Aperture residue-lifting screw for causticizing slaking

A screw and digester technology, applied in the field of causticizing equipment, can solve the problems of loss of solution and waste, and achieve the effects of reducing material consumption, improving utilization rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

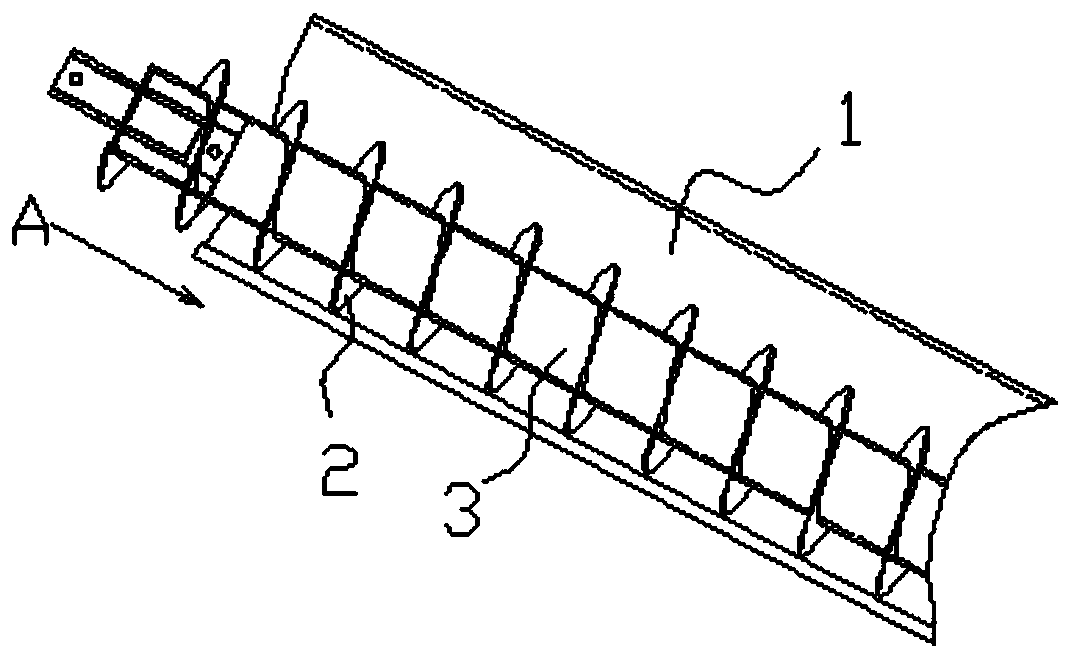

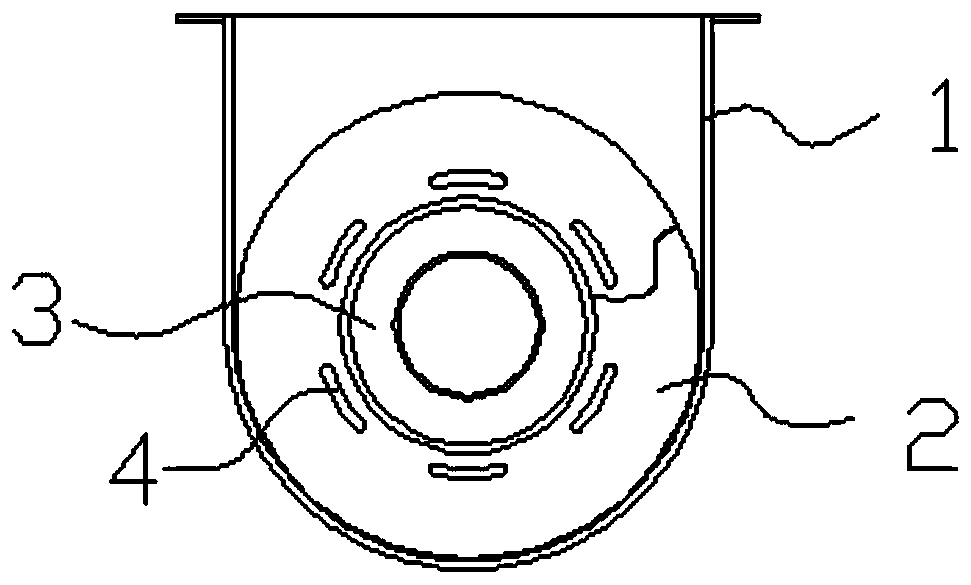

[0011] Embodiment 1: as attached Figure 1~2 As shown, a perforated slag extracting screw for causticization digestion includes a digester shell 1, a screw shaft 3 and a screw 2, and the digester shell 1 is a U-shaped structure arranged obliquely. The inner bottom of the casing 1 is provided with a screw shaft 3, on which a screw 2 is fixedly connected, and the screw 2 is provided with a plurality of discharge holes 4 along the circumferential direction.

[0012] Further, six discharge holes 4 are evenly arranged in a circumferential direction, and discharge holes 4 are arranged in the axial direction of the screw 2 .

[0013] Further, the discharge hole 4 is an arc-shaped oblong hole structure. The hole width is 5 mm, the hole length is 250 mm, arranged in an arc shape, with the screw shaft 3 as the center.

[0014] By opening the discharge hole 4 on the slag extraction screw 2, the solution can flow back into the digester through the discharge hole 4 during the slag extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com