Multi-microgravity louver baffling composite electric dust precipitator

An electrostatic precipitator and microgravity technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of low dust removal efficiency, increase of capture distance, increase of electric field strength, etc., to increase floor space and improve dust removal Efficiency, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

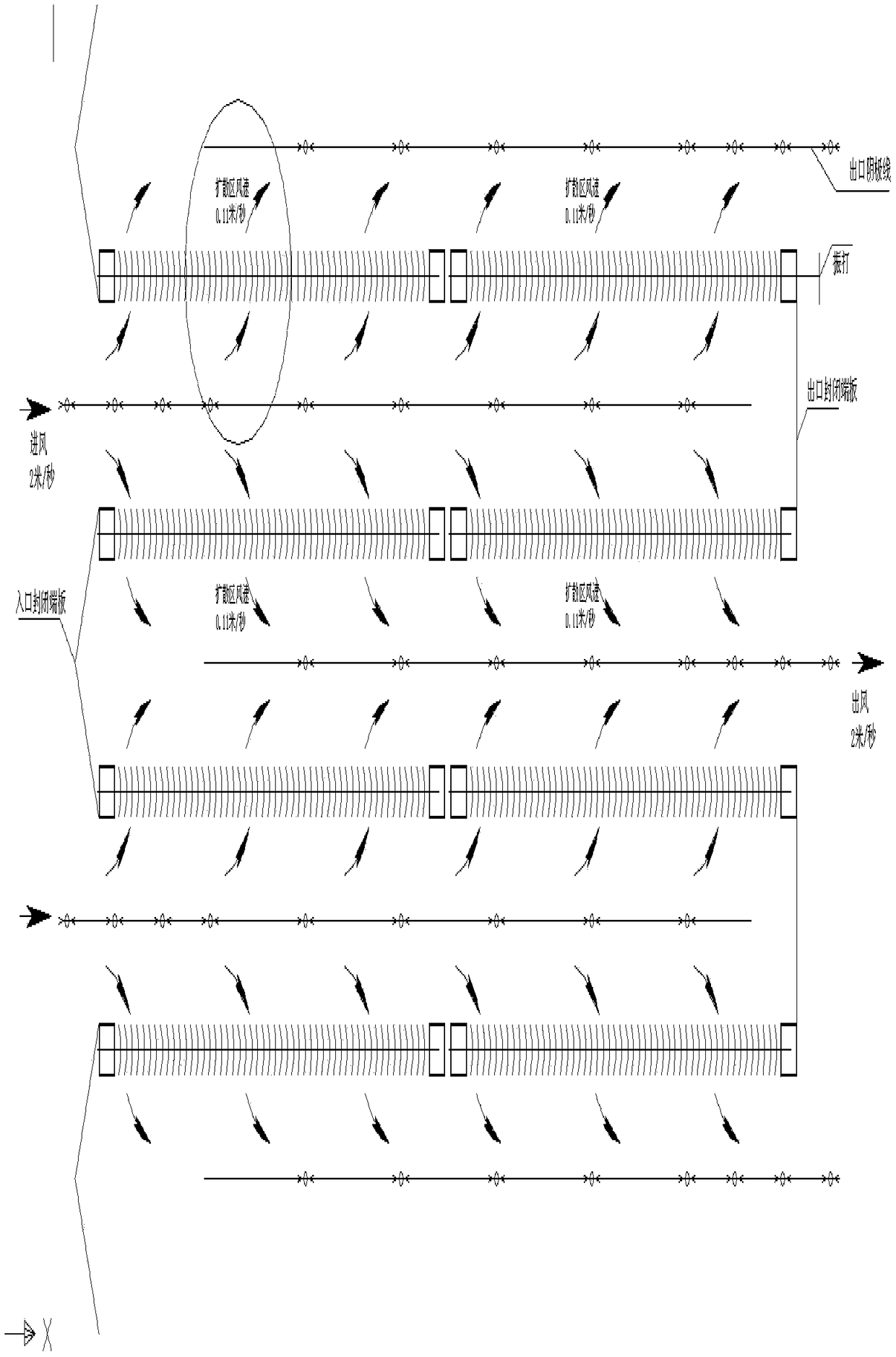

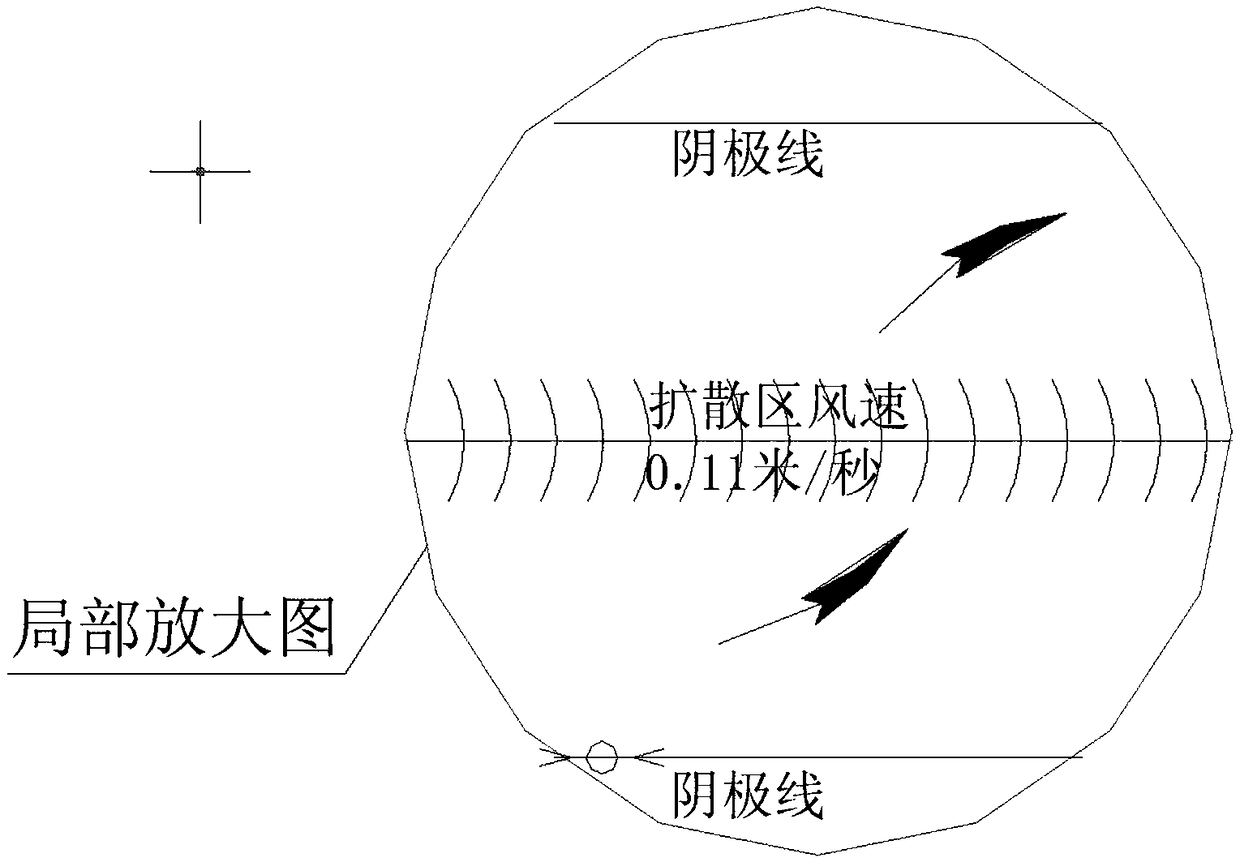

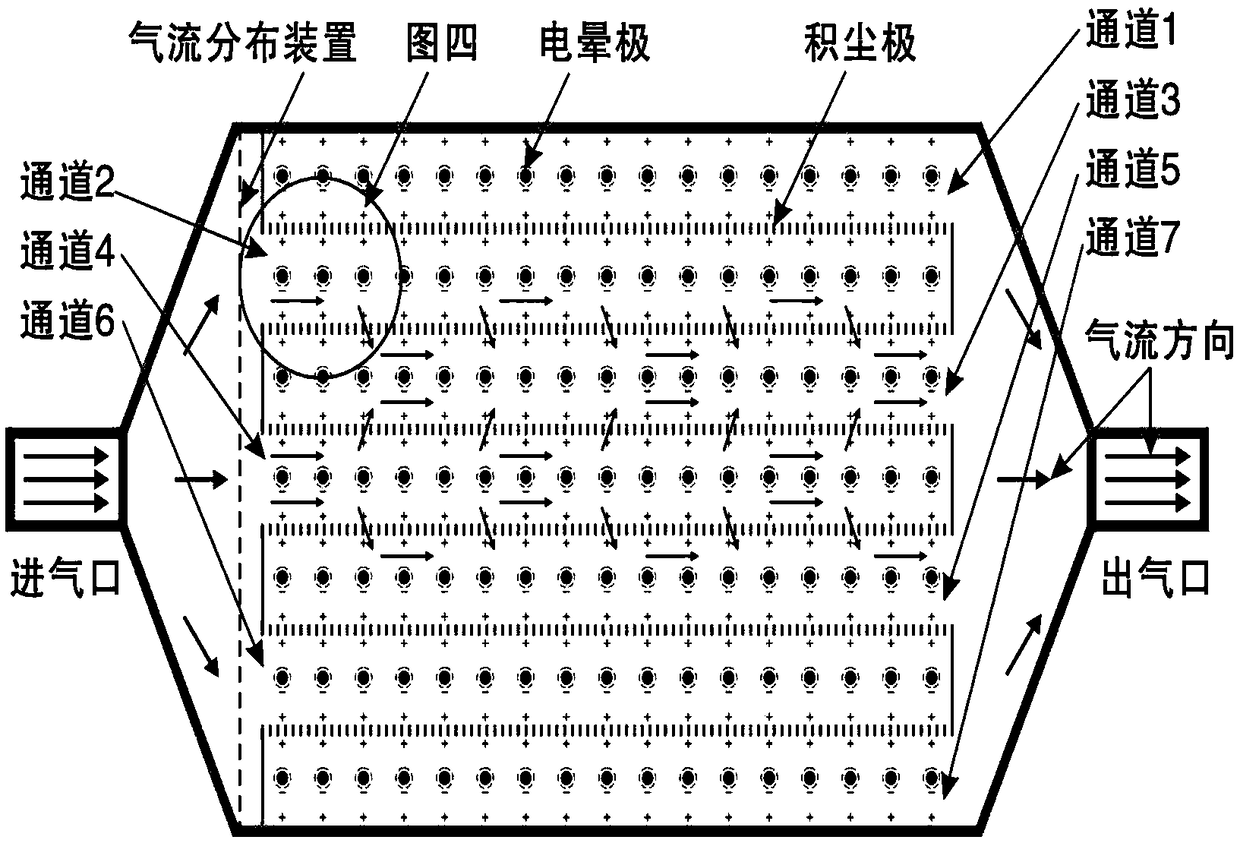

[0051] This embodiment provides a multi-element microgravity louver baffle composite electrostatic precipitator, which includes a square casing, with an air inlet and an air outlet at both ends of the casing, and multiple rows of dust accumulation electrodes are arranged inside the casing. The dust accumulation pole includes a dust accumulation frame and a transparent dust accumulation plate. The dust accumulation plate is arranged