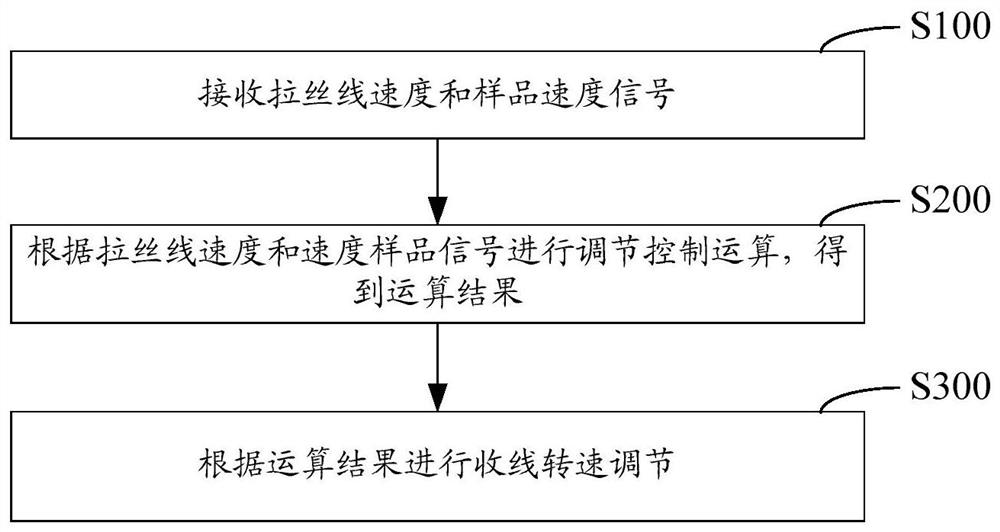

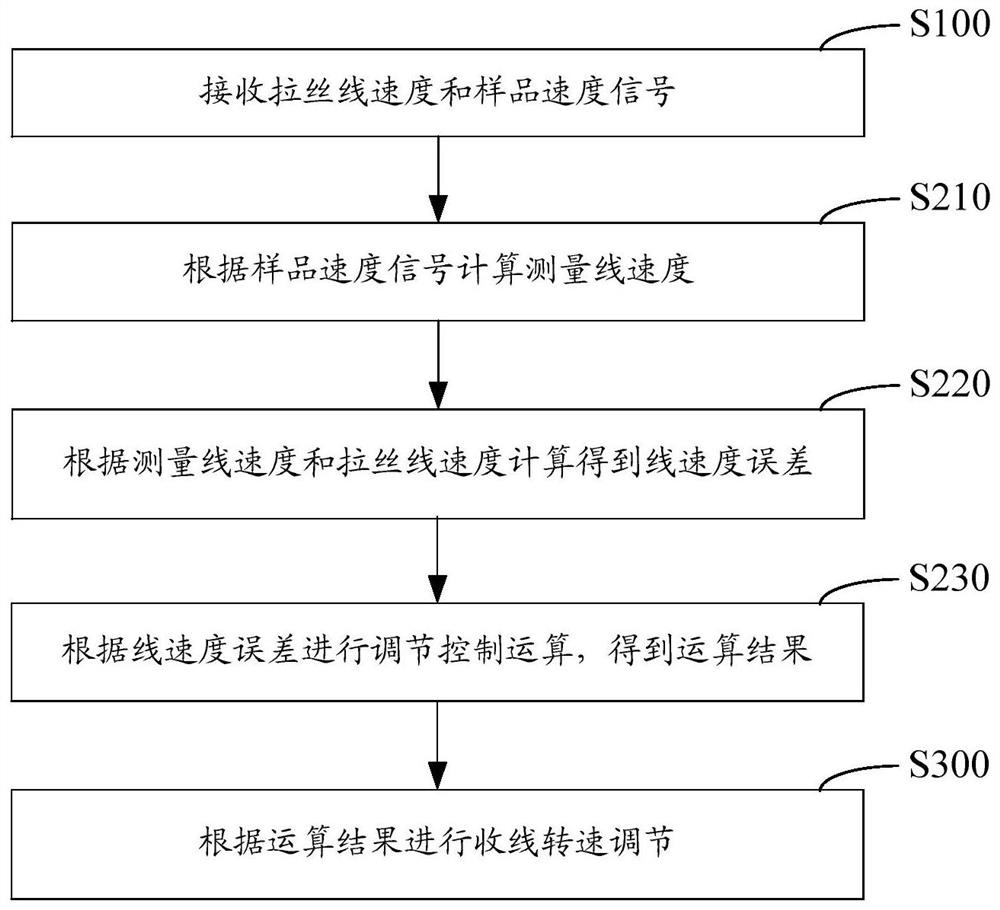

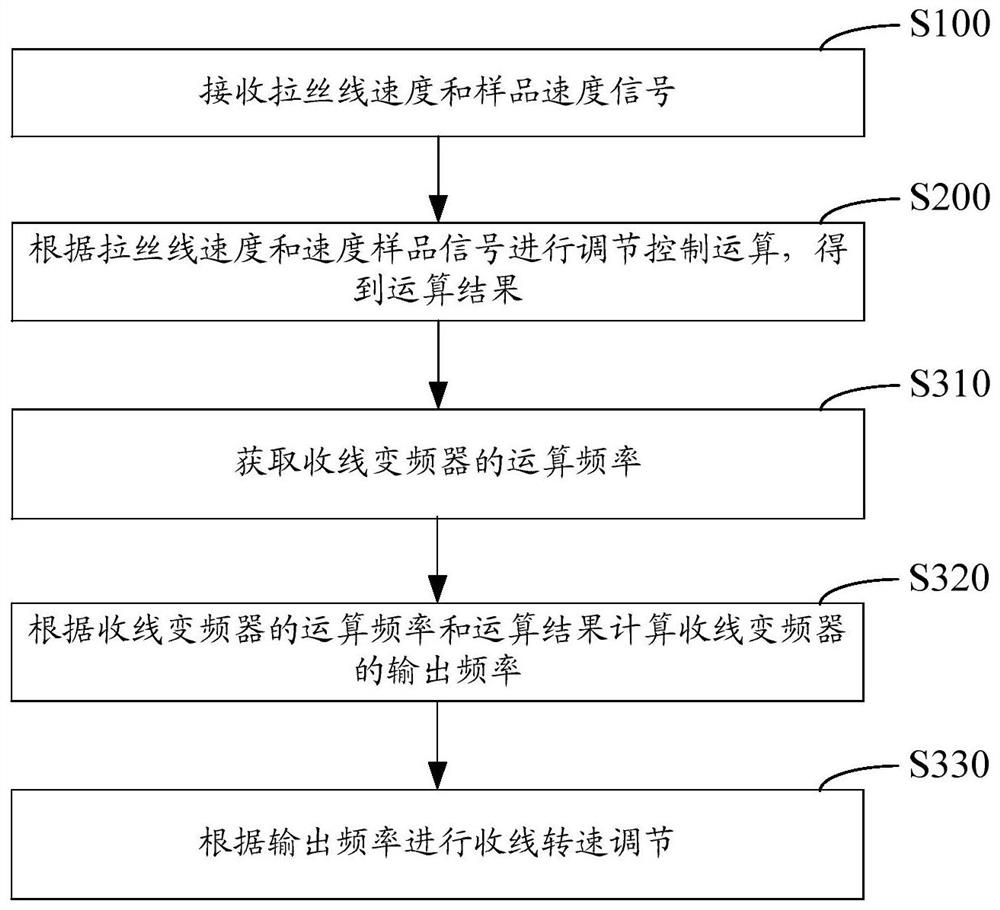

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

[0052] The wire drawing machine control method provided in this application can be applied to industries such as machinery manufacturing, hardware processing, petrochemical industry, plastics, bamboo and wood products, electric wire and cable, etc. Specifically, it can produce and pre-process metal products such as steel wire, rope wire, prestressed steel wire, and standard parts. Among them, the linear speed operation command of the wire drawing machine control method can be issued through the terminal, and the terminal can be but not limited to various personal computers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com