Lossless detector and manufacturing method thereof

A detector, lossless technology, applied in the field of lossless detector and its manufacturing, can solve the problems of troublesome assembly operation, inability to reuse, increase production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

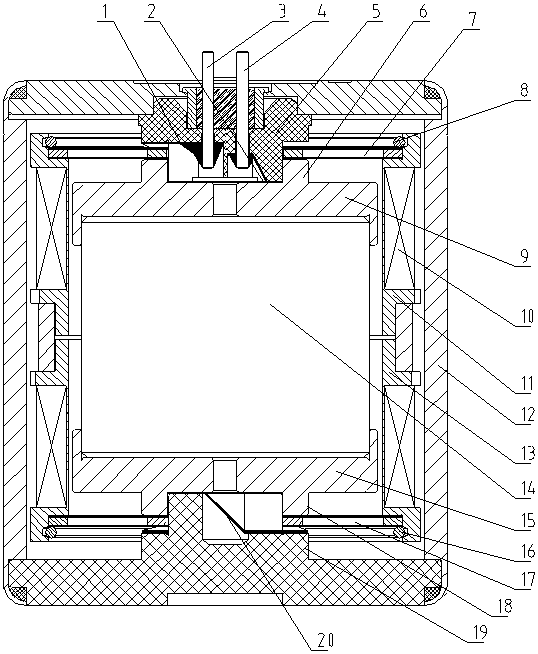

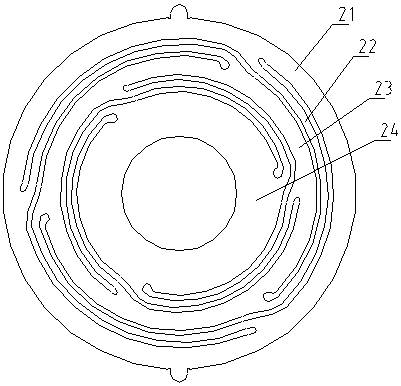

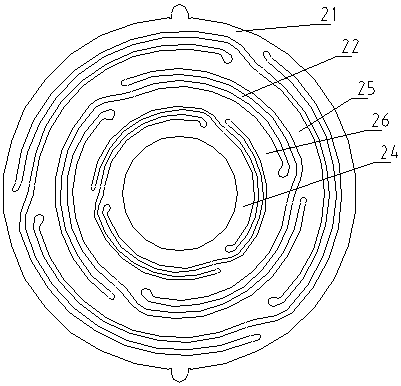

[0020] Such as figure 1 The lossless detector shown includes an outer shell 12, a magnetic steel 14 is arranged in the middle of the outer shell 12, an upper yoke 9 and a lower yoke 15 are respectively arranged on the upper and lower ends of the magnetic steel 14, and the upper middle of the upper yoke 9 is An upper spring piece 7 is fixed between the upper side of the outer shell, and the upper spring piece 7 is ring-shaped. The inner side of the annular upper spring piece is fixed between the upper end of the upper yoke and the outer shell. An insulating layer is provided between them; a lower spring piece 17 is fixed between the middle part of the lower end of the lower yoke 15 and the lower side of the outer casing, the lower spring piece 17 is ring-shaped, and the inner side of the ring of the lower spring piece 17 is fixed between the lower end of the lower yoke iron and the outer casing. There is an insulating layer between the spring piece, the lower yoke and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com