in the dust accumulation frame evenly in the axial direction. Between two adjacent dust accumulation poles, the outer dust accumulation pole and the inner wall of the corresponding side shell Airflow channels are formed between them, and baffles are respectively set at the air inlet ends of the odd-numbered sequence airflow channels and the outlet ends of the even-numbered sequence airflow channels. The pole is composed of a pole and a pole needle fixed on the pole, each corona pole is connected by a cathode line, and each pole needle is in a suspend...

Embodiment 2

[0057] This embodiment provides a multi-element microgravity louver baffle composite electrostatic precipitator. The structure of the electrostatic precipitator is the same as that of Embodiment 1, the only difference being that the width of the air flow channel in this embodiment is 380mm, and the blade inclination angle is 95°, which is equivalent to The distance between two adjacent blades is 25mm, the blade width is 45mm, and the blade length is 430mm.

[0058] The electrostatic precipitator provided in this embodiment can effectively reduce secondary dust and achieve a better dust removal effect.

Embodiment 3

[0060] This embodiment provides a multi-element microgravity louver baffle composite electrostatic precipitator. The structure of the electrostatic precipitator is the same as that of Embodiment 1, the only difference is that the width of the airflow channel in this embodiment is 420 mm, and the blade inclination angle is 105°, which is equivalent to The distance between two adjacent blades is 35mm, the blade width is 55mm, and the blade length is 530mm.

[0061] The electrostatic precipitator provided in this embodiment can also reduce secondary dust and achieve a better dust removal effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bevel angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com