An online detection device and detection method for surface cracks on a conveyor belt

A detection device and conveyor belt technology, applied in the detection field, can solve problems such as mine coal transportation paralysis, unfavorable manual movement, fracture, etc., achieve wide application and development prospects, promote the development of automated operations, and change the effect of detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

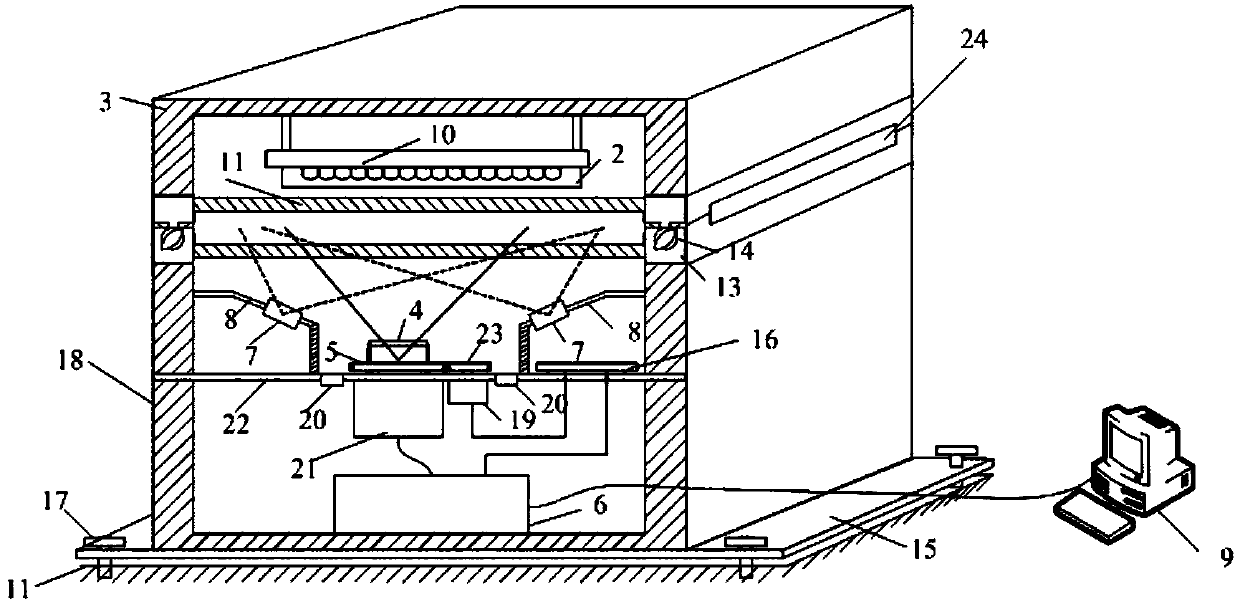

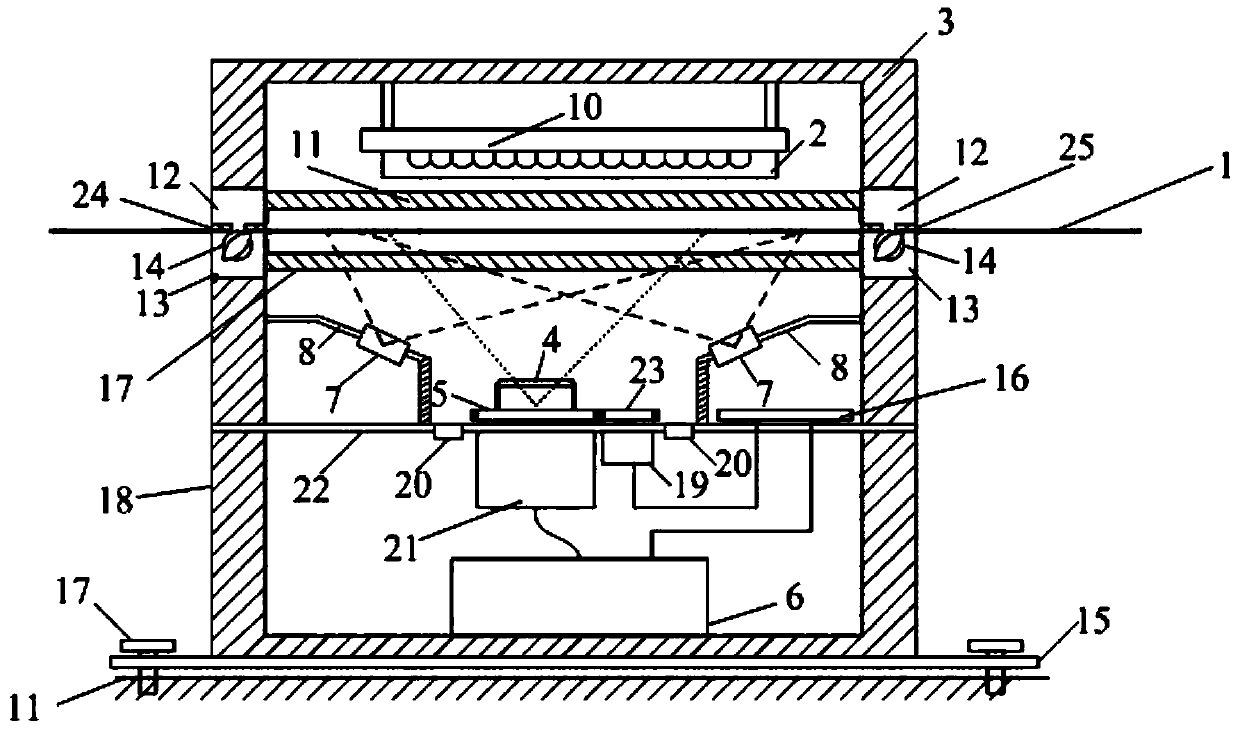

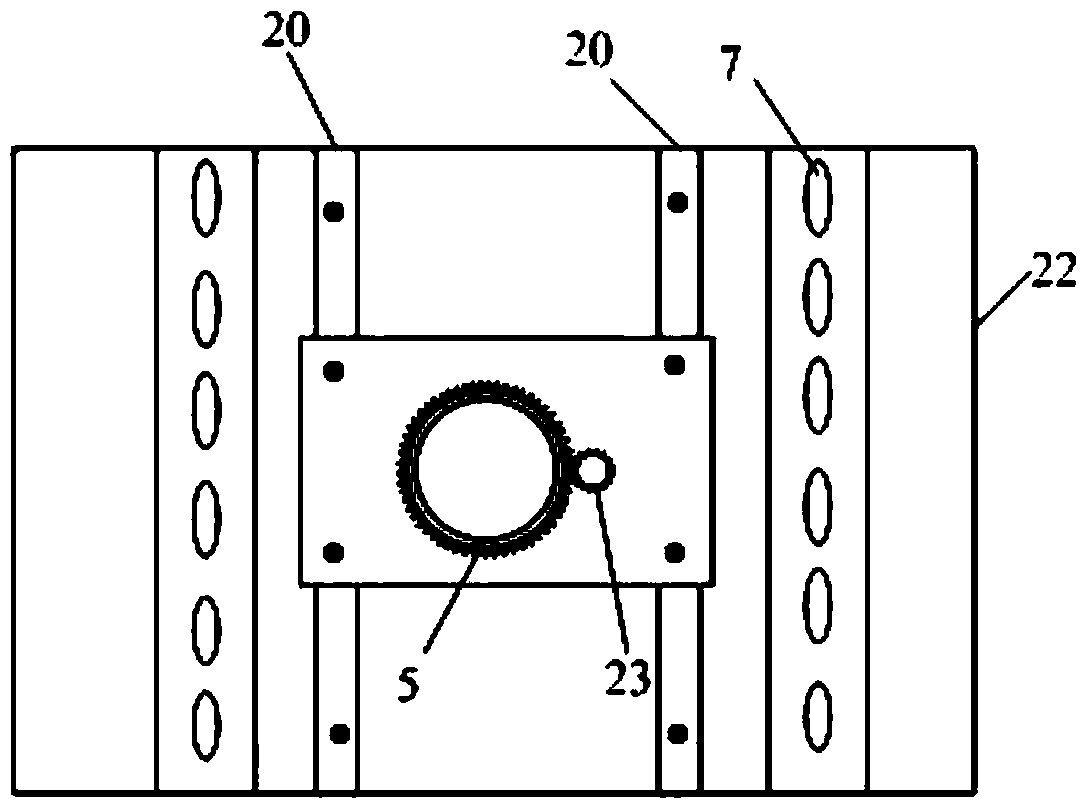

[0028] like figure 1 and 2 as shown, figure 1 and 2 Shown is an online detection device for surface cracks on a conveyor belt, which includes a main frame, a background light source 10, a projection light source 7, an area array CCD camera 21, and a processing industrial computer 6, wherein the main frame includes an upper frame 3 and a lower frame 18. The main frame is installed on the horizontal ground 11 at the position where the conveyor belt can be detected through the mounting base 15, and the height of the main frame relative to the horizontal ground 11 can be adjusted through the height knobs 17 at the four corners of the mounting base 15, so that the online detection device The position, especially the height can be adjusted more flexibly.

[0029] The upper frame 3 and the lower frame 18 are fixedly connected together by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com