Block chain-based sleeve grouting quality traceability method and system, and collection terminal

A technology of sleeve grouting and collection terminal, applied in transmission systems, digital transmission systems, collaborative devices, etc., can solve the problems of poor traceability, easy loss, scattered and incomplete grouting event data, etc., to achieve decentralization , Improve transparency and quality management, and achieve immutable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

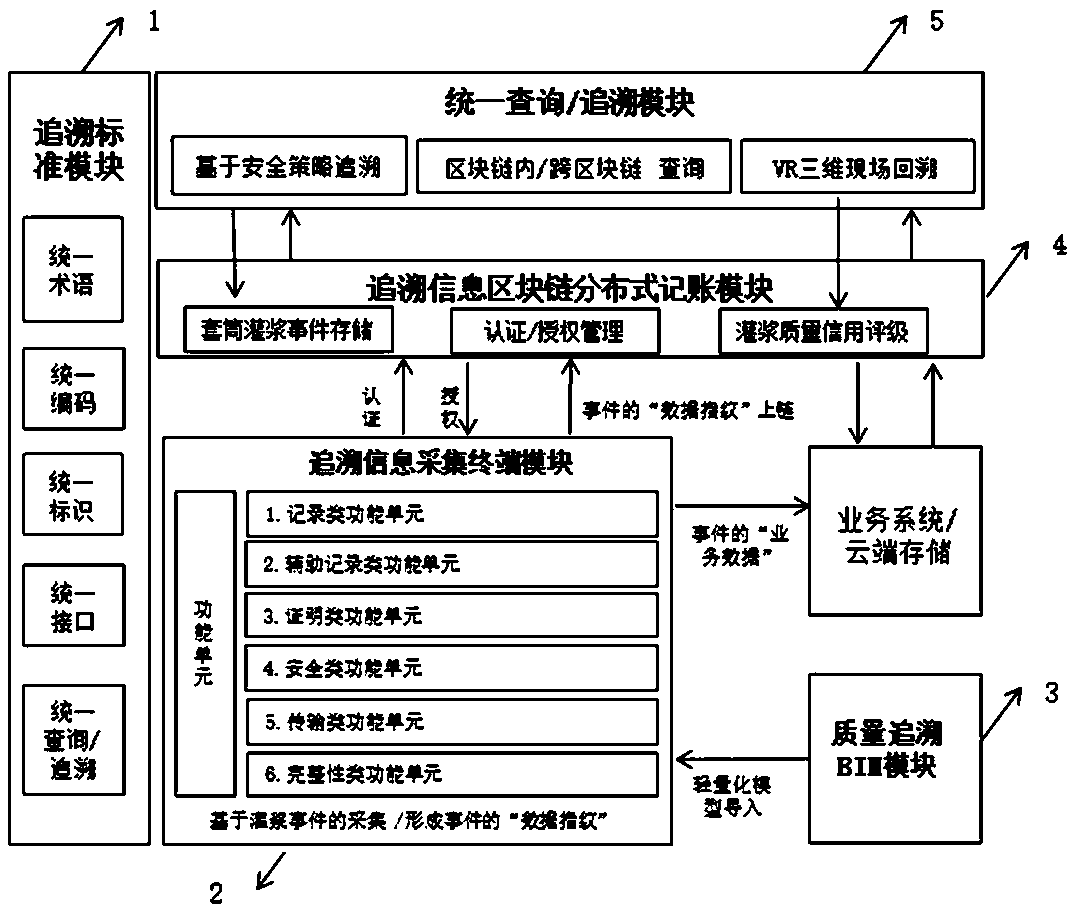

[0064] In order to solve the problem that the quality information of sleeve grouting in the field of construction industrialization cannot be traced in the whole construction process in the prior art, the embodiment of the present invention provides a method, system and collection terminal for sleeve grouting quality traceability based on blockchain.

