Baking device, system and method thereof for verifying wafer aging

A technology for baking devices and wafers, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as test failures, personnel burns, oven temperature, and wind speed changes that cannot be automatically acquired and stored, so as to improve production. Manufacturing process, high degree of automation, and the effect of improving test quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

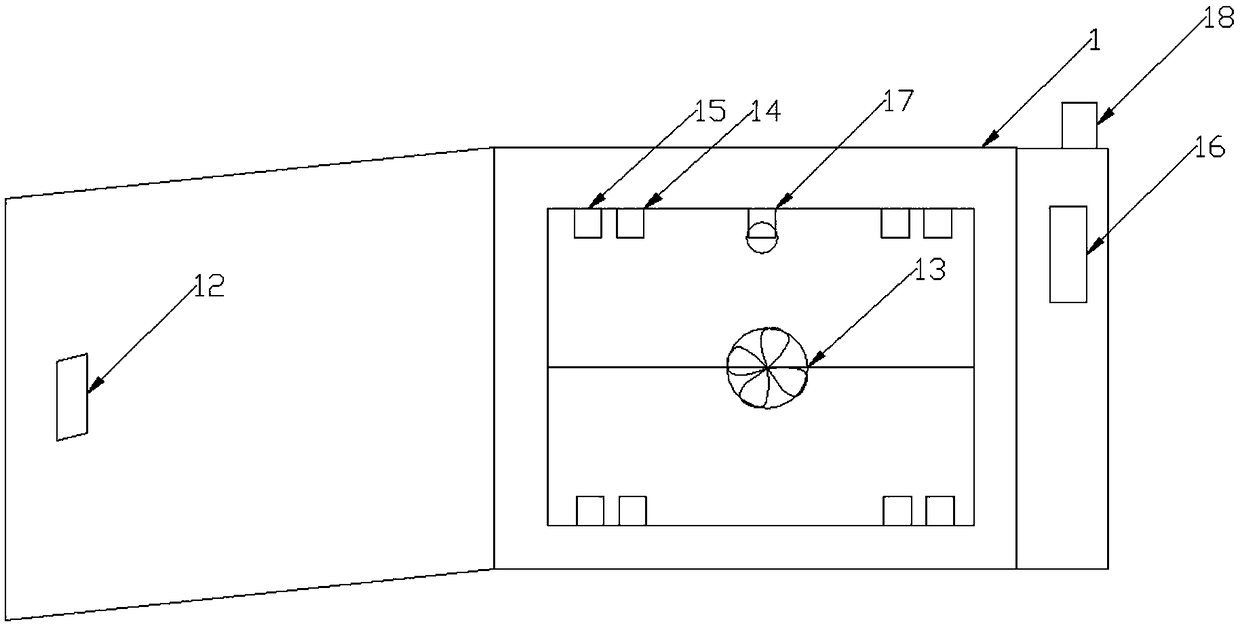

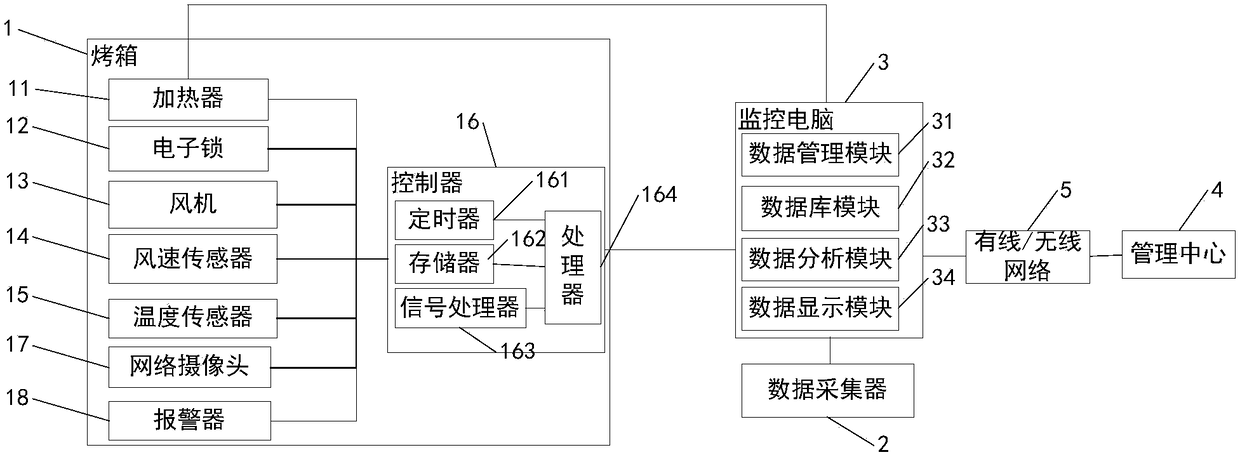

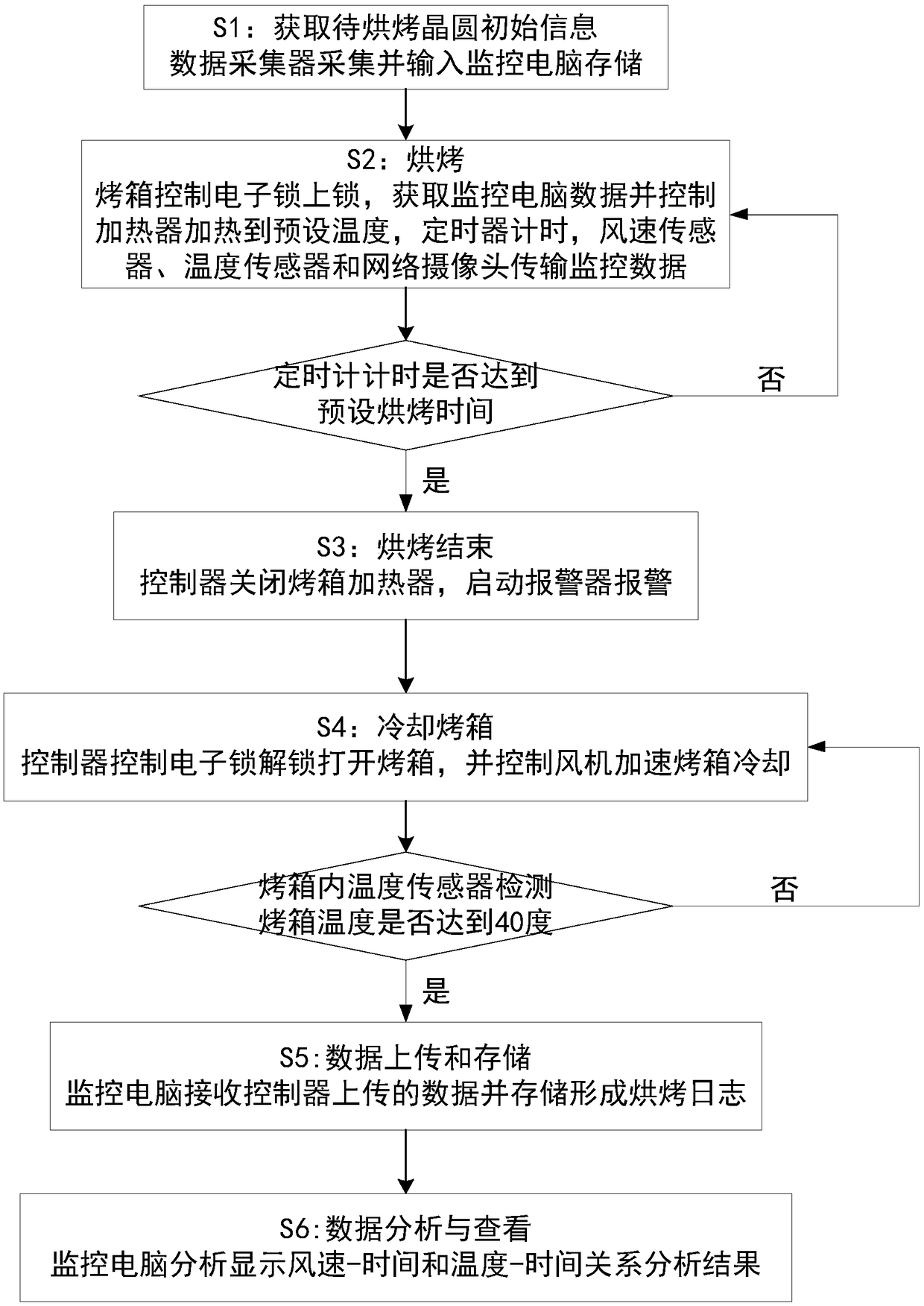

[0032] like figure 1 and figure 2 As shown, a baking device for verifying wafer aging includes an oven 1, the oven 1 includes a heater 11, an electronic lock 12, a fan 13, a wind speed sensor 14, a temperature sensor 15 and a controller 16, the heater 11, an electronic lock 12. The fan 13, the wind speed sensor 14 and the temperature sensor 15 are electrically connected to the controller 16.

[0033] There are four wind speed sensors 14 and four temperature sensors 15 respectively, and the wind speed sensors 14 and the temperature sensors 15 are respectively arranged at four corners of the inner wall of the oven 1 .

[0034] Concrete, also comprise network camera 17 and alarm 18, network camera 17 is arranged on the oven 1 inner wall top center below, alarm 18 is arranged on oven 1 outer wall top, network camera 17 and alarm 18 are connected with controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com