Multipiece wiring board, wiring board, and method for manufacturing multipiece wiring board

A wiring substrate and multi-piece technology, which is applied in the manufacturing field of multi-piece wiring substrates, can solve the problem of small width of the dividing groove, and achieve the effects of suppressing burrs and chipping, high dimensional accuracy, and good dividing ease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

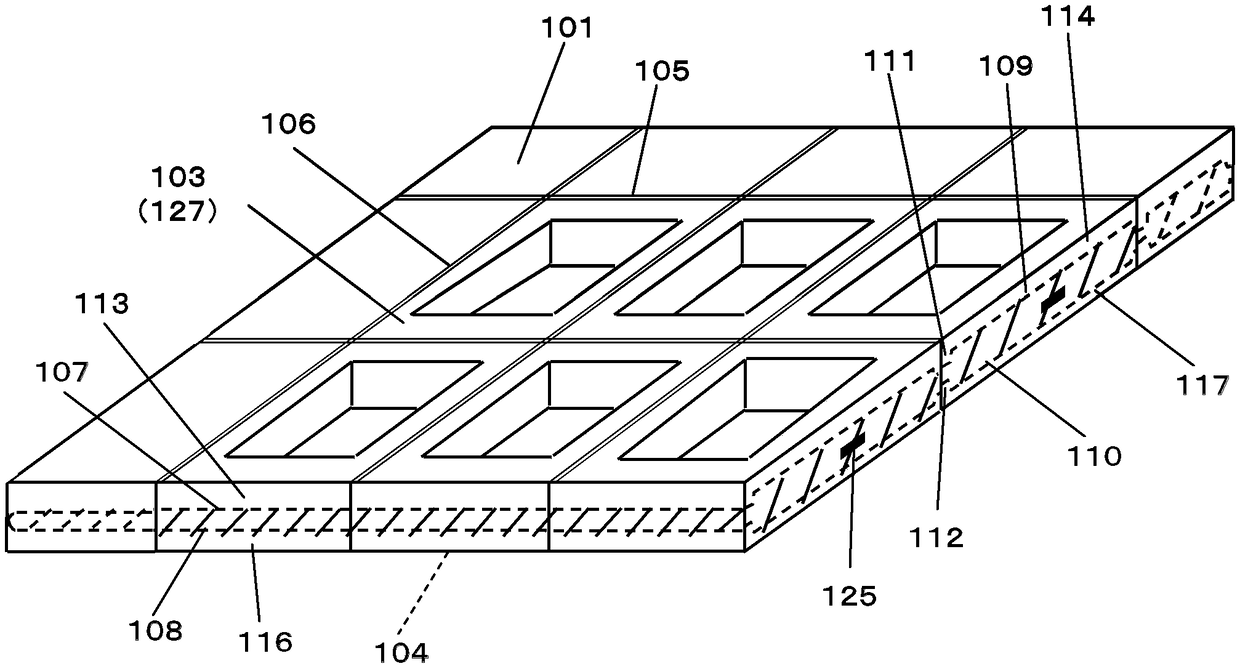

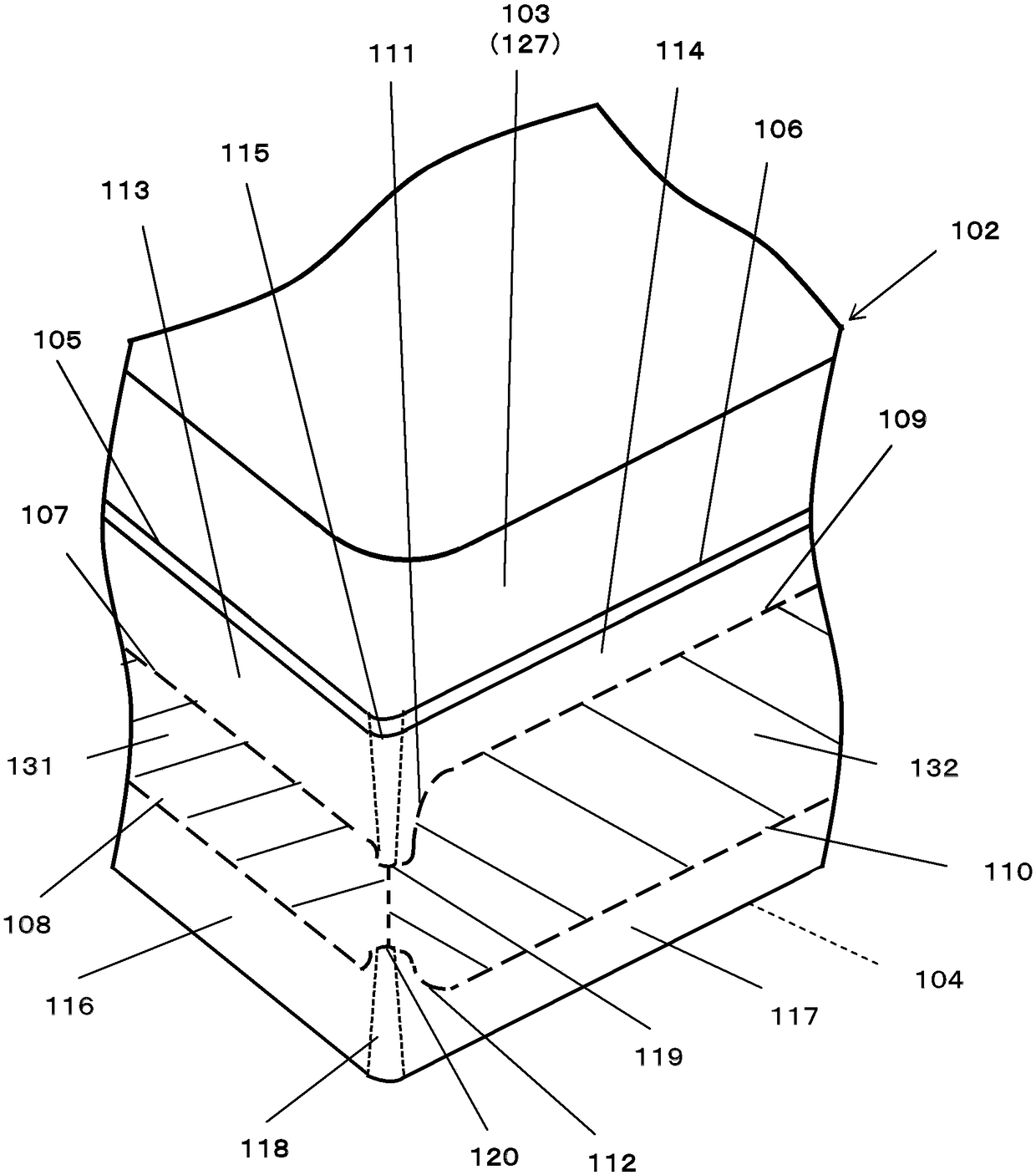

