Variable form combination locknut

A technology for locking nuts and nuts, applied in the directions of nuts, screws, bolts, etc., can solve problems such as affecting the service life of bolts, and achieve the effects of improving service life, avoiding shearing, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

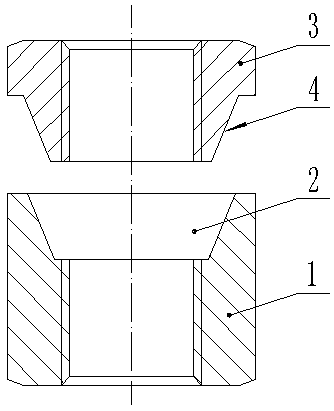

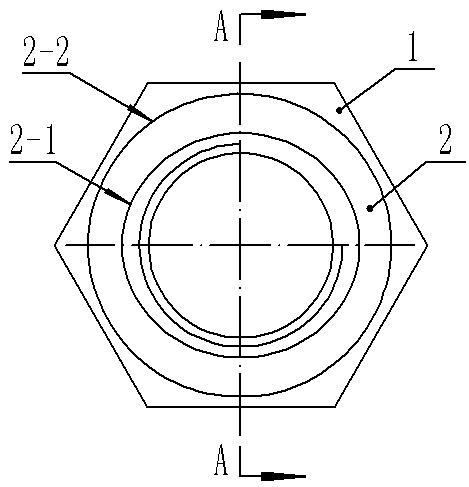

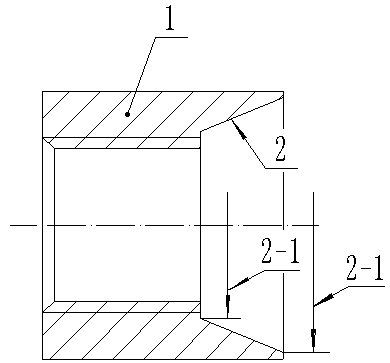

[0021] Example 1, such as Figure 1-7 As shown: the upper end surface of the female nut 1 is provided with an inverted conical counterbore 2 coaxial with its thread, and the lower end surface of the male nut 3 has an inverted conical platform 4 connected with it and coaxial with its thread . The surface of the inverted conical counterbore 2 is an inner conical structure, and the inverted conical frustum 4 is an inverted elliptical frustum structure. Wherein, the minor axis of the platform bottom surface 4-1 of the inverted conical platform body 4 is equal to the diameter of the hole bottom 2-1 of the inverted conical counterbore 2, and the minor axis of the platform top surface 4-2 is equal to the diameter of the inverted conical counterbore 2. Hole top mouth 2-2 diameter.

[0022] working principle

[0023] When the two nuts are tightened, since the wall thickness at the bottom of the hole 2-1 is far greater than the wall thickness at the bottom of the platform 4-1, the pl...

Embodiment 2

[0024] Example 2, such as Figure 1-7 As shown, on the basis that the basic structure is the same as that of Embodiment 1, the structure of the present invention can also be changed as follows: the hole bottom opening 2-1 and the hole top opening 2-2 of the inverted tapered counterbore 2 are oval structure, the inverted conical platform body 4 is an inverted conical frustum structure; wherein, the major axis of the hole bottom opening 2-1 is equal to the diameter of the platform bottom surface 4-1 of the inverted conical platform body 4, and the major axis of the hole top opening 2-2 is equal to The diameter of the platform top surface 4-2 of the inverted conical platform body 4.

[0025] working principle

[0026] When the two nuts are tightened, because the wall thickness at the bottom of the hole 2-1 is far greater than the wall thickness at the bottom of the table 4-1, the bottom of the table 4-1 with a circular structure will be at the bottom of the hole 2-1 with an oval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com