Kerr microscope

A technology of objective lens and mirror, applied in the field of Kerr microscope, can solve the problems of complex magnetic domain magnetization direction, time-consuming and laborious operation, difficult to meet accuracy requirements, etc., and achieve the effect of reducing mechanical instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

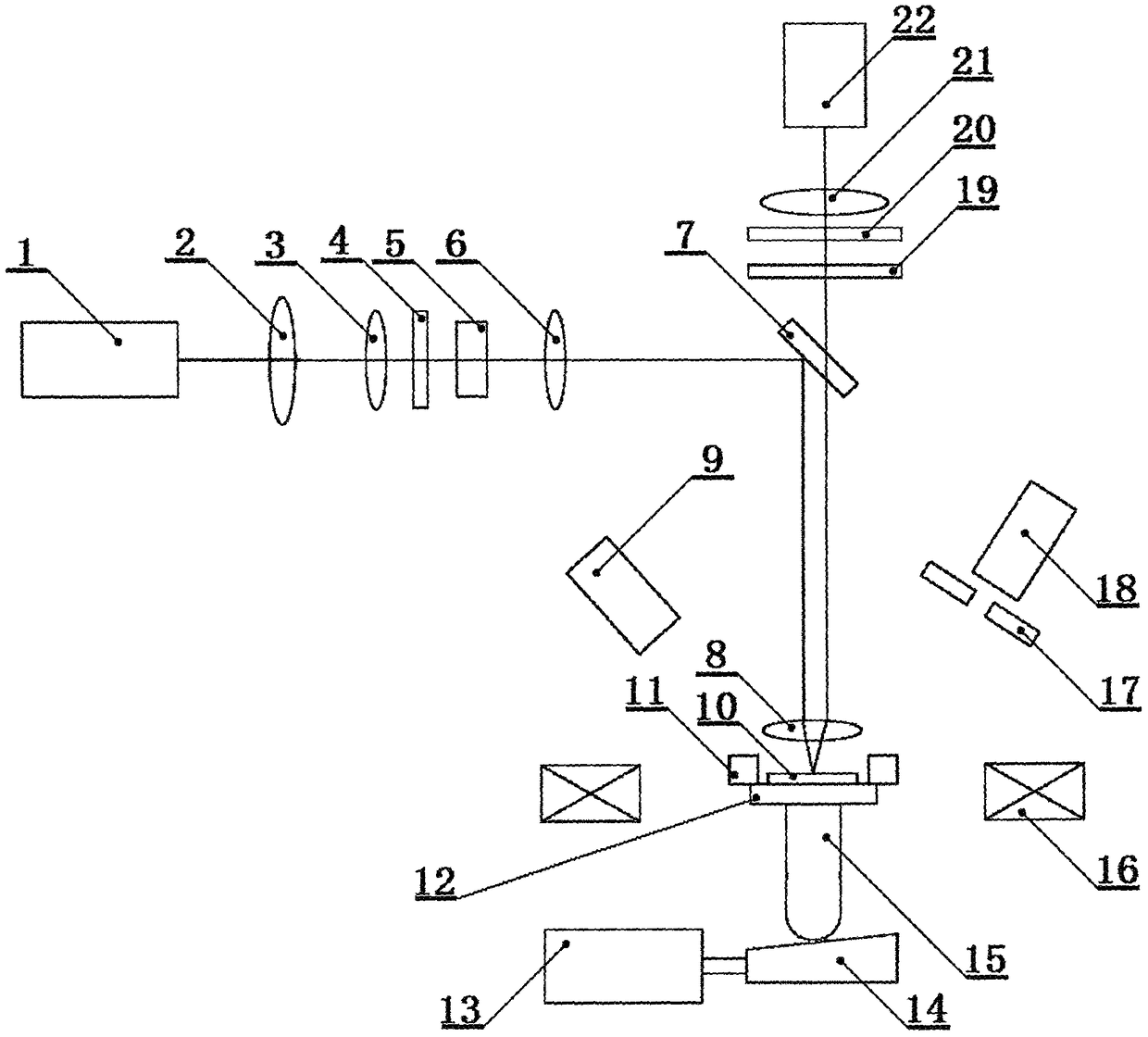

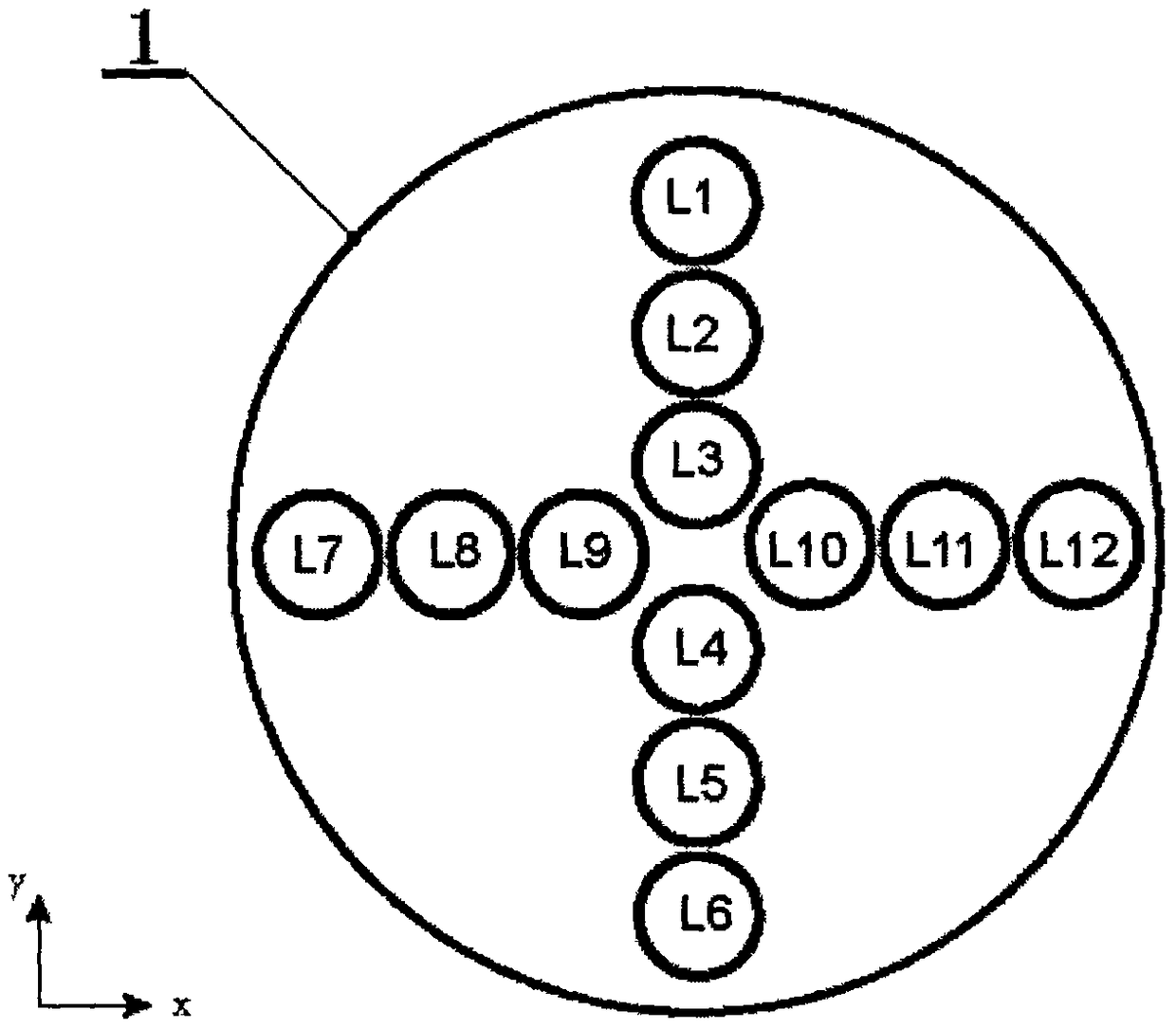

[0030] Such as figure 1 is a schematic diagram of the present invention, such as figure 2 It is an enlarged schematic diagram of the side of the light source. There is an xy two-dimensional direction mark in the lower left corner. Device 5, aspheric mirror III 6, semi-transparent mirror 7, objective lens 8, laser 9, sample 10, sample stage 11, substrate 12, stepper motor 13, bevel stage 14, thimble 15, magnet 16, slit diaphragm 17 , photodetector I18, compensator 19, analyzer 20, aspheric mirror IV21, photodetector II22, the light source 1, aspheric mirror I2, aspheric mirror II3, field stop 4, polarizer 5, aspheric mirror III6 , semi-transparent mirror 7, and objective lens 8 form an illumination optical path in turn, and described objective lens 8, semi-transparent mirror 7, compensator 19, analyzer 20, aspheric mirror IV21 form imaging optical path in turn, and described laser 9, sample 10 surface , slit diaphragm 17, and photodetector I18 form a calibration optical path...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com