MEMS frequency partition matrix microphone sensor for environment noise monitoring

A microphone sensor and frequency partitioning technology, applied in the field of sensors, can solve problems such as signal distortion, brush selection, and sound frequency without a resonant cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

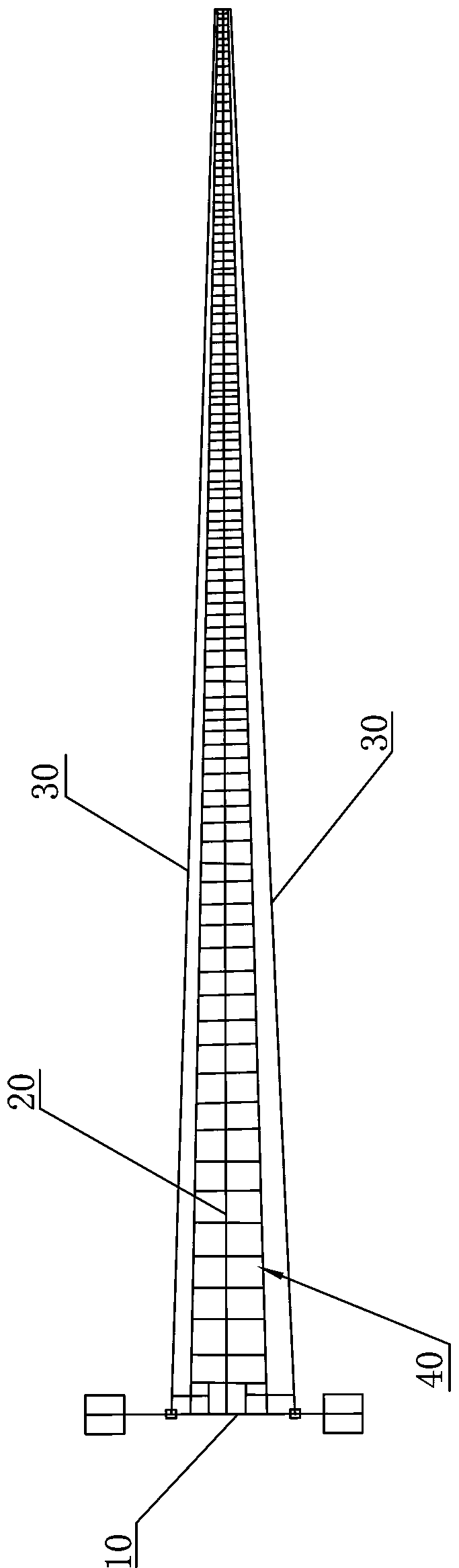

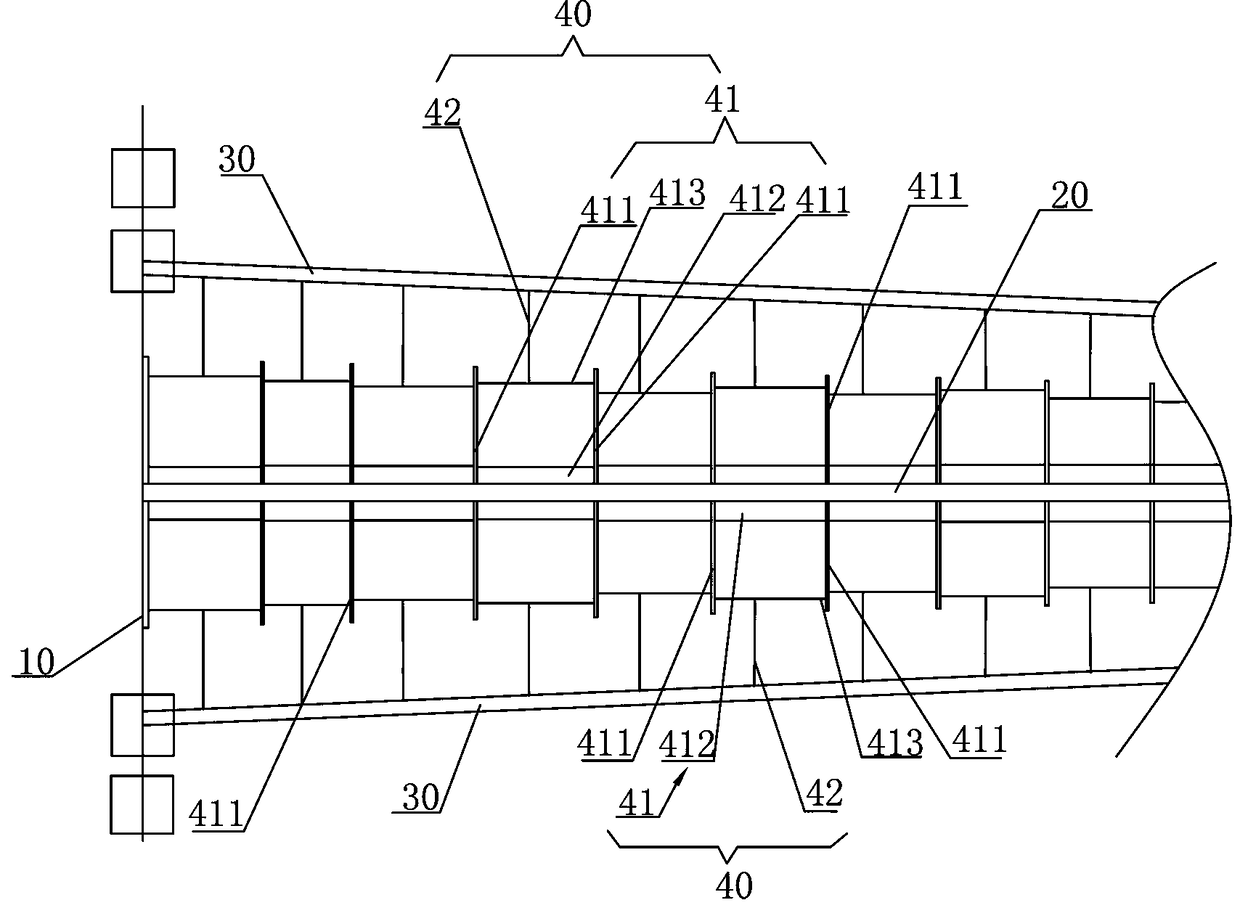

[0015] Figure 1 to Figure 2 , which is a preferred embodiment of a MEMS frequency partition matrix microphone sensor for complex environmental noise monitoring provided by the present invention. Such as Figure 1 to Figure 2 As shown, the MEMS frequency partition matrix microphone sensor for environmental noise monitoring includes an end substrate 10 and a flexible substrate 20 connected at one end to the end substrate, and the two sides of the flexible substrate 20 are respectively provided with sensor coatings for contacting sound traveling waves in liquids 30. Two or more resonant units 40 are provided between the two sides of the flexible substrate 20 and the corresponding sensor envelope 30 to convert the vibration of sound traveling waves into electric charges for the flexible substrate 20. The flexible substrate 20 can acquire var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com