Wire terminal protection cover

A wire harness terminal and protective cover technology, which is applied in the field of wire harness terminal protective cover, can solve the problems of complex structure and time-consuming operation process, and achieve the effect of reducing the occupied space and convenient and fast clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

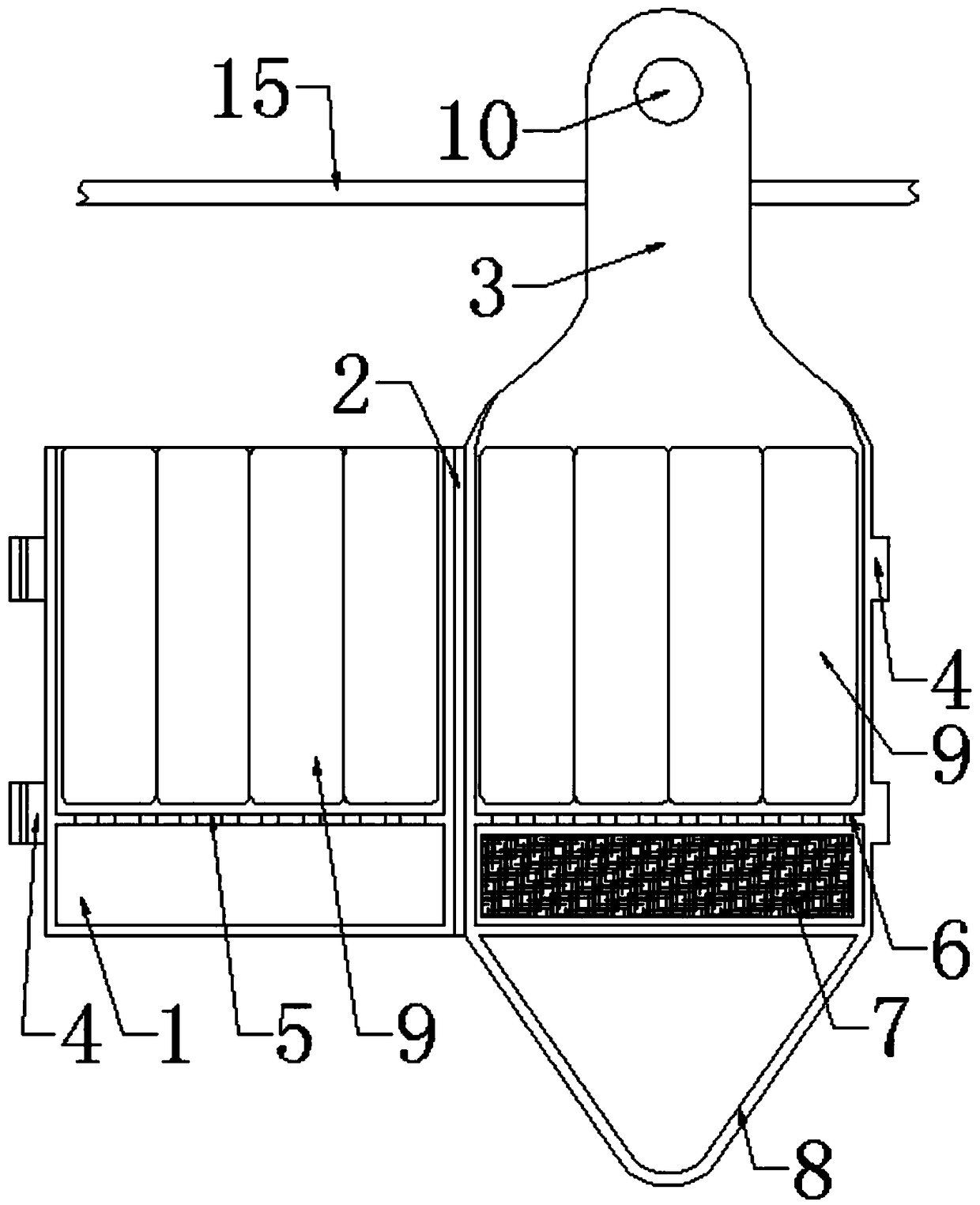

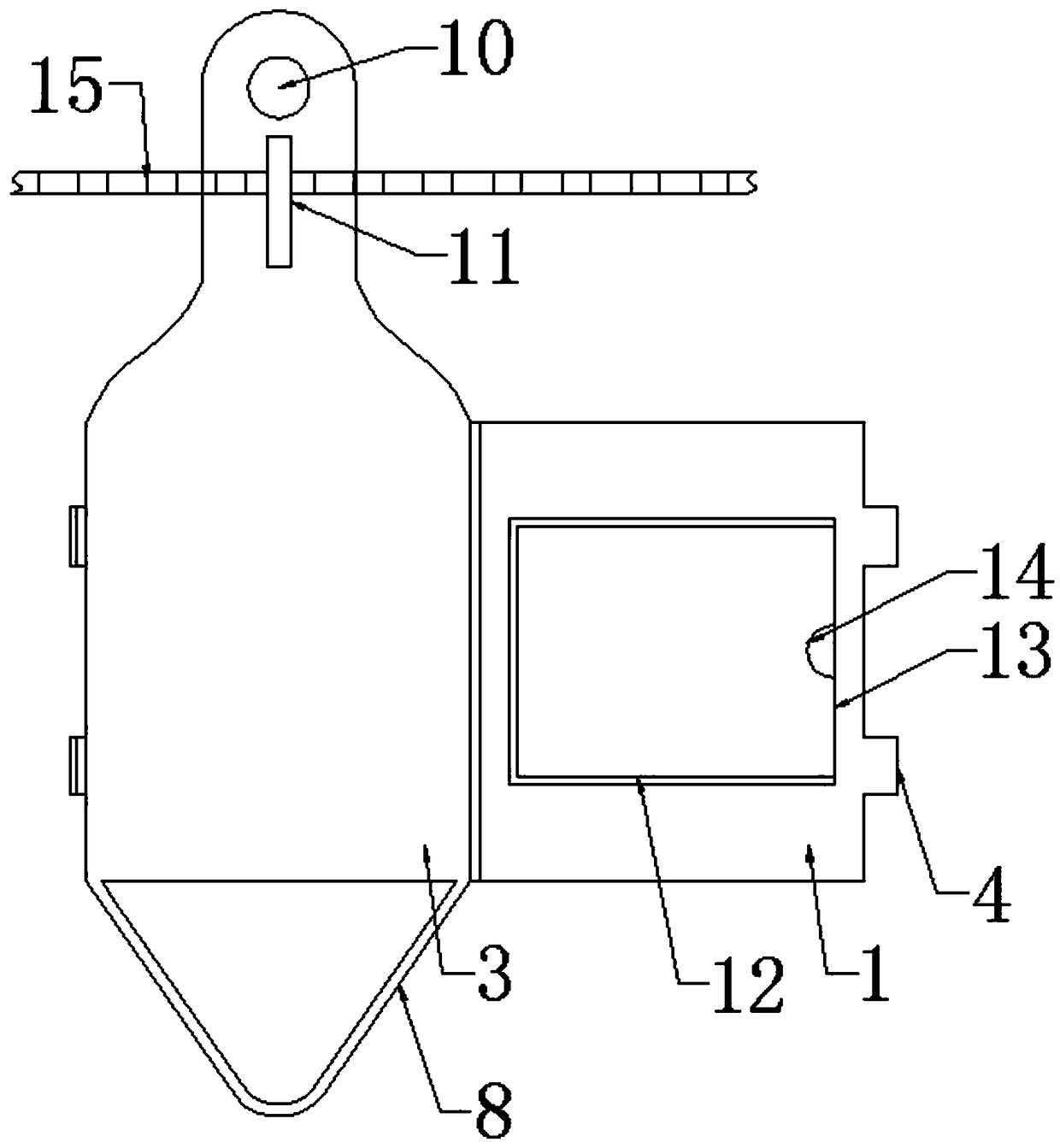

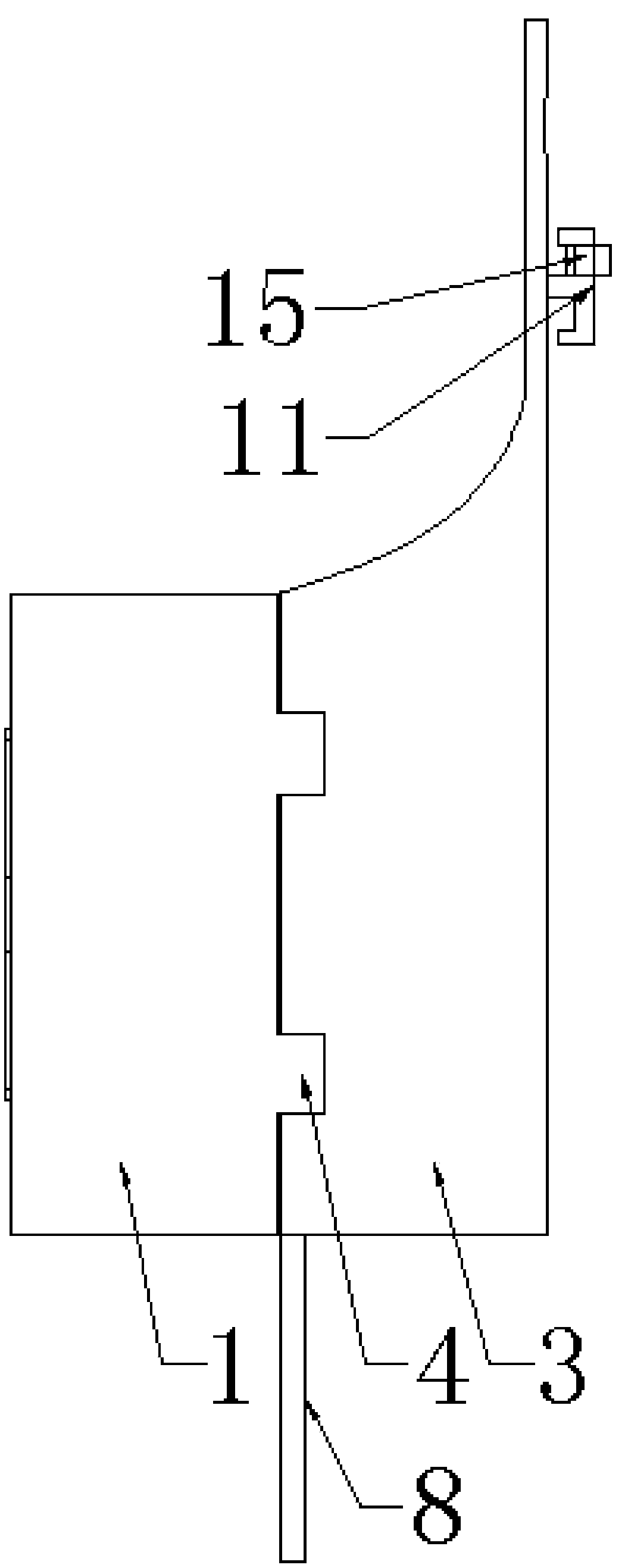

[0023] Such as Figure 1 to Figure 5 As shown, a wire harness terminal protection cover includes a front shell 1 and a rear shell 3, a connecting block 2 is provided between the front shell 1 and the rear shell 3, and the other side of the front shell 1 and the rear shell 3 passes through The buckle 4 is connected to form an annular cover, the