Through hole annular strain measuring device in static crushing process

A hoop strain and static crushing technology, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of lack of effective measurement devices for through holes, etc., and achieve the effects of large measurement results, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

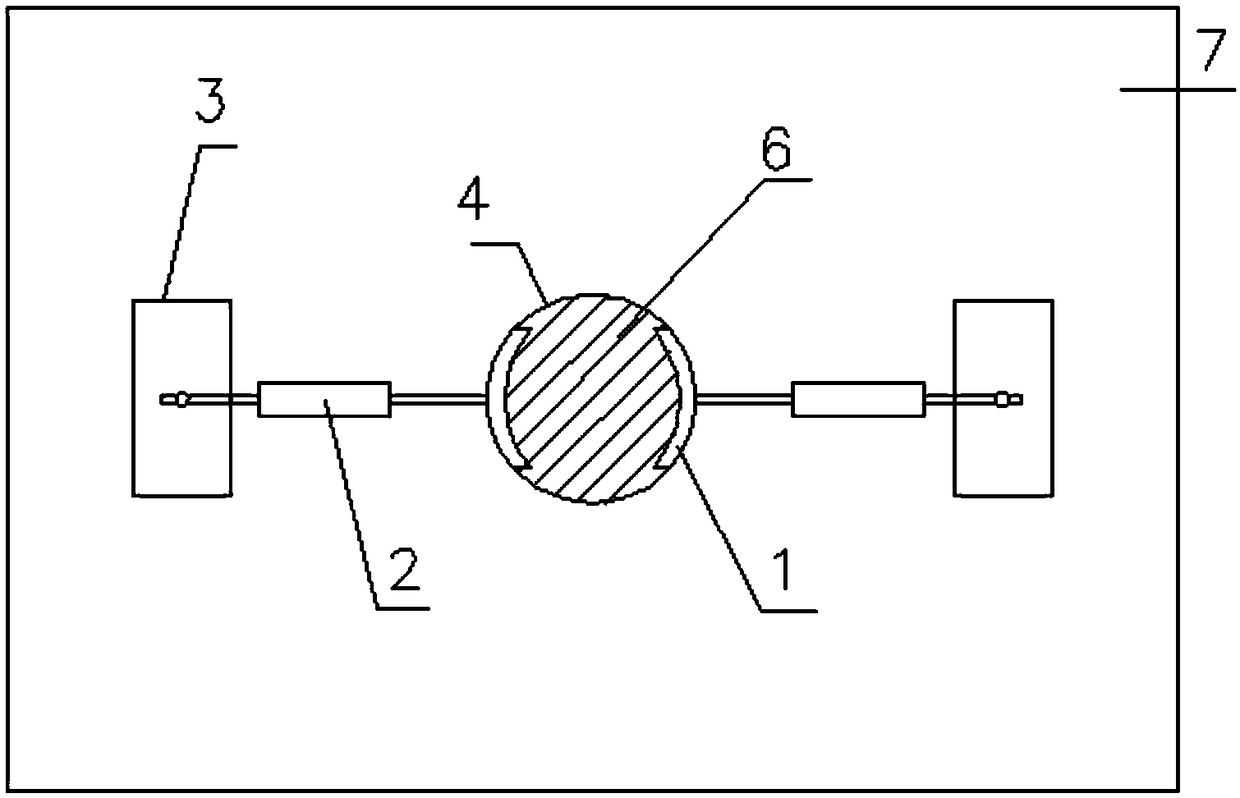

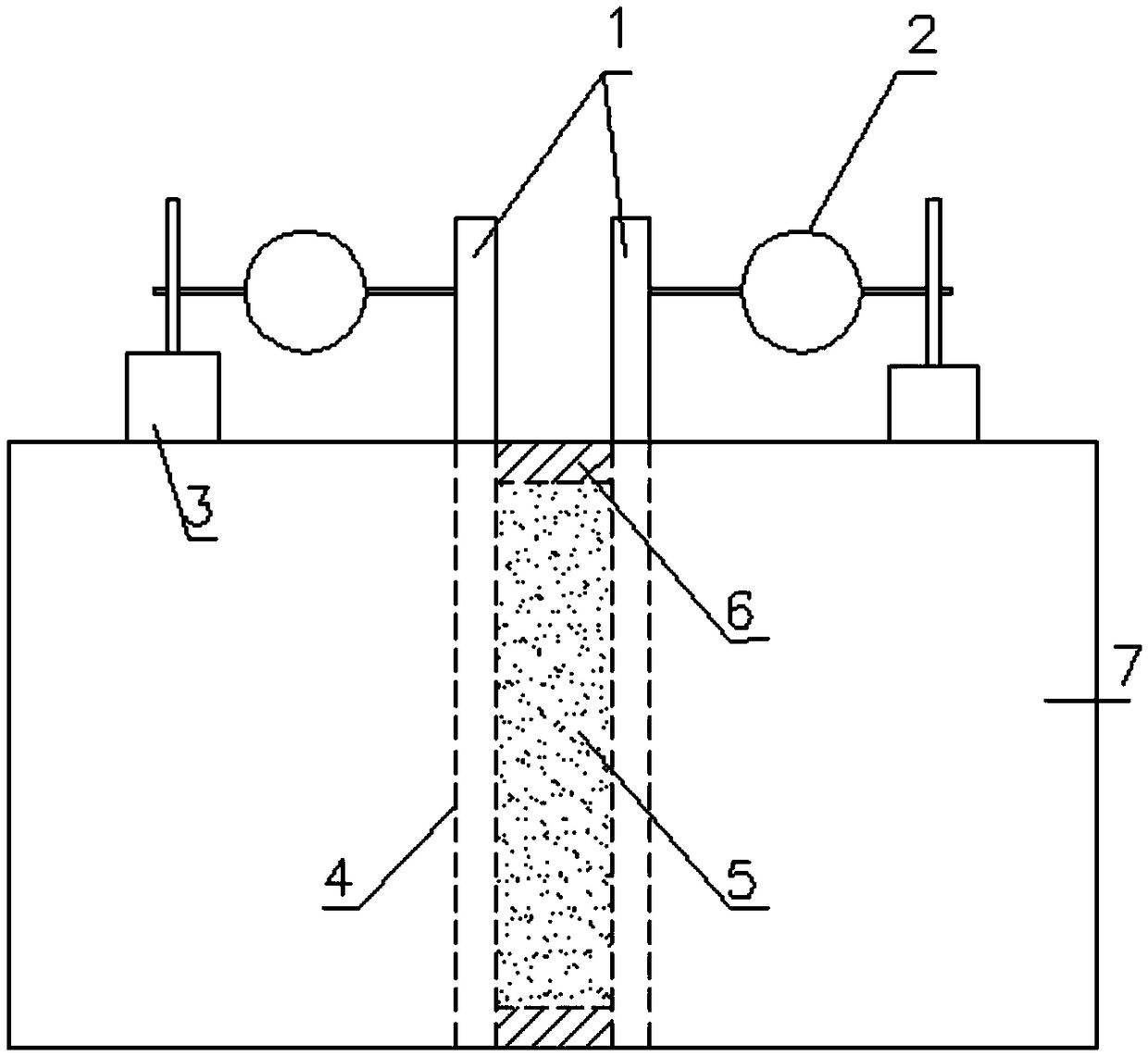

