Plastic liner with inner lining

A technology for internal containers and plastics, applied in containers, rigid containers, unloading devices, etc., can solve the problems of poor compression resistance and unusability of composite films, and achieve the effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

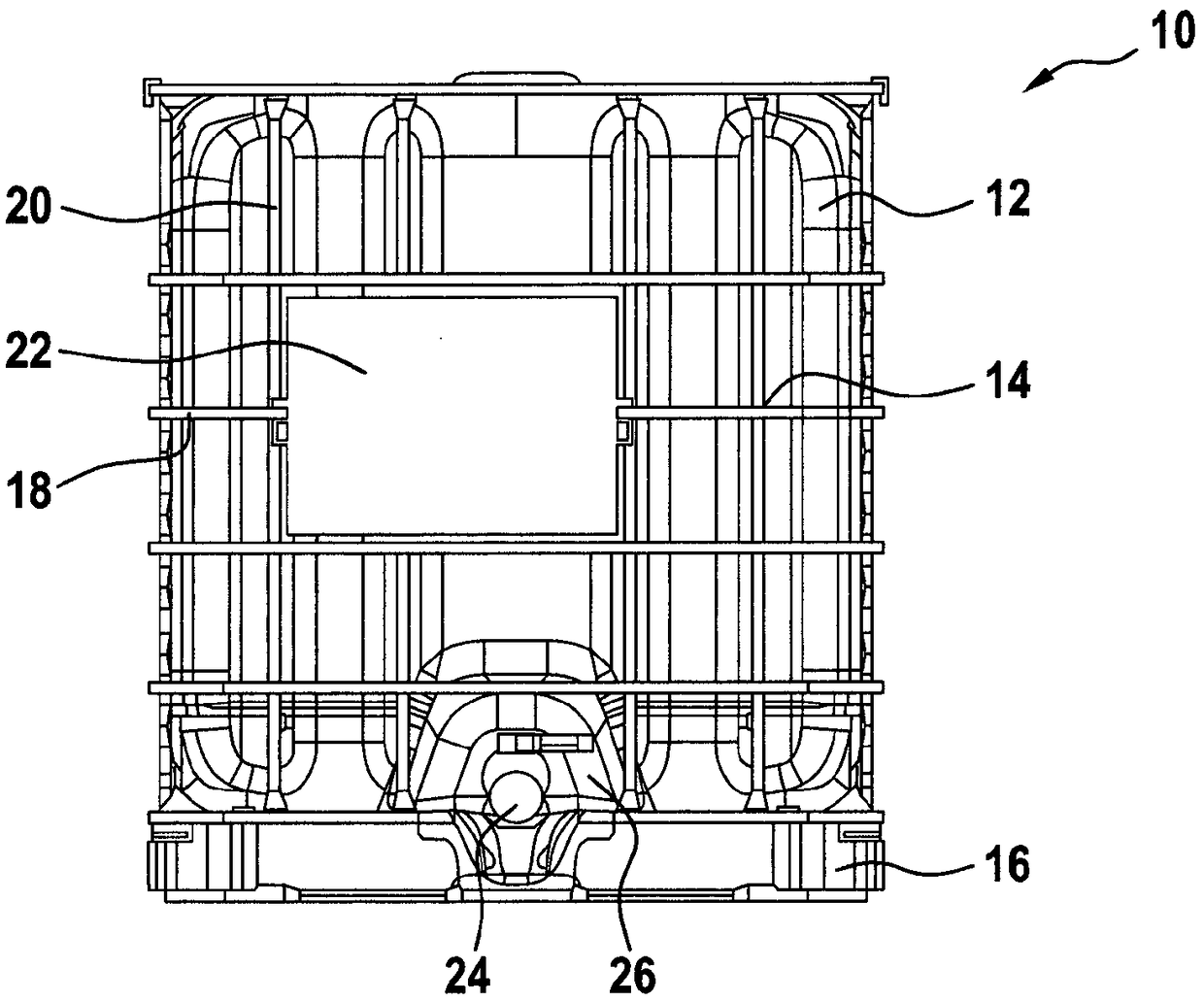

[0025] exist figure 1 The reference number 10 identifies a pallet storage box with a plastic inner container 12 according to the invention for storing and transporting in particular hazardous, liquid or flowable fillers. The pallet storage tank 10 meets special test criteria for the use or application of hazardous liquid fillings and has a corresponding official BAM approval (German Federal Institute for Materials Testing). In an embodiment with a fill volume of about 1000 L, the pallet storage tank 10 has standardized dimensions of about 1200 mm in length, about 1000 mm in width and about 1150 mm in height. However, IBCs with other sizes and smaller or larger charge volumes from 800 L to 1300 L are also commonly used.

