Forced cooling type radial flux permanent magnet synchronous motor based on plate winding

A permanent magnet synchronous motor, radial magnetic flux technology, applied in the shape/style/structure of winding conductors, synchronous machine parts, windings, etc., can solve the problem of low winding full slot ratio, short service life, poor heat dissipation effect, etc. problems, to achieve the effect of low overall cost, reduced volume and weight, and good air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

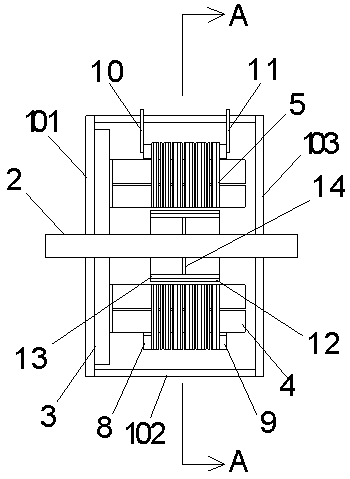

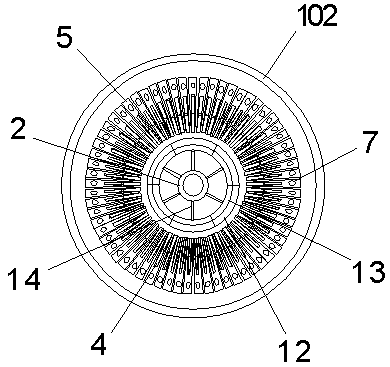

[0026] Example: see Figure 1 to Figure 4 , a forced cooling radial flux permanent magnet synchronous motor based on plate windings, including a motor housing, a motor shaft 2 and several windings. The motor housing includes a left end cover 101, a cylindrical housing 102 and a right end cover 103 connected together, one end of the motor shaft 2 passes through the left end cover 101 and the right end cover 103 in sequence, and the shaft of the motor shaft 2 The center line coincides with the axis center line of the cylindrical housing 102, and is rotatably connected with the left end cover 101 and the right end cover 103 through bearings. A connection plate 3 is arranged inside the left end cover 101 or the right end cover 103, and one side of the connection plate 3 is fixedly connected with the left end cover 101 or the right end cover 103 by bolts; The longitudinal direction of the slot coincides with the radial direction of the cylindrical housing 102 .

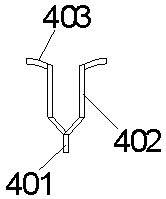

[0027] The windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com