Pearl wool heat-sealing machine

A technology of pearl cotton and heat sealing machine, which is applied in the field of plastic processing machinery, can solve the problems of wasting energy, unclear reverse position, waste of liquefied petroleum gas, etc., and achieves the effect of strengthening the cooling effect, avoiding the difficult adjustment of firepower, and making effective use of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] For the convenience of recording, the sitting and standing position of the heat sealing machine master is set as the front, the position opposite to the heat sealing machine master is set as the rear, the direction of the tractor is the right, and the direction opposite to the traction machine is the left.

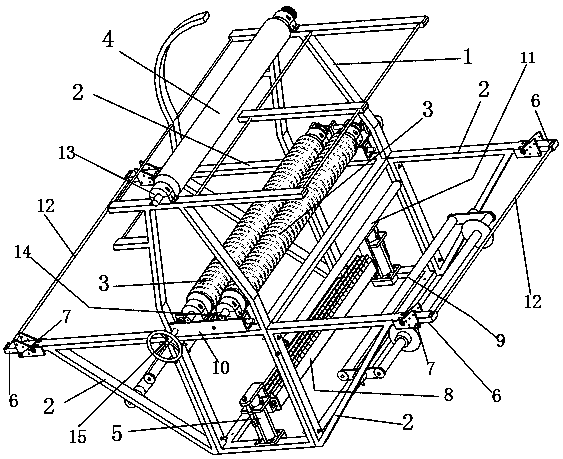

[0060] attached figure 1 It is a schematic diagram of the overall effect of the pearl cotton heat sealing machine, which is attached figure 1 Among them, 1 is the frame, 2 is the tripod, 3 is the roller three, 4 is the roller four, 5 is the pneumatic motor, 6 is the height adjustment plate, 7 is the bolt seven, 8 is the brazier, 9 is the pearl cotton adjustment rod, and 10 is the Sliding plate, 11 is rolling shaft, and 12 is iron rod, and 13 is bearing box one three, and 14 is bearing box one four, and 15 is handle bar, and frame 1 is the basic structure of pearl cotton heat sealing machine, and 4 columns 107 are installed tripods respectively 2,

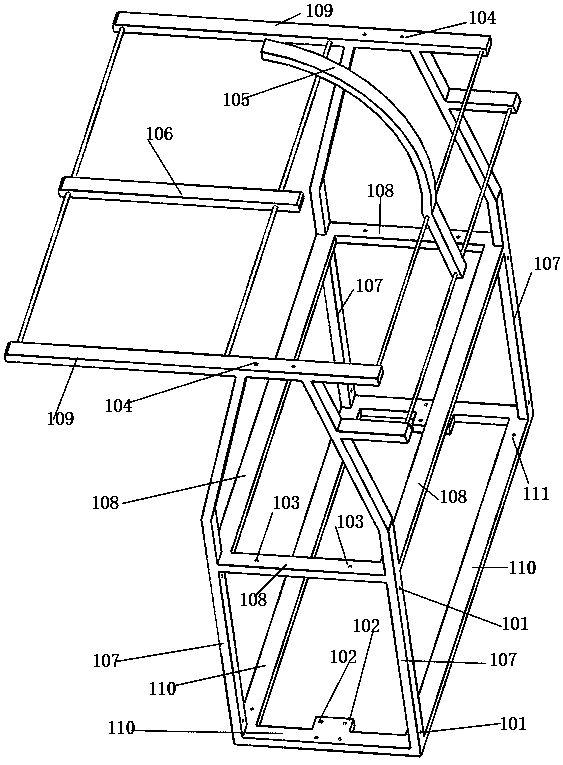

[0061] attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap