Device and method for installing wooden supporting rod into linkage rod

A technology of linkage rods and wooden rods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as fracture and uneven force on the supporting rod, and achieve the effect of avoiding fracture, improving efficiency and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

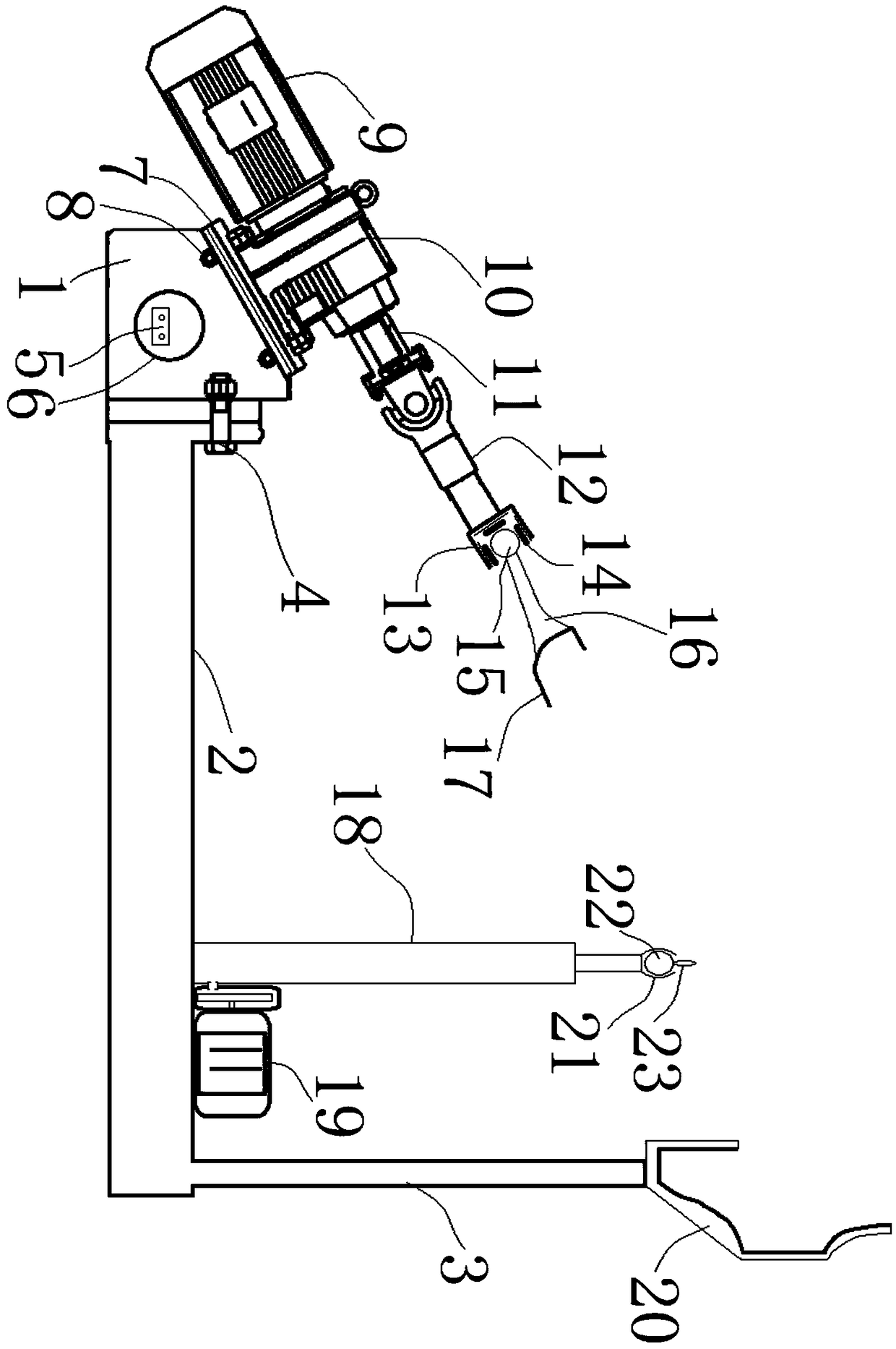

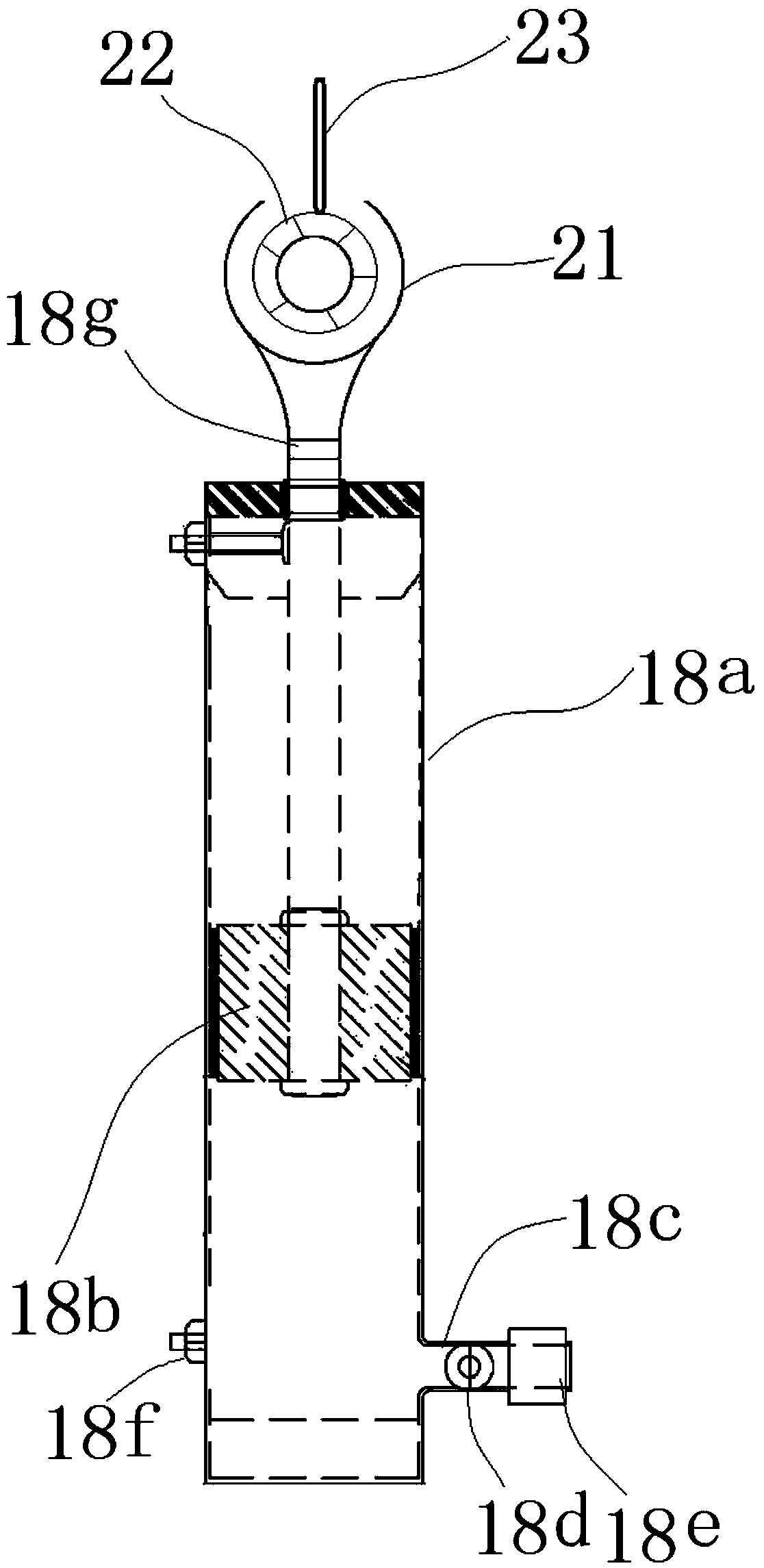

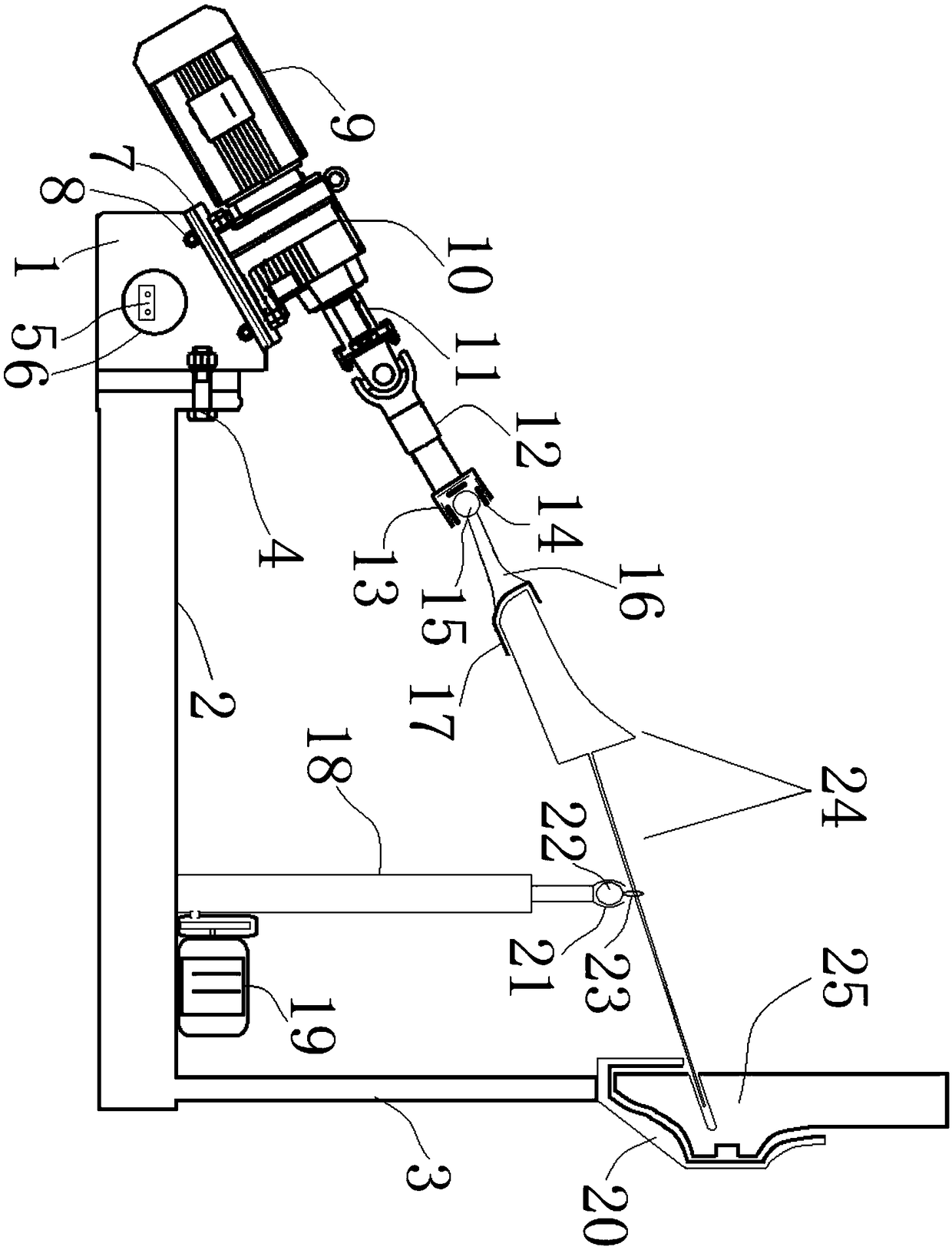

[0042] exist figure 1 In the shown embodiment, the device of the present invention includes a control box 1, a base 2, a support frame 3, a position adjustment member 4, a power interface 5, a main electric board 6, a steering motor 7, a coupling 8, a power motor 9, Gearbox 10, spin anchor rod 11, shaft extension rod 12, joint rod sleeve 13, pressure sensor 14, joint rod end 15, joint rod 16, bracket clamp 17, pneumatic lifting assembly 18, pump motor 19 , link clamping member 20, orientation ball sleeve 21, orientation ball 22, orientation ring 23. One end of the base 2 is connected to the control box 1 through the position adjustment member 4, the other end of the base 2 is vertically provided with a support frame 3 and a link clamp 20 is arranged on the top of the support frame 3, and the inside of the link clamp 20 is chiseled. It is empty and the shape of the gouging groove matches the outer peripheral shape of the end of the linkage rod; the main circuit board 6 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com