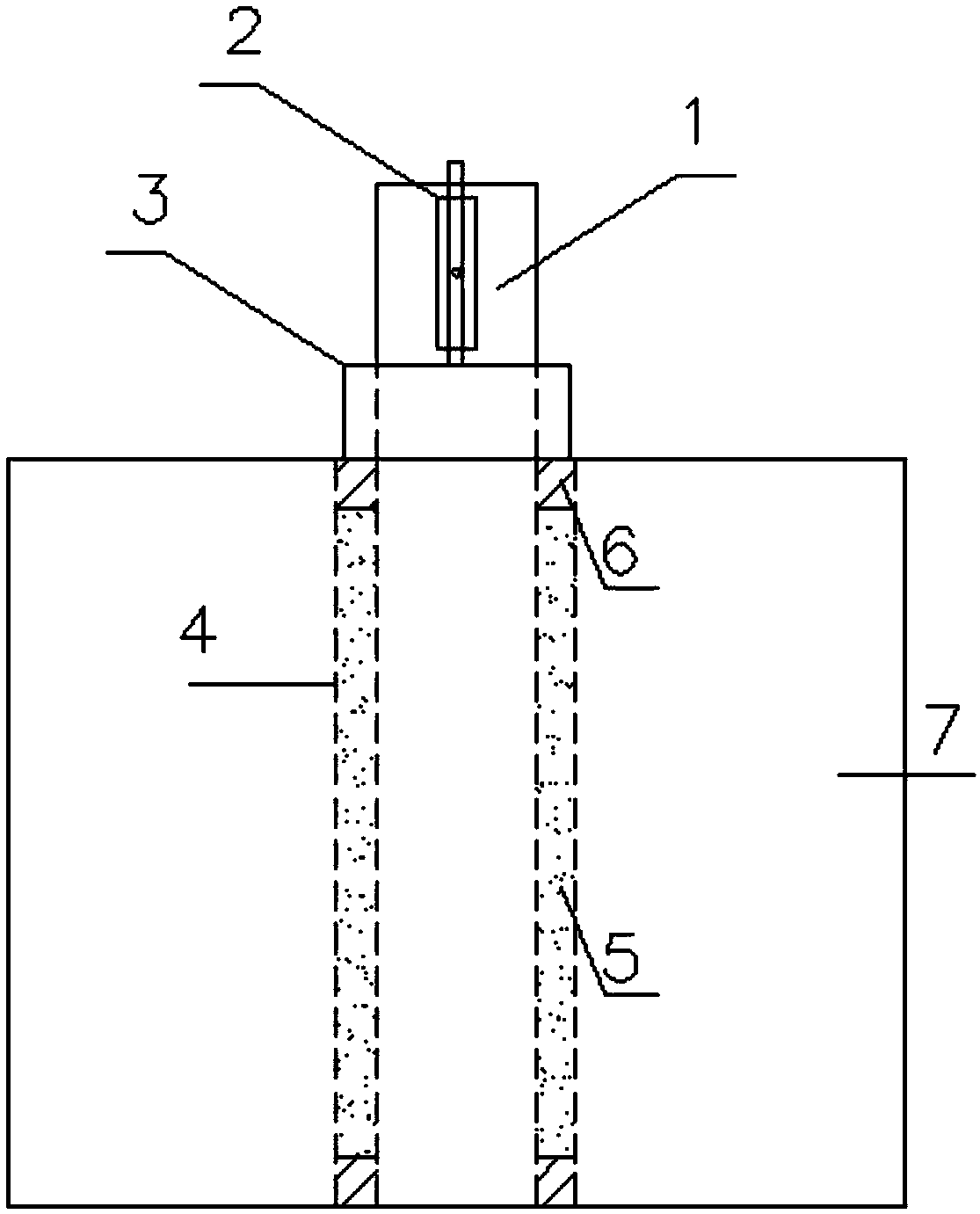

[0020] see Figure 1-4 Description of this embodiment, a measuring device for the circumferential strain of a through hole in a static crushing process, which includes a sensor and a metal sheet 1, the metal sheet 1 is arc-shaped, and the radius of the arc on the outer surface of the metal sheet 1 is the same as that of the blast hole 4 The radii are equal, the height of the metal sheet 1 is higher than the height of the blast hole 4, and the sensor includes a dial gauge 2 and a dial gauge base 3, and the dial gauge 2 is connected with the dial gauge base 3, and the dial gauge The base 3 contains magnets, and the circular arc convex surface 8 of the metal sheet 1 is closely bonded to the wall of the blast hole 4, so that the metal sheet 1 penetrates the blast hole 4, and the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com