Robot motion trajectory planning system, method and device

A robot movement and trajectory planning technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high staff requirements and low robot use efficiency, and achieve the effect of reducing technical requirements and shortening teaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

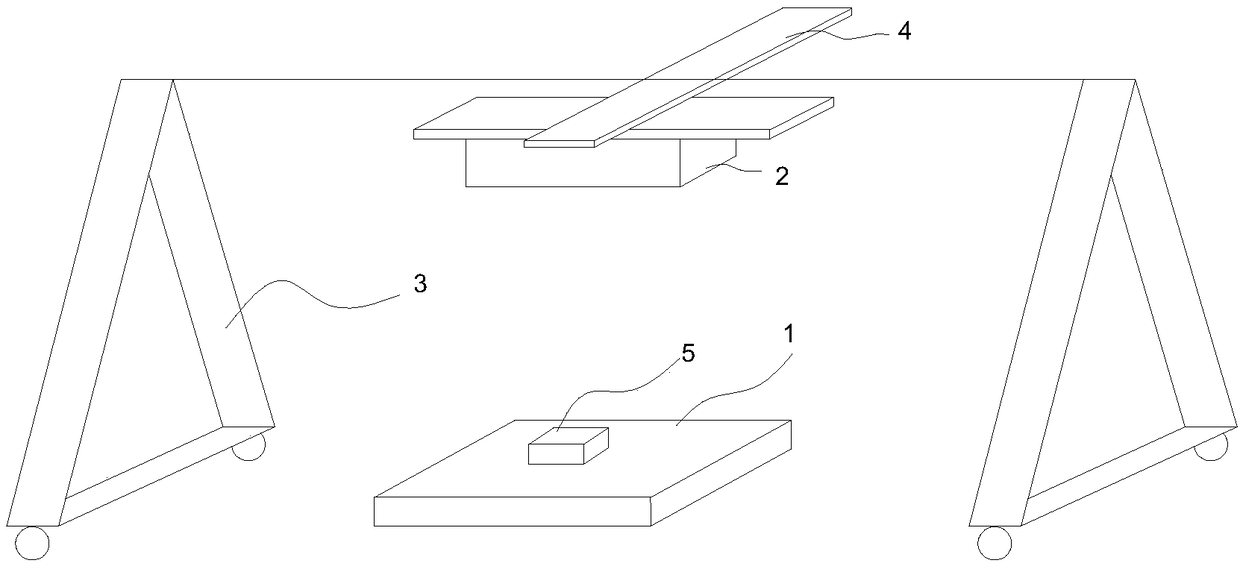

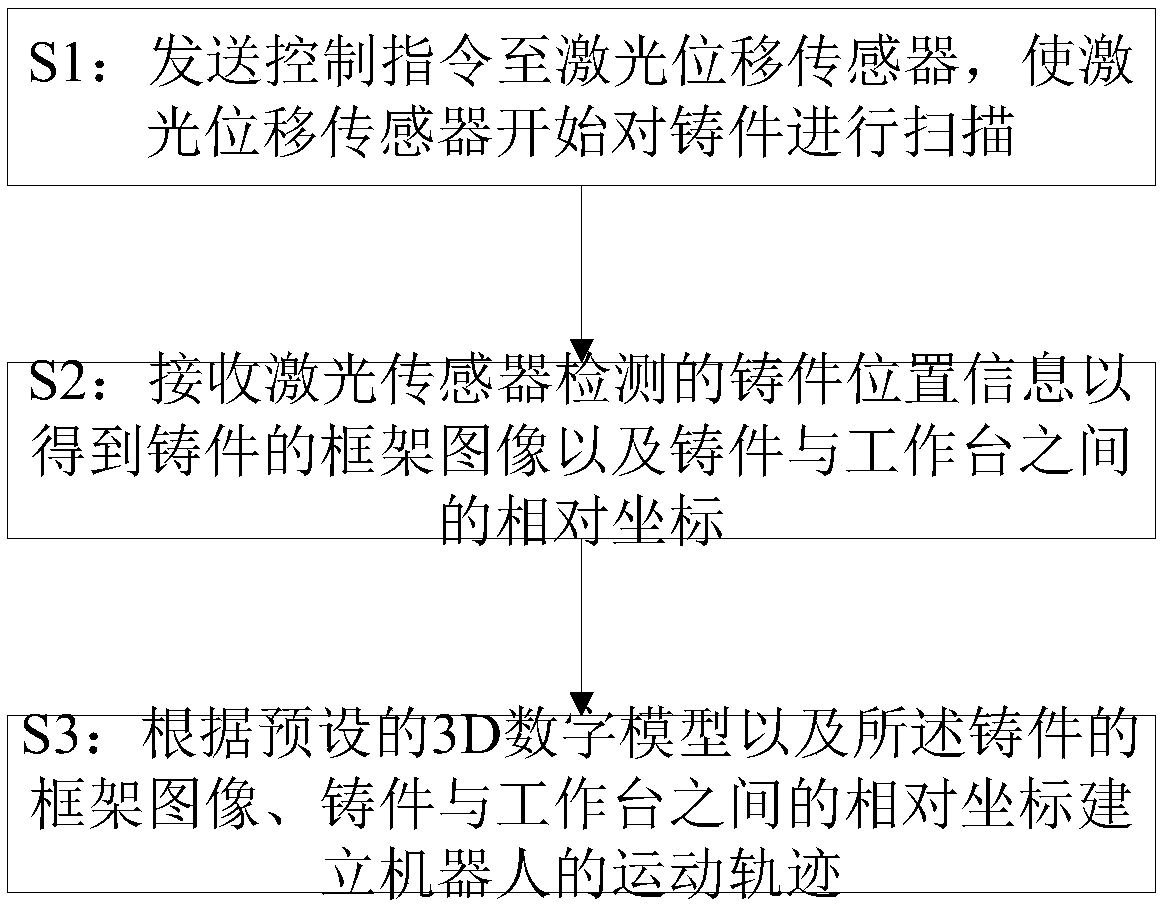

[0029] Such as figure 1 As shown, the present invention discloses a robot trajectory planning system. In order to solve the problems of time-consuming and inaccurate positioning of casting grinding robot trajectory planning, the system includes a workbench 1, a laser displacement sensor 2, a fixed frame 3 and a moving track 4. The moving track 4 is installed on the fixed frame 3, the laser displacement sensor 2 is installed on the moving track 4, the workbench 1 is used to hold the casting 5 to be scanned, the laser displacement sensor 2 is located above the casting 5, and the laser displacement sensor 2 is used to move along the X-axis and Y-axis under the drive of the moving rail 4, so as to scan the casting 5 right above to obtain the frame image of the casting 5.

[0030] In fact, the system of the present invention also includes a host computer, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com