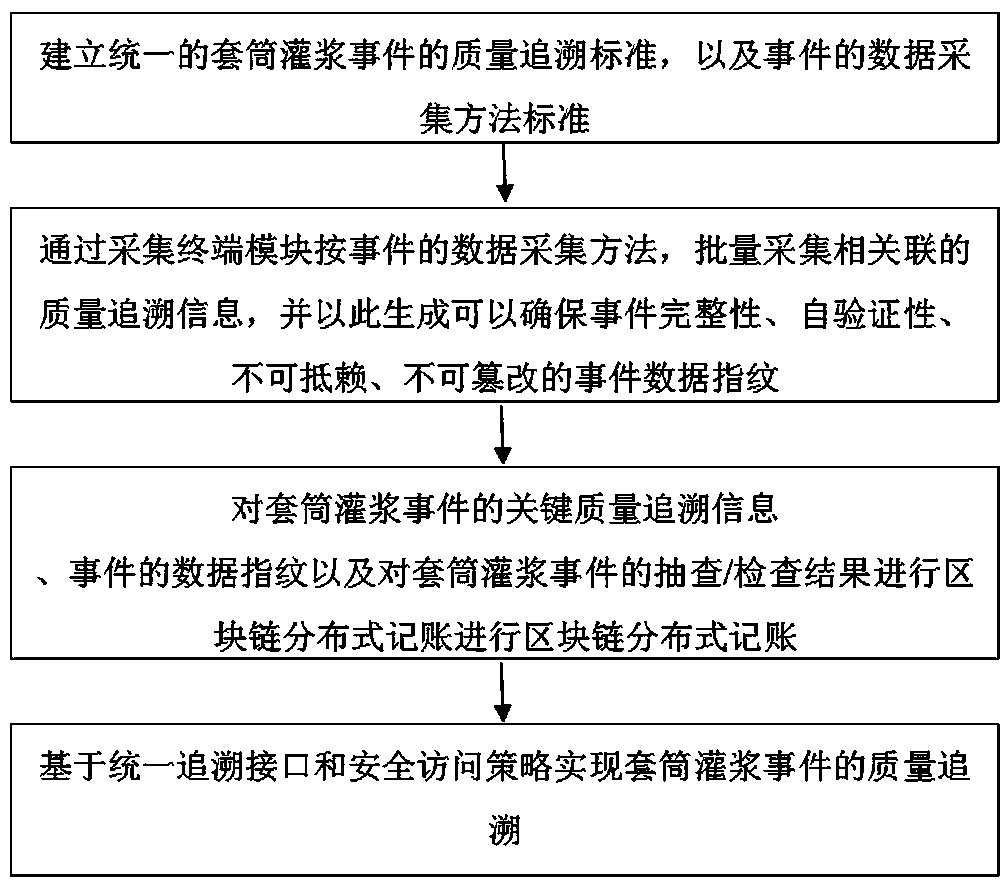

[0065] Such as figure 1 Shown is the flowchart of the embodiment of the present invention, the method provided by the embodiment of the present invention includes the following

[0066] Step S1: Establish a unified quality traceability standard for sleeve grouting events, and event data collection methods (including a unified process, event data fingerprint algorithm);

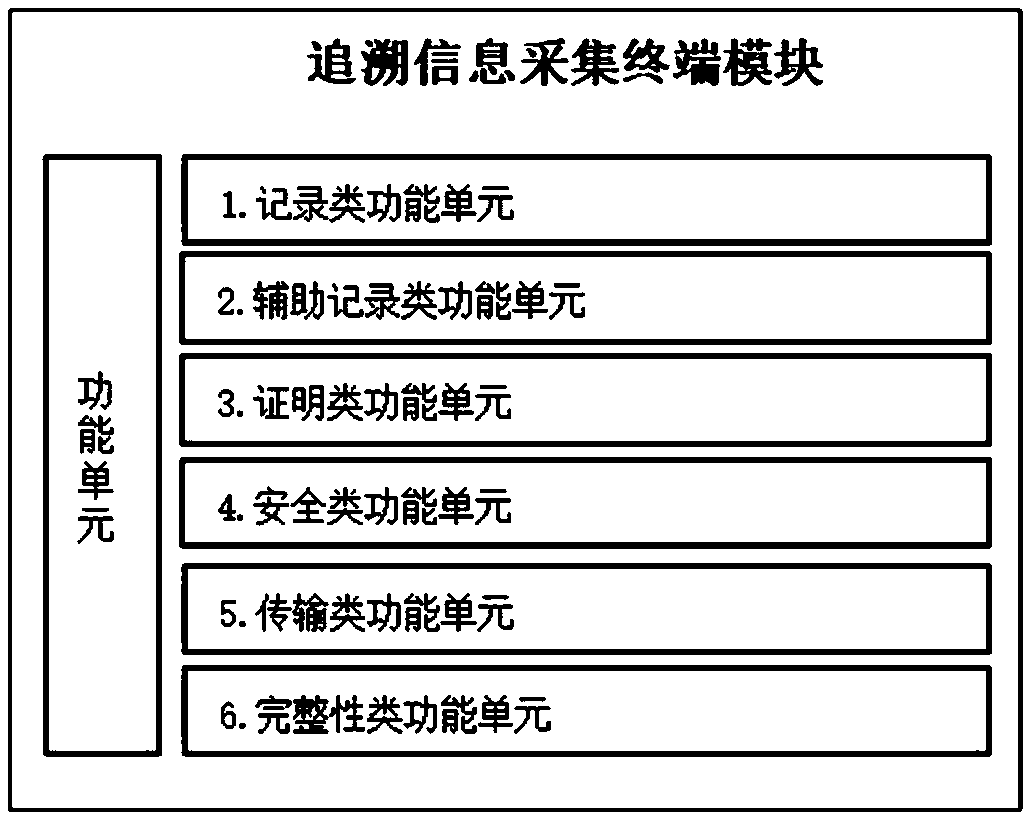

[0067] Step S2: Collect the associated quality traceability information (business data) in batches through the data collection method of the terminal module by event, and generate event data fingerprints that can ensure event integrity, self-verification, non-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com