Diode lead sealing treatment process

A processing technology and diode technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult to control the uniformity of lead glue, difficult to ensure the uniformity of distribution, and difficult to meet market demand, etc. The effect of convenient loading and unloading, improving yield and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

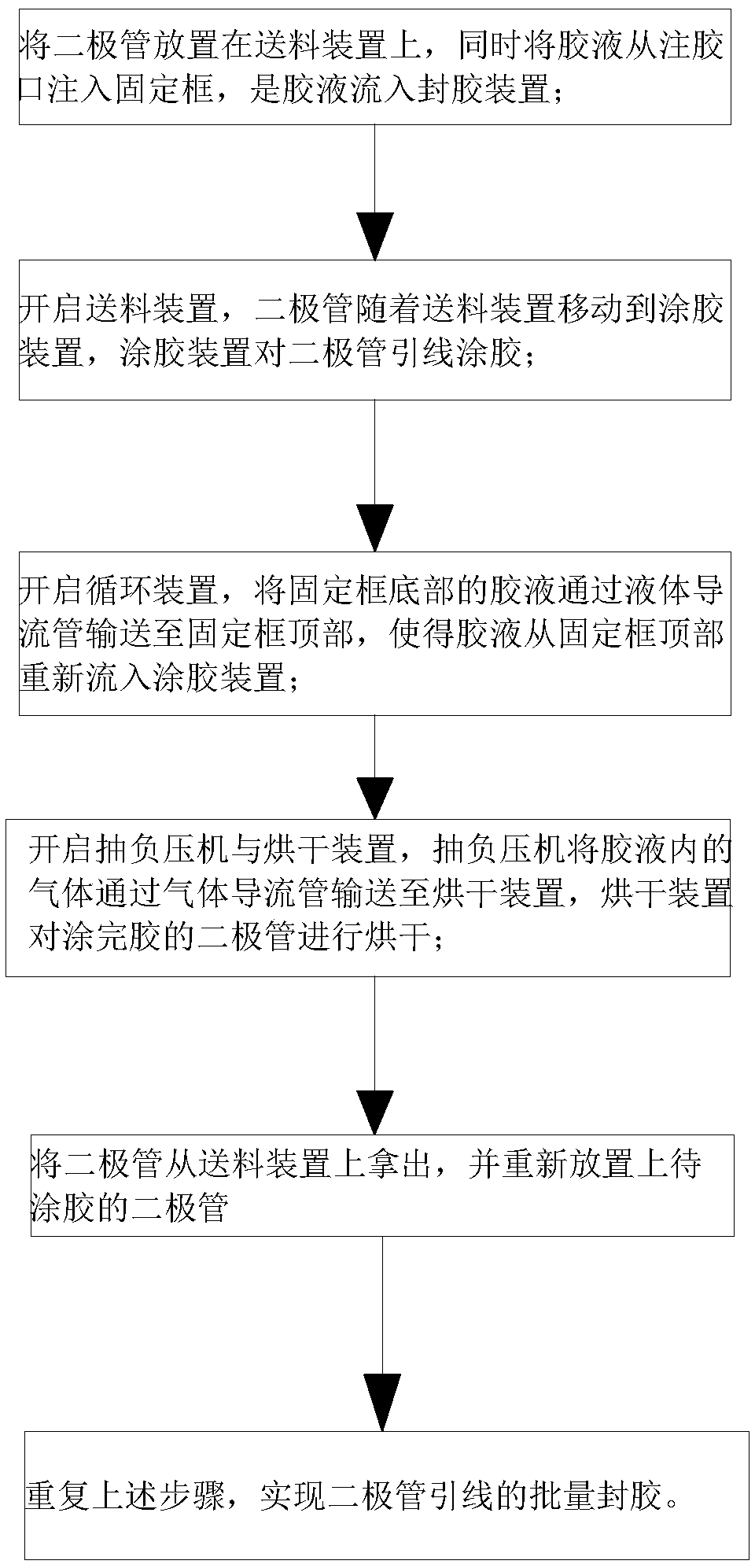

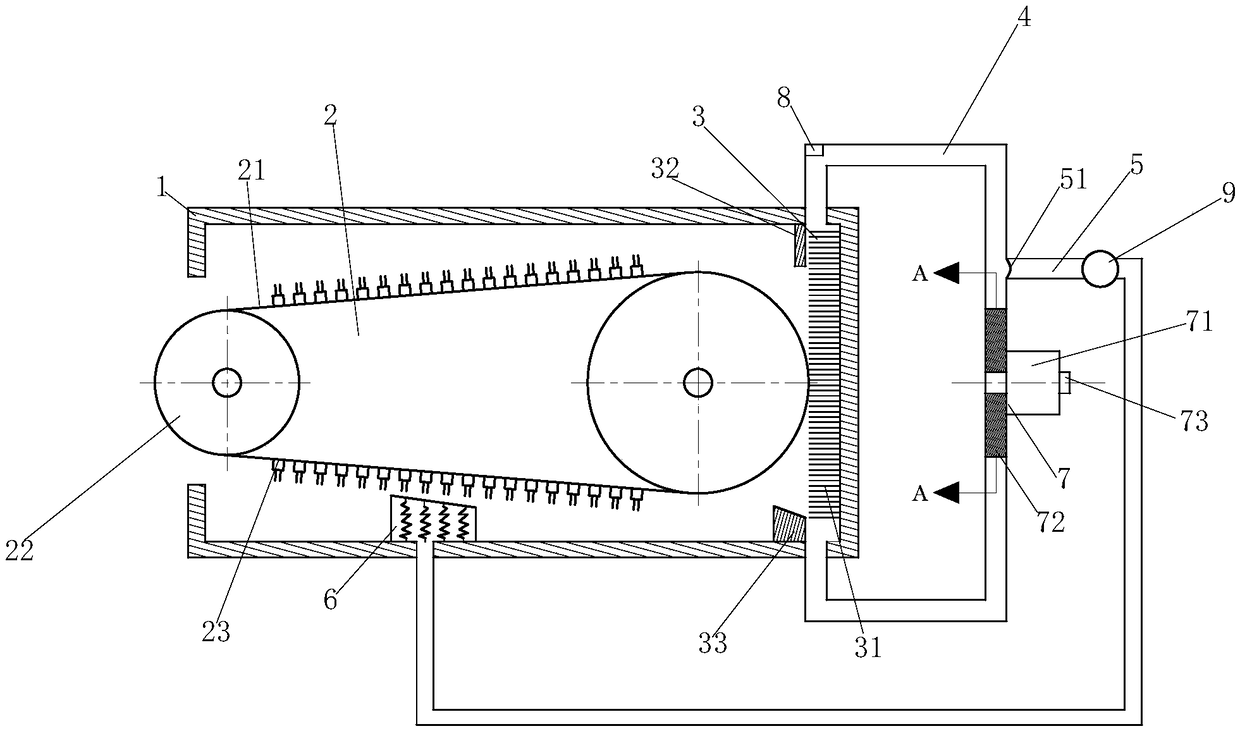

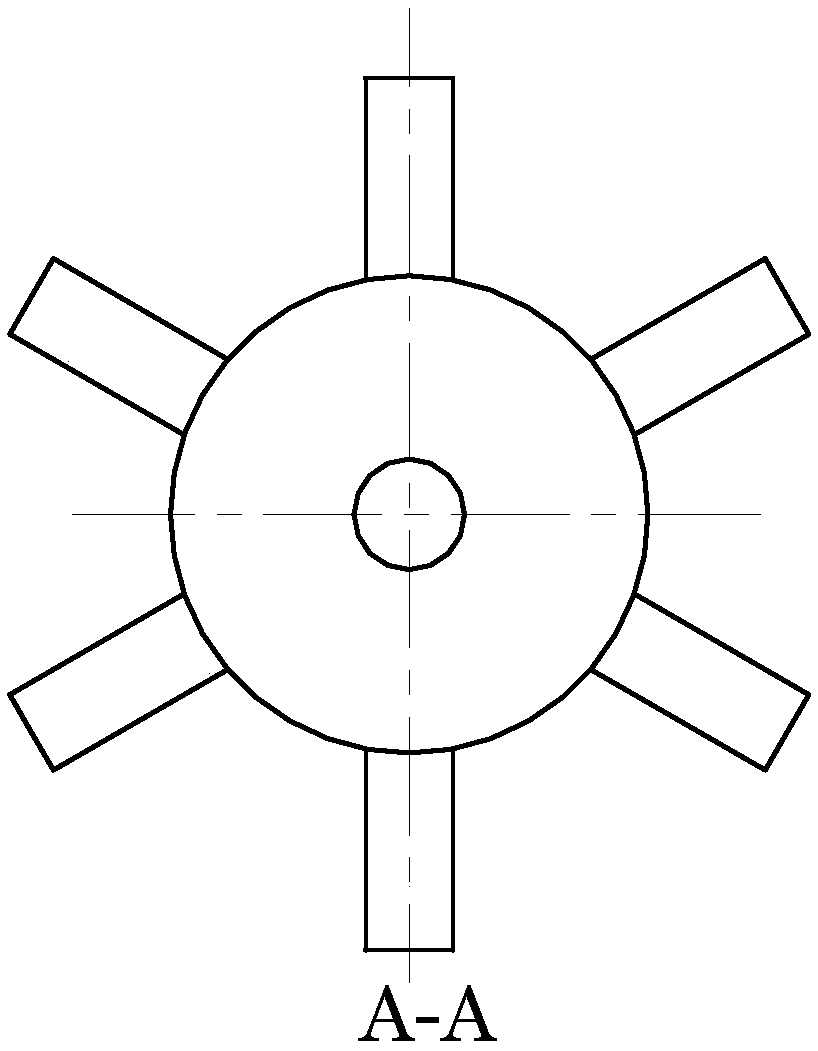

[0030] Such as Figure 1 to Figure 5 As shown in the present invention, a diode lead wire sealing treatment process, the method adopts the following gluing device, the gluing device includes a fixed bracket 1, a feeding device 2, a gluing device 3, a liquid guide tube 4, a gas Guide pipe 5, drying device 6, circulation device 7 and negative pressure pump 9; the feeding device 2 is located inside the fixed bracket 1, and the feeding device 2 is used for the input and output of diodes; the gluing device 3 is located in On the right side of the fixed bracket 1, the gluing device 3 is used to apply glue to the diode lead; The other end is fixed below the fixed bracket 1, and the liquid guide tube 4 is provided with a glue injection port 8, which is u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap