Nonmetal frame machine

A non-metal and frame technology, applied in the field of non-metal frame machines, can solve the problems of low efficiency and inability to guarantee accuracy, and achieve the effects of high efficiency, excellent quality and reliable accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

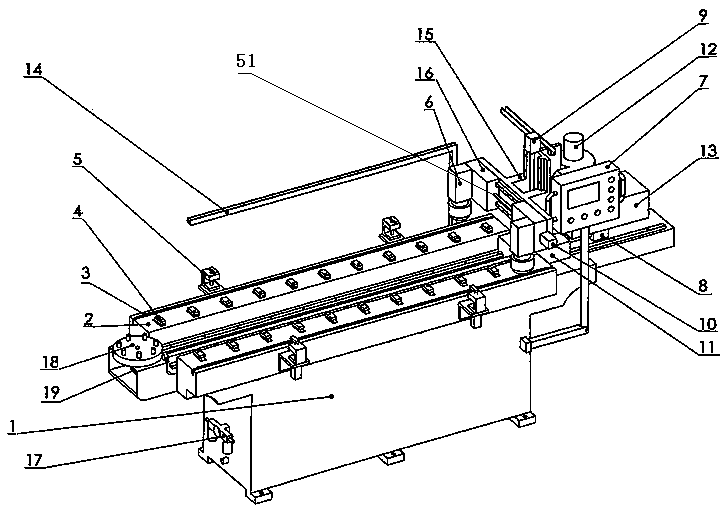

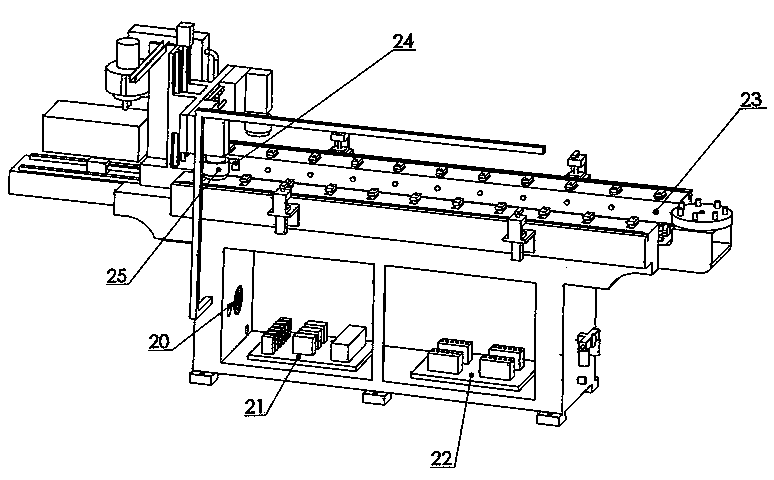

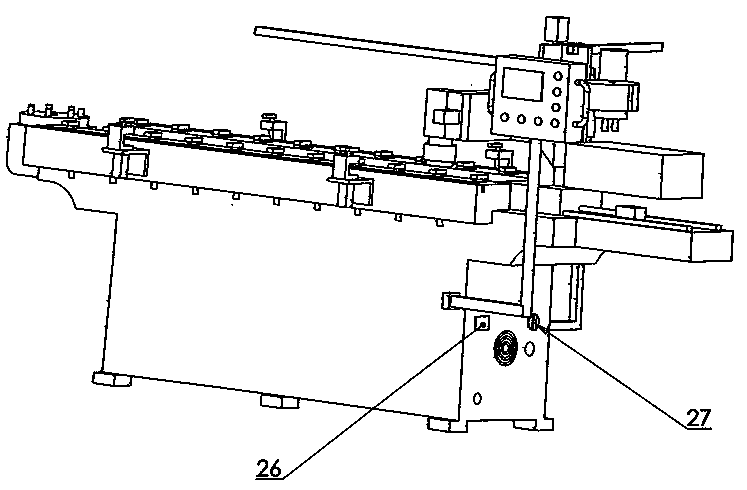

[0020] Example 1, see figure 1 , 2 , 3, 4, 6, 7, and 8, a non-metallic frame machine includes a bed 1 and a workbench 2 installed on the bed, and one end of the workbench 2 is equipped with a tool replacement turntable 18, and the tool Replace the rotary table 18 and the rotary table motor 19 shaft connection, install several groups of pneumatic push rod assemblies 4 symmetrically on the workbench 2, and install multiple groups of rotary presser foot assemblies 5 symmetrically on both sides of the workbench 2. There are reference grooves 3 and baffles inserted in the reference grooves on both sides, and reference guide rails are provided on the workbench 2, on which the X-axis sliding table 11 is installed, and the X-axis sliding table 11 is connected to the X-axis motor 8 , the Y-axis guide rail is fixed vertically on the X-axis slide table 11, and a Y-axis slide table 16 is installed at both ends of the Y-axis guide rail, and the two Y-axis slide tables 16 are connected to ...

Embodiment 2

[0023] Embodiment 2, with reference to figure 1 , 2 , 3, 5, 6, 7, 8, the pneumatic push rod assembly is replaced by a hydraulic push rod assembly, the hydraulic push rod assembly includes an oil tank 31, and the output pipeline of the oil tank is connected to the regulating valve 32, the protection pump 33, and the pumping motor 34 in sequence , filter 35, pressure regulating valve 36, and then branched to connect the electromagnetic reversing valve 37 and adjustable hydraulic push rod 38, the structure of adjustable hydraulic push rod 38 is similar to that of adjustable pneumatic push rod 30, and the fuel tank is provided with oil filling port 39 , liquid level monitor 40, liquid level gauge 41 and oil temperature monitor 42, the oil tank bottom establishes bypass and connects output pipeline through safety valve 43, and oil tank top establishes bypass and connects output pipeline through unloading electromagnetic valve 44. All the others refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com