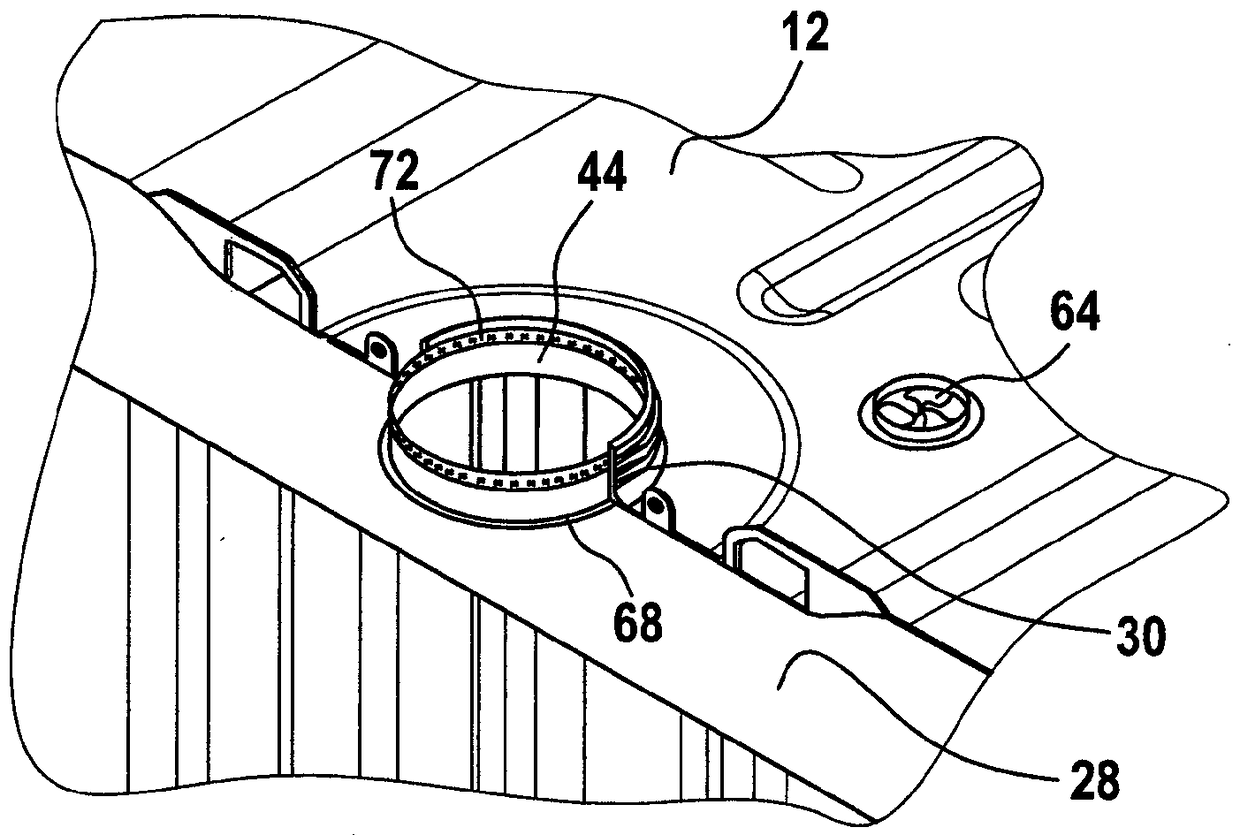

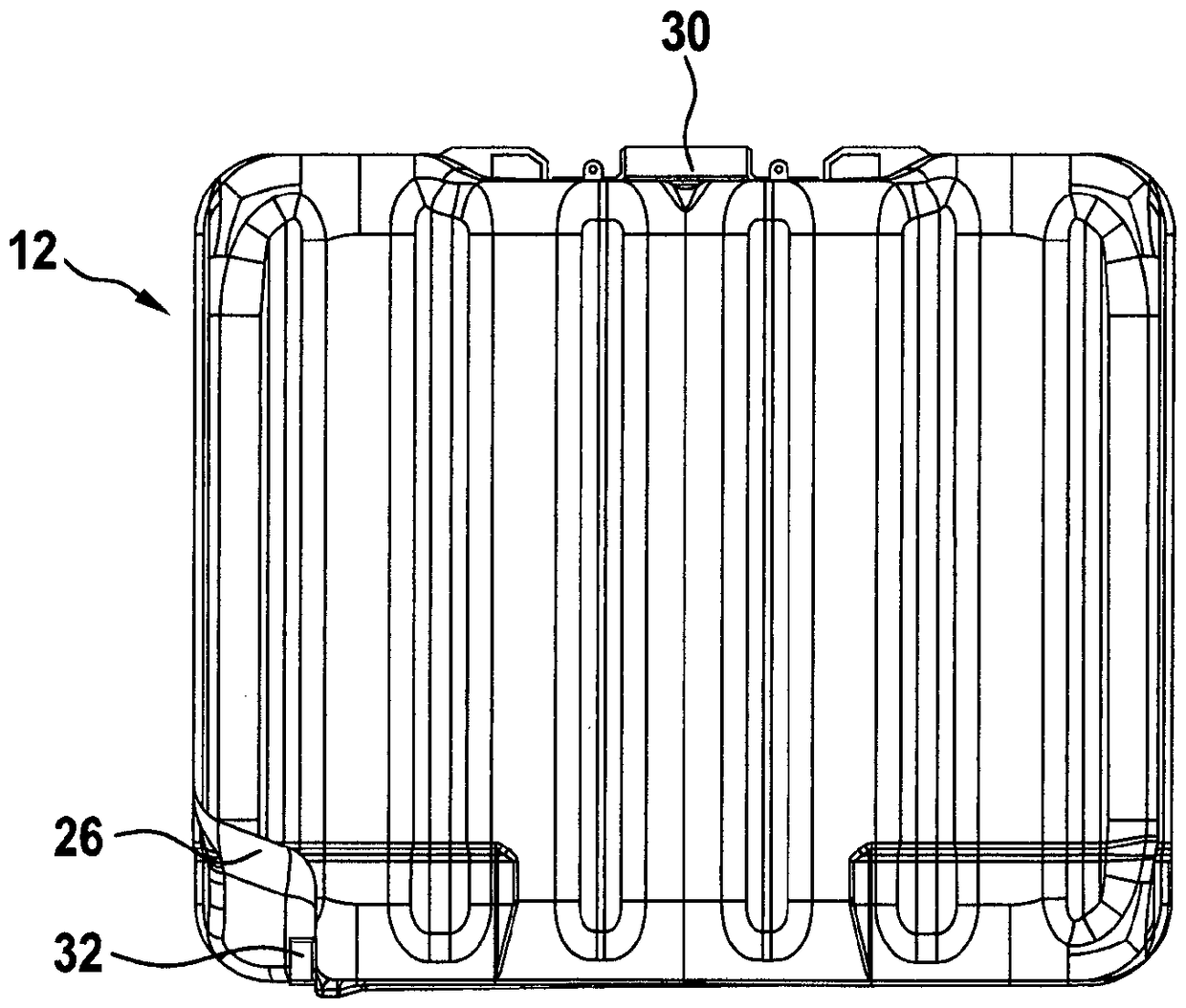

[0026] The main elements of the shown pallet storage tank 10 consist of a thin-walled rigid inner container 12 made of thermoplastic in a blow-molding process, a grid of tubes tightly surrounding the cuboidal plastic inner container 12 as a support hood The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com