Manufacturing method of fine insulated square wire

A manufacturing method and technology of square wires, applied in the direction of conductor/cable insulation, wire harness manufacturing, etc., can solve the problems of low volume utilization, increased gap, weak paint film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

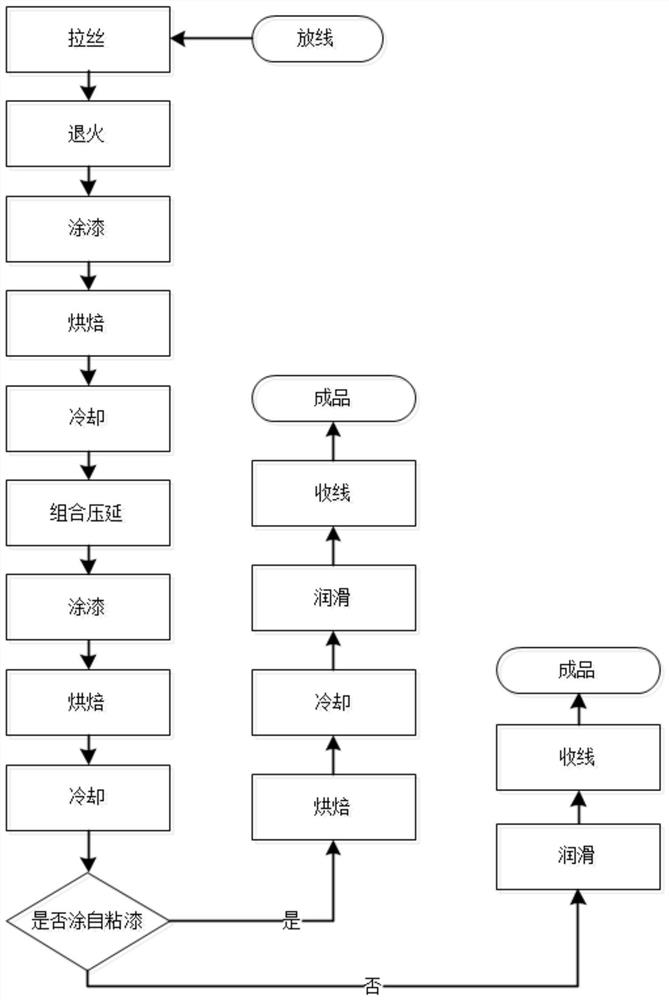

[0025] see figure 1 , figure 1 It is a flowchart of a method for manufacturing a fine insulated square wire according to the present invention. The invention discloses a method for making a fine insulated square wire, which comprises the following steps:

[0026] Step 1: pay off the conductor wire from the iron shaft at a constant speed, and the pay-off can be performed by a combined wire drawing machine. According to the requirements of product specifications, the semi-finished metal material is drawn into a round wire of a specific size by wire drawing. The metal material is copper, silver, aluminum, alloy, copper-clad aluminum or tinned copper and other conductive materials. The above-mentioned conductive materials are The most commonly used type on the market today, but not limited to the above-mentioned conductor materials.

[0027] Step 2: Perform high-temperature annealing on the wire, the high-temperature annealing temperature of the metal round wire is: copper: 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com