inside of the front shell 1 is provided with a front shell partition 5, the inside of the rear shell 3 is provided with a rear shell partition 6, and the front shell partition 5 and The back shell partition plate 6 is at the same height position, and on the front shell partition plate 5 and the rear shell partition plate 6, through holes are evenly distributed, and the front shell partition plate 5 and the rear shell partition plate 6 divide the inside of the cover into There are upper and lower chambers, the inner wall of the upper chamber is evenly provided with buffer pads 9, and the lower chamber is provided with a desiccant 7.

[0...

Embodiment 2

[0030] Such as Figure 1 to Figure 5 As shown, a wire harness terminal protective cover includes a front shell 1 and a rear shell 3, a connecting block 2 is provided between the front shell 1 and the rear shell 3, and the other side of the front shell 1 and the rear shell 3 A buckle 4 is provided to connect and form an annular cover, the inside of the front shell 1 is provided with a front shell partition 5, the inside of the rear shell 3 is provided with a rear shell partition 6, and the front shell partition 5 and the back shell partition plate 6 are at the same height position, and are evenly distributed with through holes on the front shell partition plate 5 and the rear shell partition plate 6, the front shell partition plate 5 and the rear shell partition plate 6 will cover the inside Divided into upper and lower chambers, the inner wall of the upper chamber is uniformly provided with buffer pads 9, and the lower chamber is provided with desiccant 7.

[0031] In the pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap