Large external rotor permanent magnet synchronous motor permanent magnet rotor wireless temperature monitoring device

A permanent magnet synchronous and permanent magnet rotor technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of limited transmission battery capacity, signal susceptibility to magnetic field interference, large maintenance, etc., to prevent permanent magnetic steel Loss of magnetization accident, working environment temperature is good, and the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

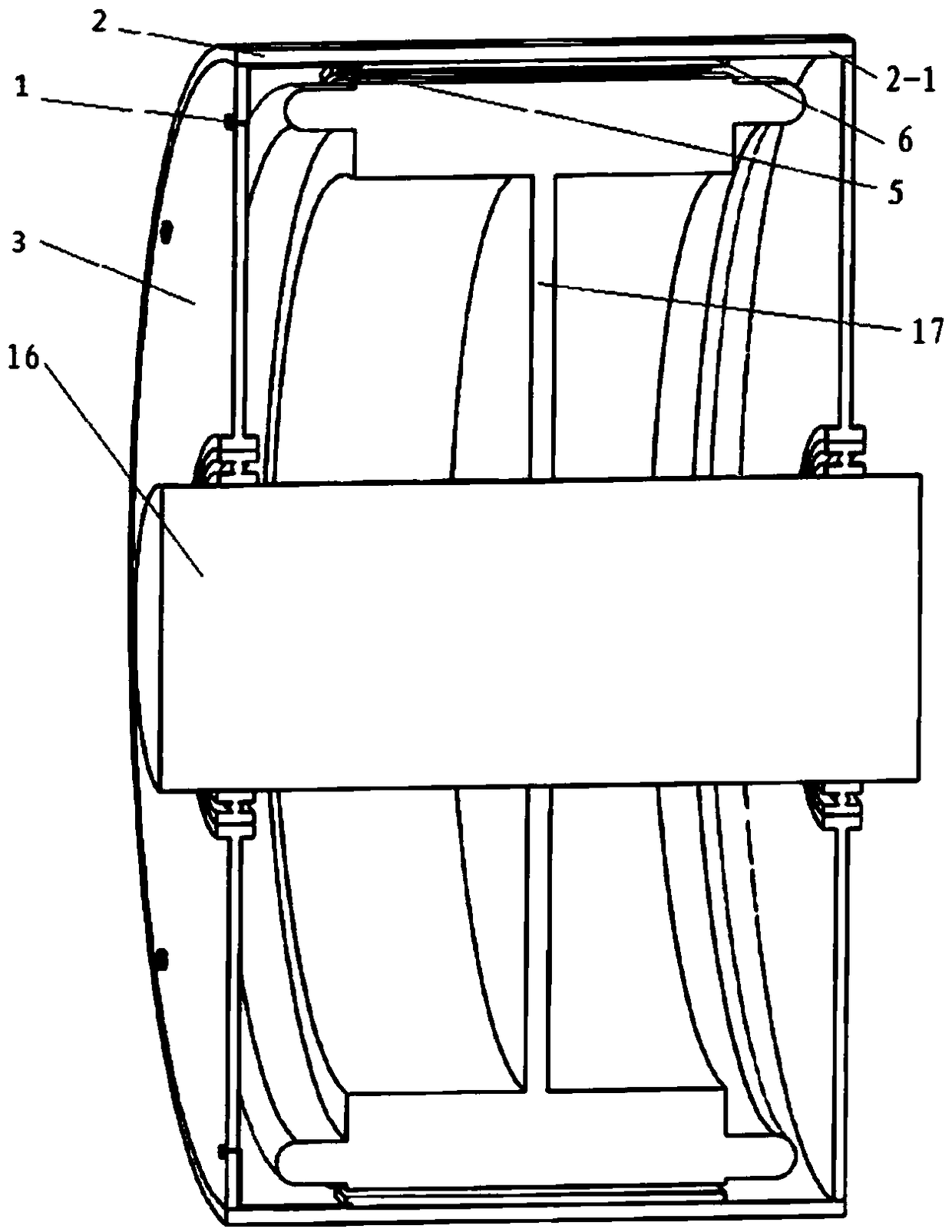

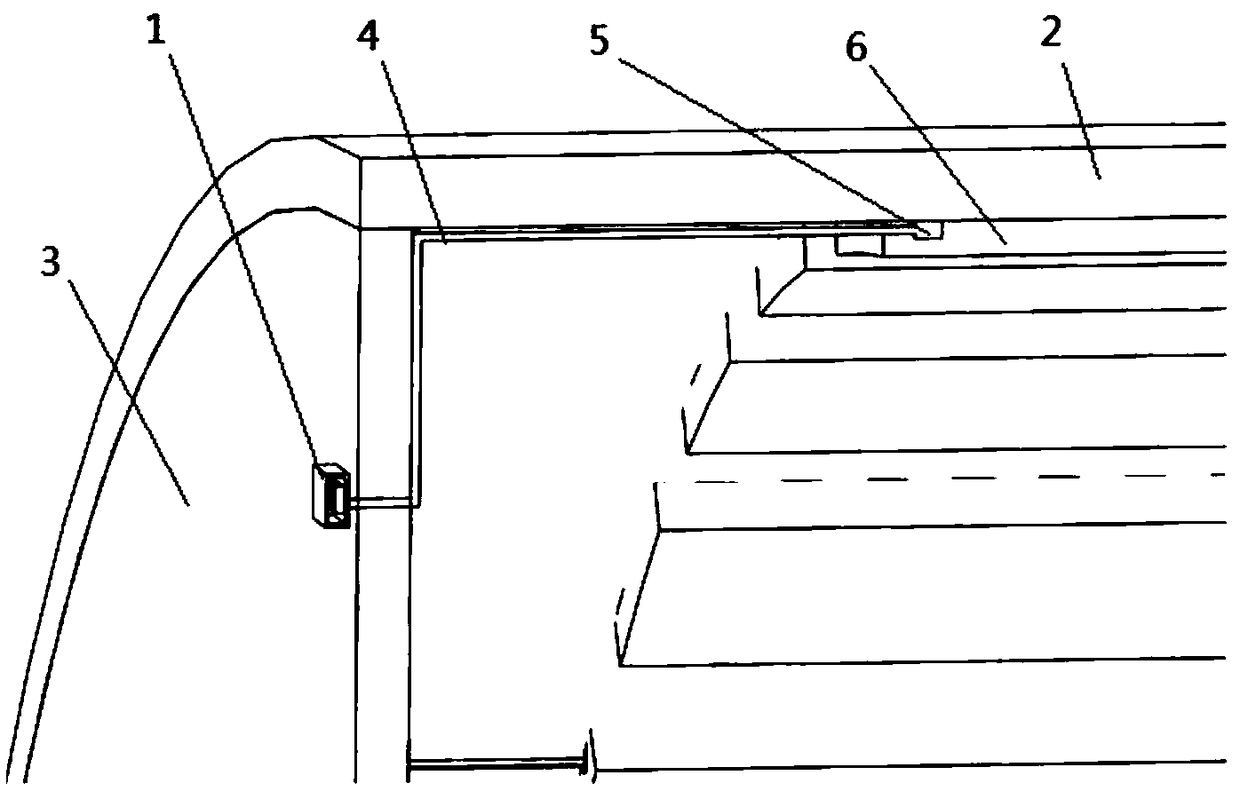

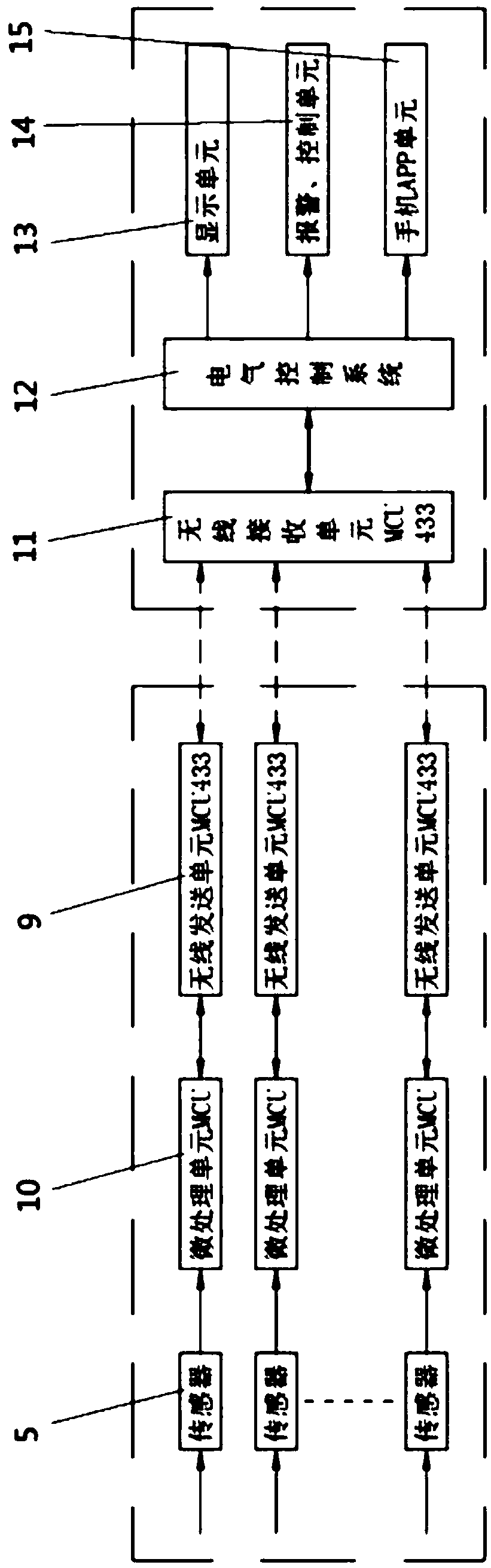

[0020] see figure 1 , figure 2 , a large-scale outer rotor permanent magnet synchronous motor permanent magnet rotor wireless temperature monitoring device, the outer rotor permanent magnet synchronous motor is composed of a motor shaft, a stator bracket, a stator, a permanent magnet rotor 2, and an end plate 3. The permanent magnet rotor 2 is composed of a rotor casing and a permanent magnet pole 6. The stator bracket is installed on the motor shaft, the stator is installed on the stator bracket, the rotor casing is set on the stator, and the permanent magnet pole 6 is installed on the inner wall of the rotor casing. End plates 3 are installed at both ends of the rotor casing. The temperature monitoring point of the permanent magnet pole 6 is equipped with a sensor 5, the sensor 5 is close to the permanent magnet pole 6 of the rotor, the sensor 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com