Spring inspection switch and inspection method

A technology for detecting switches and pogo pins, which is applied in the directions of automatic packaging control, packaging, and packaging protection. It can solve problems such as bagless blanking and non-normal operation, and achieve the effects of less space, low error rate, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

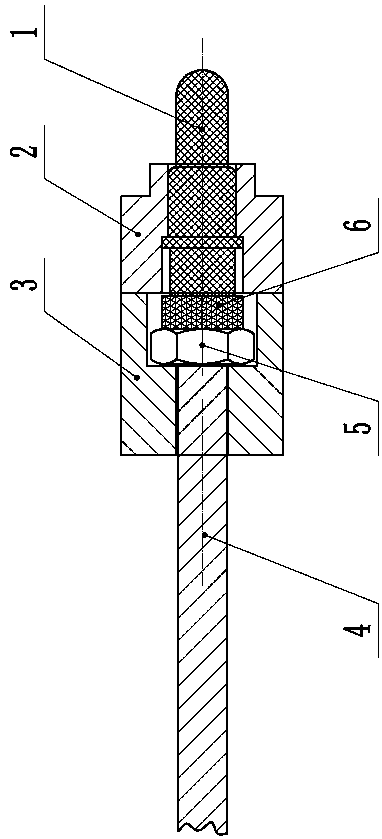

[0015] A spring detection switch, which consists of: a wire 4, the wire and the pogo pin 1 are welded together through a solder contact 6, the pogo pin is installed in the front end cover 2, and the front end cover is connected to the The back seat 3 is connected, the wire passes through the back seat, and a nut 5 is installed between the back seat and the solder contact.

Embodiment 2

[0017] A detection method using the spring detection switch described in claim 1. The gripper on the mechanical arm needs to grip a bag. Whether the bag is successfully gripped by the gripper, the internal control system of the machine will receive a Feedback signal, this feedback signal is sent by the spring detection switch. The specific operation steps are: when the gripper is closed, whether the upper gripper and the lower gripper are insulated, whether the bag is clamped or not, the upper gripper is equivalent to a For the docking part of the electrical signal, a spring detection switch is inlaid inside the plane where the lower gripper touches the upper gripper. If the gripper successfully clamps the bag, the spring detection switch of the lower gripper will not touch the upper gripper, that is to say, the spring detection switch No electrical signal is received, and no feedback signal is received by the mechanical control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com