Ion chemical heat treating furnace having glow discharge-aided heating function

A technology of chemical heat treatment and glow discharge, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of low heating efficiency of ion chemical heat treatment furnace, increase of cost of ion chemical heat treatment furnace, large effective working space and other problems, to achieve the effect of solving the difficulty of temperature measurement, reducing arc discharge, and improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

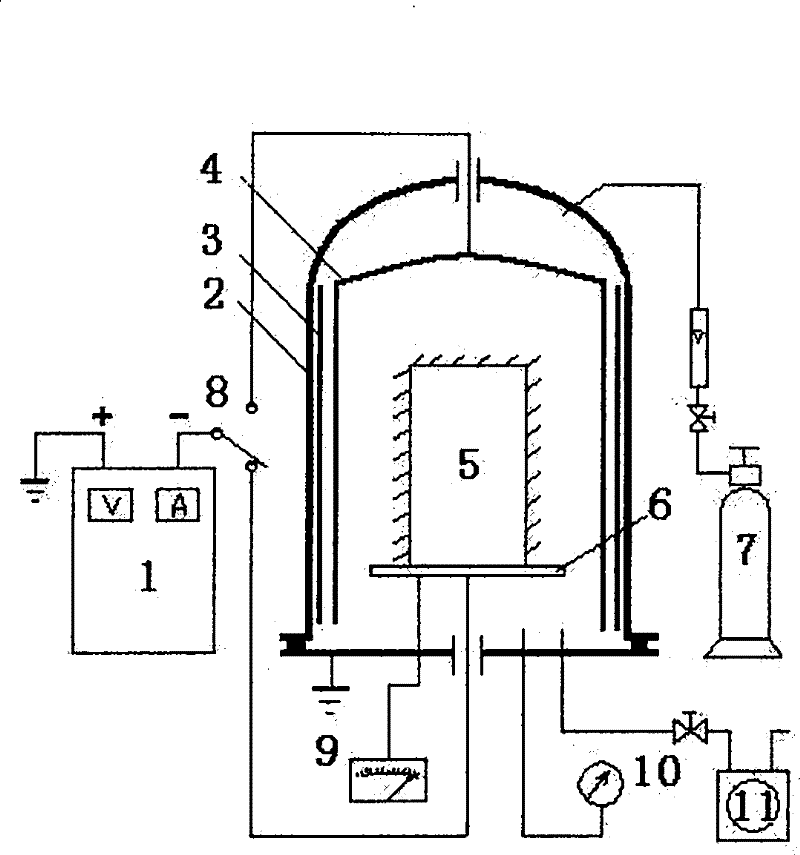

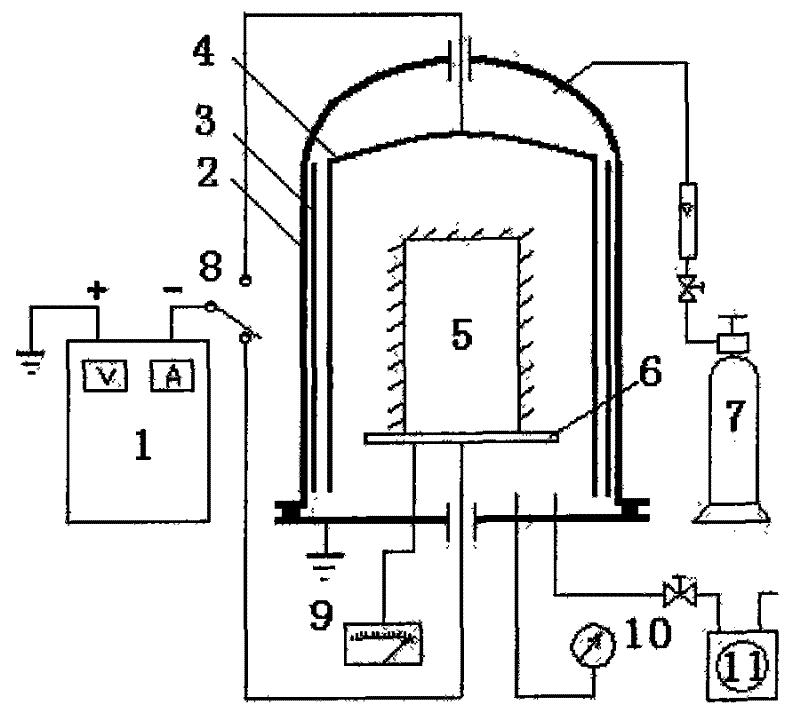

[0015] Embodiment 1: the inner diameter of the ion chemical heat treatment furnace of the present invention is φ650 × 1200 millimeters, and a cylinder with a thickness of 1 millimeter is placed in the furnace, and the size is φ550 × 900 millimeters, and 200 kilograms are placed on the workbench For workpieces to be treated by ion nitriding, ammonia gas is used as the working gas for ion nitriding. In the initial stage of ion nitriding treatment, the negative electrode of the DC power supply is connected to the cylinder first, and the cylinder starts to be heated by glow discharge. At this time, the DC voltage is 750V, the DC current is 20A, and the gas pressure in the furnace is 200Pa. When the workpiece is heated to 400°C, switch the negative pole of the DC power supply to the workbench, and the workpiece starts to be heated by glow discharge. artifact.

Embodiment 2

[0016] Example 2: On the basis of Example 1, when the workpiece is heated to 400°C, both the cylinder and the workbench are connected to the negative pole of the DC power supply, and the cylinder and the workpiece simultaneously generate glow discharge and are heated , when the workpiece is heated to 520 ° C, it begins to enter the heat preservation stage of ion nitriding. After ion nitriding at this temperature for 1 hour, the space temperature in the cylinder is 510°C, which is close to the actual temperature of the workpiece, and is about 100°C higher than the space temperature without glow discharge auxiliary heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com