Quad-rotor unmanned aerial vehicle with pure belt drive

A four-rotor unmanned aerial vehicle and belt transmission technology, which is applied to rotorcraft, transmission devices to drive multiple propellers, motor vehicles, etc., can solve the problems of increasing the weight of the fuselage transmission system, unsuitable maintenance, and weakened endurance. Achieve the effect of reducing the number of engines and overall body weight, facilitating maintenance and portability, and increasing battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

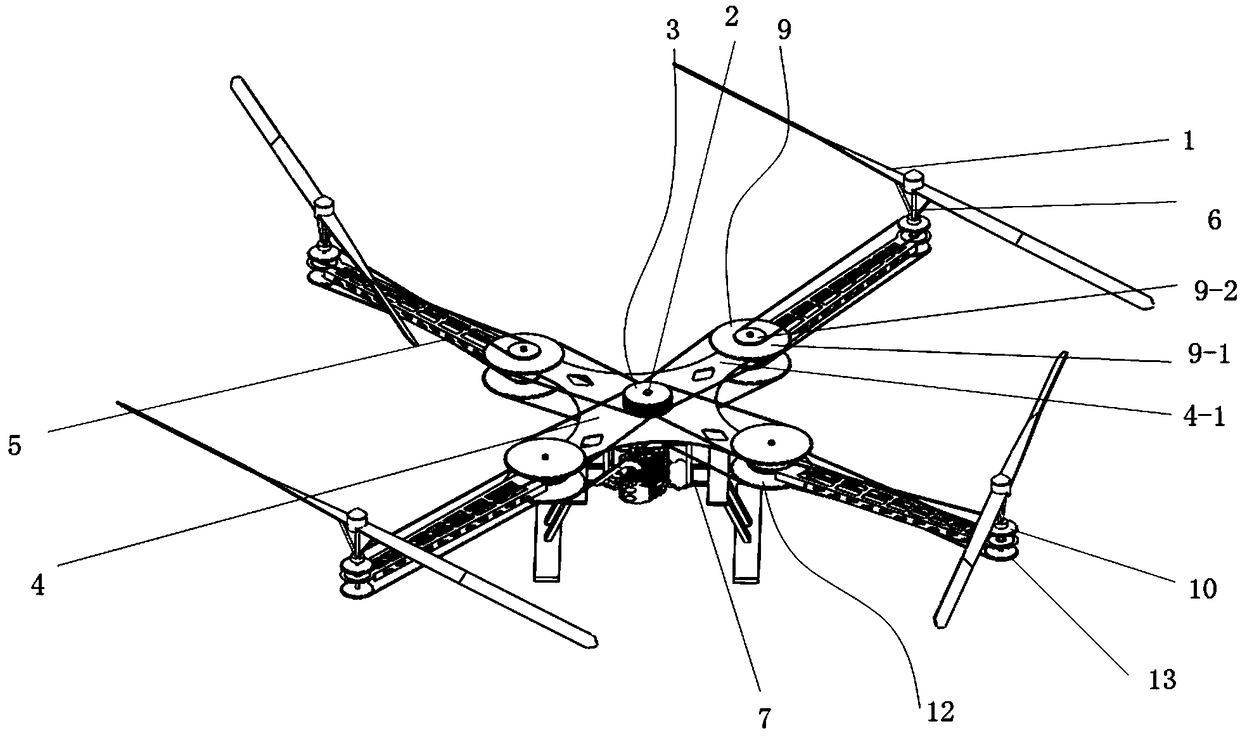

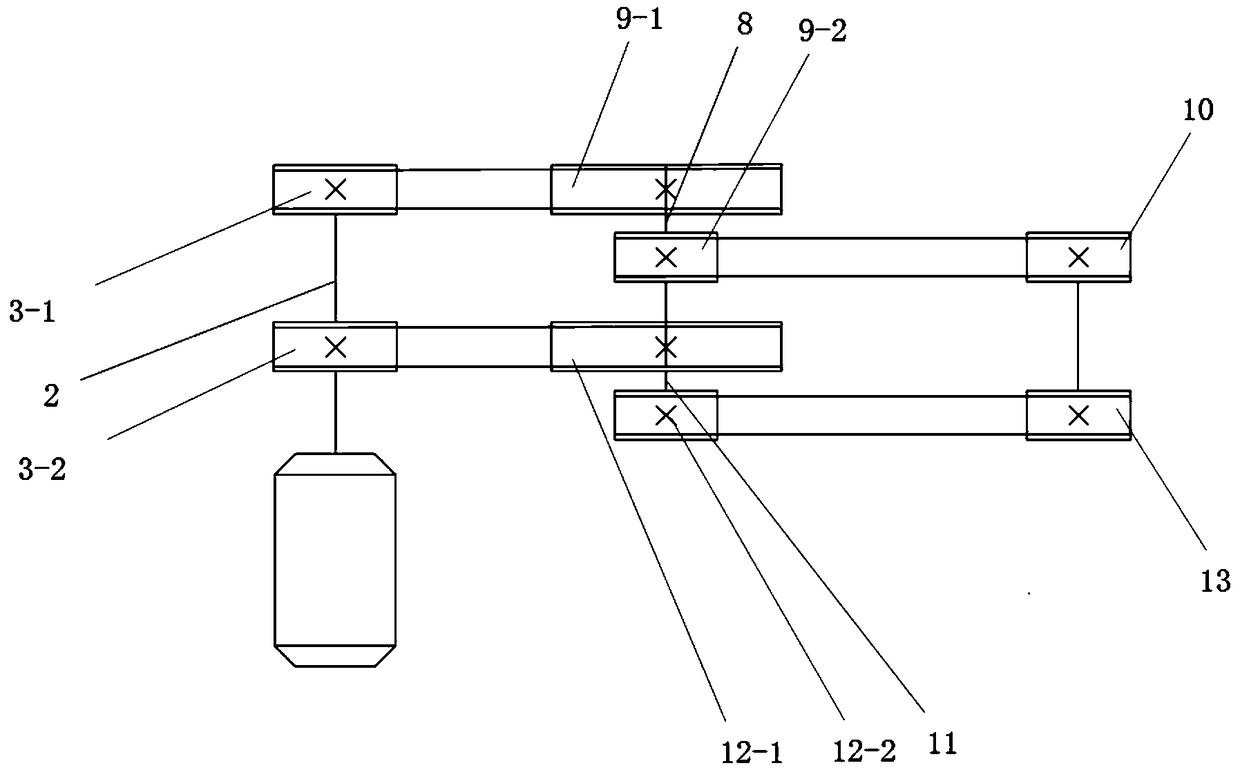

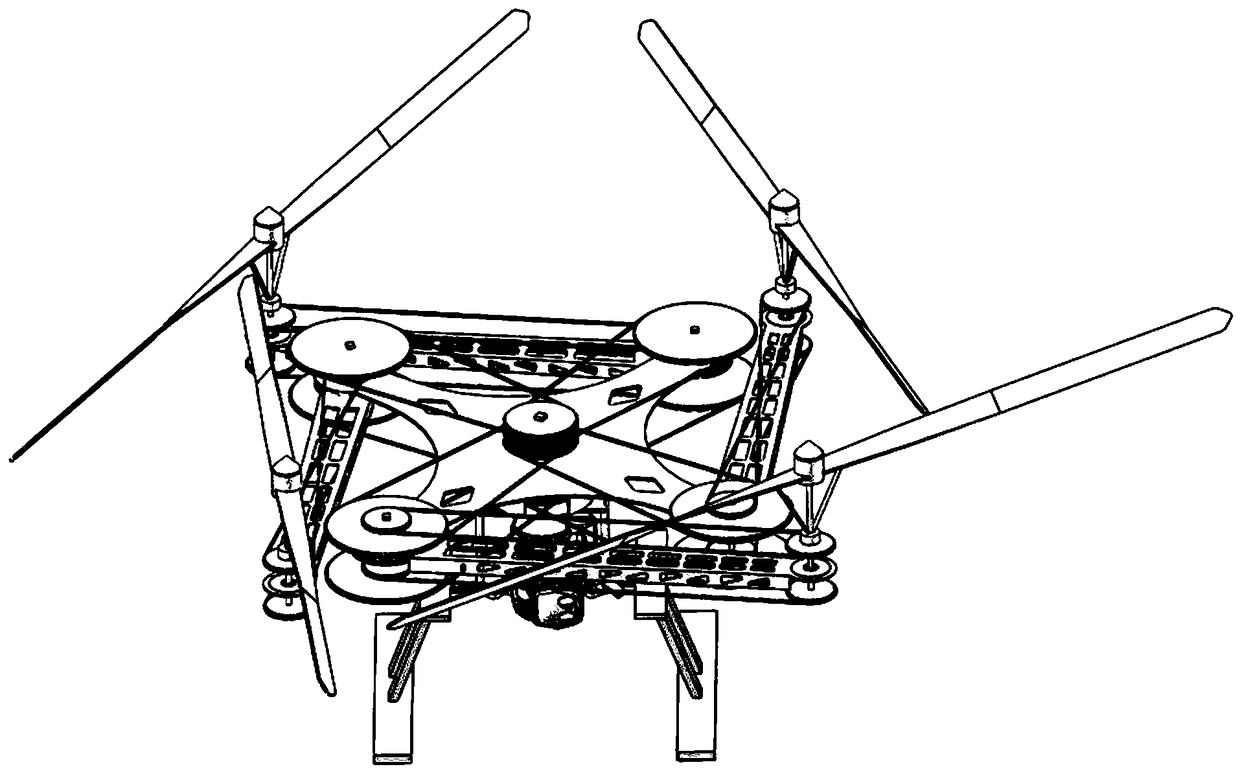

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the transmission of the single-group pure belt transmission assembly of the present invention, image 3 It is a structural schematic diagram (top view) after folding of the present invention, Figure 4 It is a schematic diagram (bottom view) of the folded structure of the present invention, as shown in the figure: a four-rotor UAV with pure belt transmission in this embodiment includes a body, a driving device arranged on the body, and a four-rotor wheel mounted on the body in rotation. The pure belt transmission system between the rotor 1 and the transmission connection drive device and the rotor 1, the pure belt transmission system includes four groups of pure belt transmission components, and each group of pure belt transmission components is connected to each rotor 1 in a one-to-one corresponding manner. Between the driving device and the rotor 1, the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com