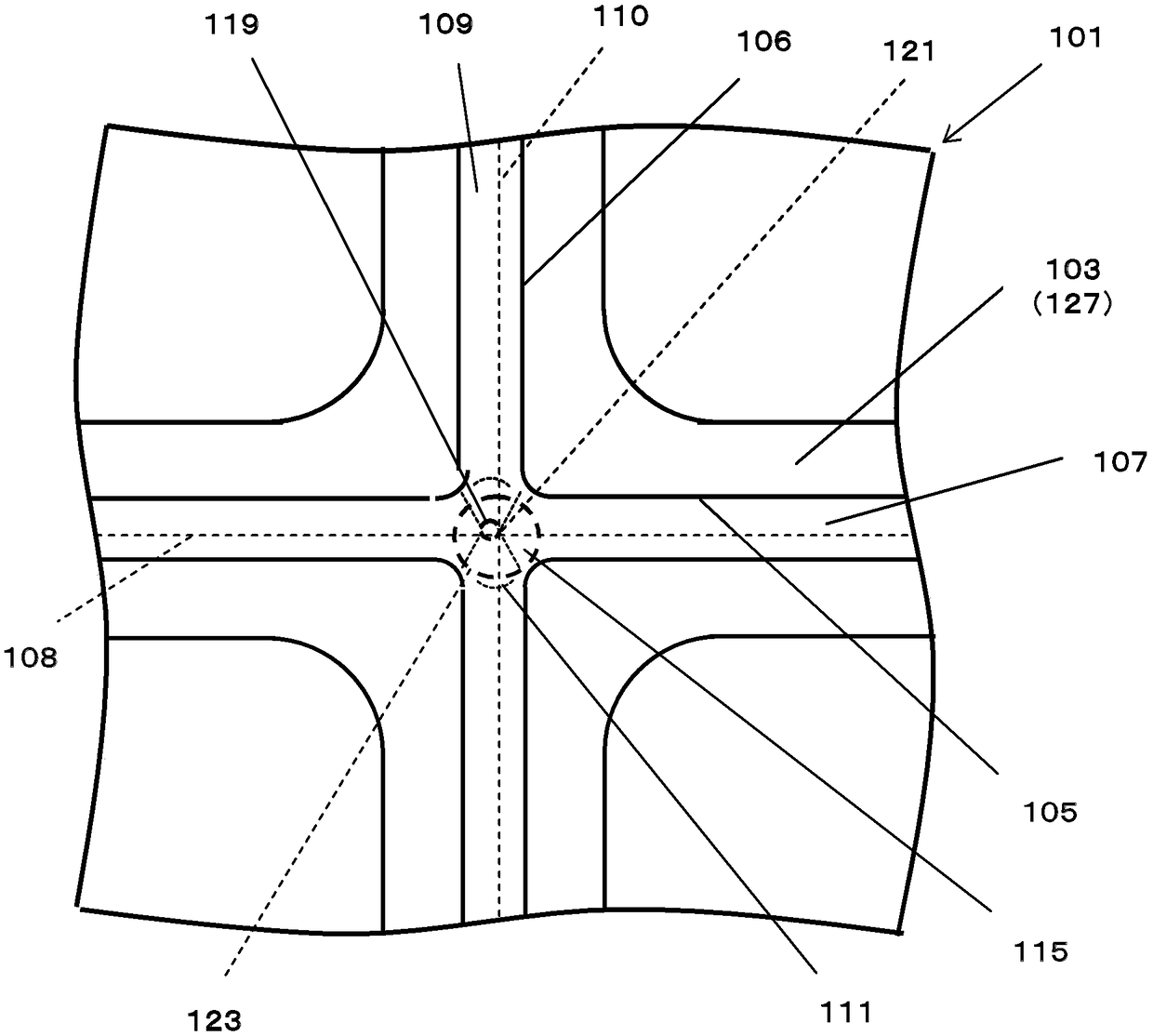

[0025] A multi-piece wiring board, a wiring board, and a method for manufacturing a multi-piece wiring board according to the present invention will be described with reference to the drawings.

[0026] exist Figure 1 to Figure 8 Among them, 101 is the motherboard, 102 is the wiring substrate, 103 is the first main surface, 104 is the second main surface, 105 is one side, 106 is the other side, 107 is the first dividing groove, 108 is the second Dividing groove, 109 is the third dividing groove, 110 is the fourth dividing groove, 111 is the first curved part, 112 is the second curved part, 113 is the first side, 114 is the second side, 115 is the first curved surface, 116 is the third side, 117 is the fourth side, 118 is the second curved surface, 119 is the first bottom, 120 is the second bottom, 121 is the first intersection, 122 is the second intersection, 123 is the first imaginary circle, 124 is a second imaginary circle, 125 is a wiring conductor for connection, 126 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com